Question: Value stream mapping involves first developing a baseline map of the current situation of a companys external and/or internal operations, and then applying lean concepts,

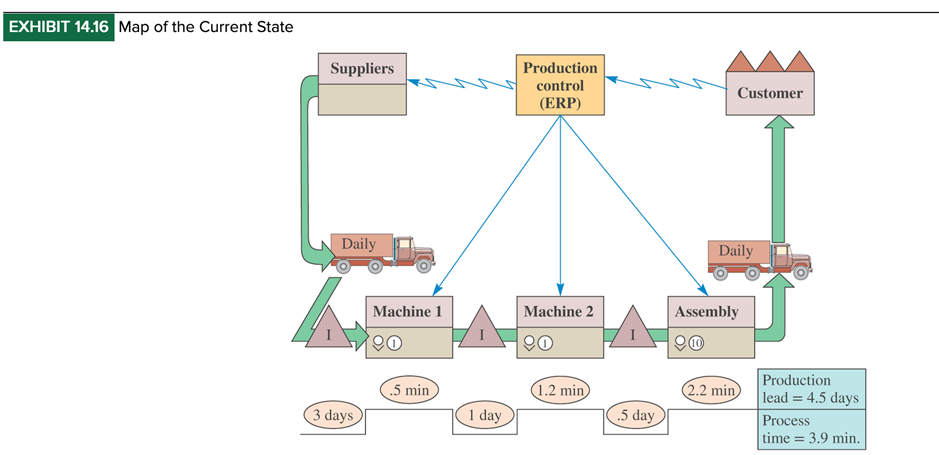

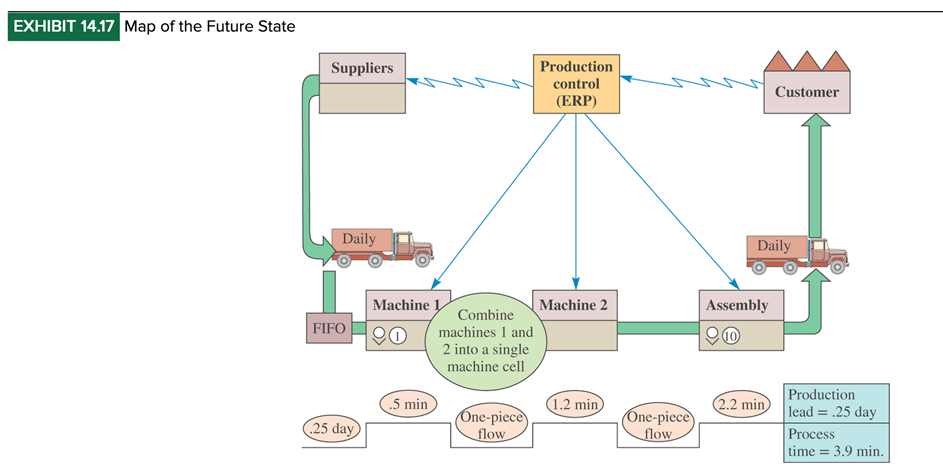

Value stream mapping involves first developing a baseline map of the current situation of a companys external and/or internal operations, and then applying lean concepts, developing a future state map that shows improved operations. Exhibit 14.16, for example, shows the current state with a production lead time of 4.5 days. This system is a batch/push system, resulting in long delays and inventory buildups. Exhibit 14.17 shows the future state map with a production lead time of 0.25 day. This was accomplished by moving to a continuous-flow pull system and attacking the seven wastes.

- Eliminating the queue of work dramatically quickens the time it takes a part to flow through the system. What are the disadvantages of removing those queues?

- How do you think the machine operators would react to the change?

- What would you do to ensure that the operators were kept busy?

Map of the Current Ctsto Map of the Future Ctatn

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts