Question: Value stream mapping involves first developing a baseline map of the current situation of a companys external and/or internal operations, and then applying lean concepts,

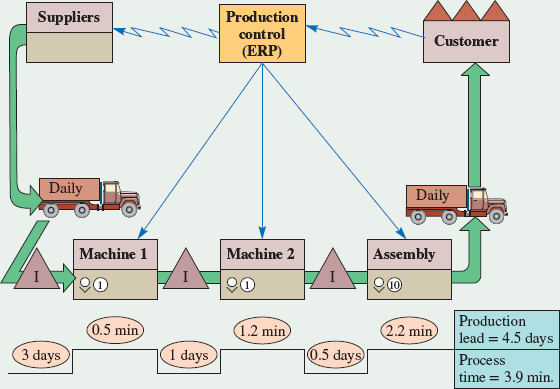

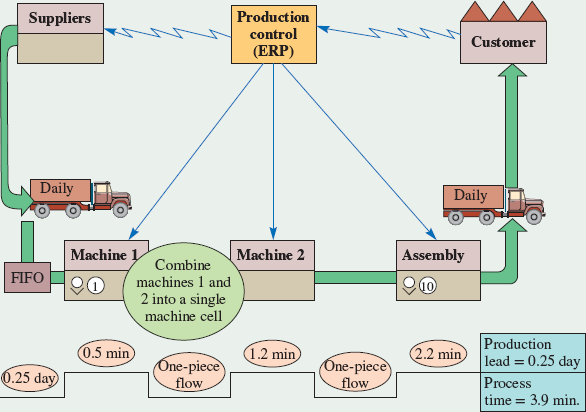

Value stream mapping involves first developing a baseline map of the current situation of a companys external and/or internal operations, and then applying lean concepts, developing a future state map that shows improved operations. Exhibit 12.16, for example, shows the current state with a production lead time of 4.5 days. This system is a batch/push system (indicated by striped arrows) resulting in long delays and inventory buildups. Exhibit 12.17 shows the future state map with a production lead time of 0.25 day. This was accomplished by moving to a continuous-flow pull system and attacking the seven wastes. Value stream mapping uses a number of special icons and a display format of boxes and flows.

Questions *** please answer the following questions *****

1. Eliminating the queue of work dramatically quickens the time it takes a part to flow through the system. What are the disadvantages of removing those queues?

2. How do you think the machine operators would react to the change?

3. What would you do to ensure that the operators were kept busy?

Exhibit 12.16 Map of the Current State

Exhibit 12.17 Map of The Future State

Please provide any sources used ... please provide help with the questions above. Thank you

Suppliers Production control (ERP) Customer Daily Daily Machine 1 Assembly Machine 2 90 0.5 min (1.2 min (2.2 min 3 days 1 days 0.5 days Production lead = 4.5 days Process time = 3.9 min. Suppliers Production control (ERP) Customer Daily Daily FIFO Machine 1 Machine 2 Combine machines 1 and 2 into a single machine cell Assembly 10 0.5 min (1.2 min 2.2 min 0.25 day One-piece flow One-piece flow Production lead = 0.25 day Process time = 3.9 minStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts