Question: Warehousing Case Study The Howard Smith Paper Group The Howard Smith Paper Group operates the most advanced warehousing operation within the European paper merchanting sector,

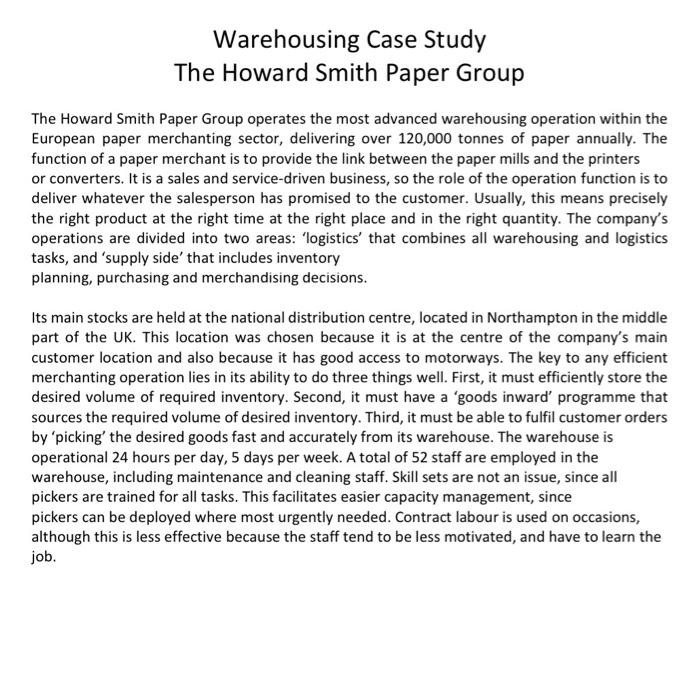

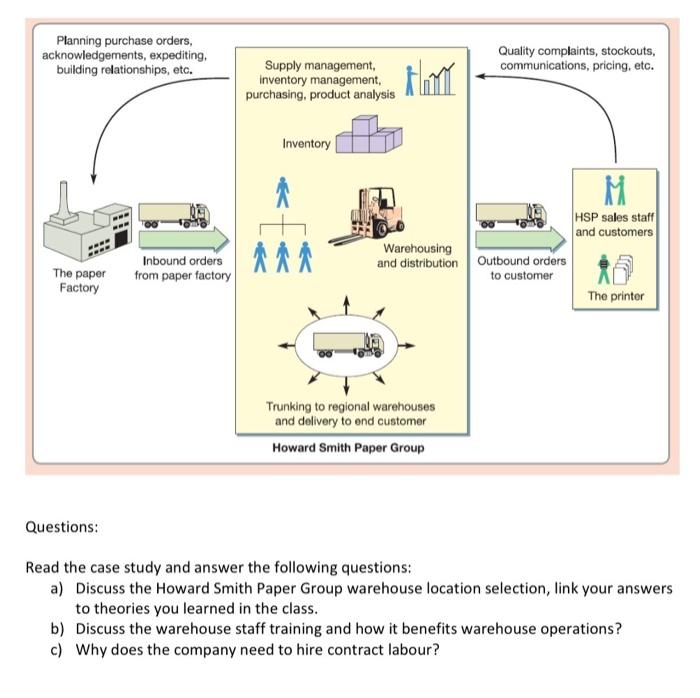

Warehousing Case Study The Howard Smith Paper Group The Howard Smith Paper Group operates the most advanced warehousing operation within the European paper merchanting sector, delivering over 120,000 tonnes of paper annually. The function of a paper merchant is to provide the link between the paper mills and the printers or converters. It is a sales and service-driven business, so the role of the operation function is to deliver whatever the salesperson has promised to the customer. Usually, this means precisely the right product at the right time at the right place and in the right quantity. The company's operations are divided into two areas: 'logistics' that combines all warehousing and logistics tasks, and 'supply side' that includes inventory planning, purchasing and merchandising decisions. Its main stocks are held at the national distribution centre, located in Northampton in the middle part of the UK. This location was chosen because it is at the centre of the company's main customer location and also because it has good access to motorways. The key to any efficient merchanting operation lies in its ability to do three things well. First, it must efficiently store the desired volume of required inventory. Second, it must have a 'goods inward' programme that sources the required volume of desired inventory. Third, it must be able to fulfil customer orders by 'picking the desired goods fast and accurately from its warehouse. The warehouse is operational 24 hours per day, 5 days per week. A total of 52 staff are employed in the warehouse, including maintenance and cleaning staff. Skill sets are not an issue, since all pickers are trained for all tasks. This facilitates easier capacity management, since pickers can be deployed where most urgently needed. Contract labour is used on occasions, although this is less effective because the staff tend to be less motivated, and have to learn the job. Planning purchase orders, acknowledgements, expediting, building relationships, etc. Quality complaints, stockouts, communications, pricing, etc. Supply management, inventory management, purchasing, product analysis tommy Inventory M Inbound orders from paper factory *** HSP sales staff and customers Warehousing and distribution Outbound orders to customer The printer The paper Factory Trunking to regional warehouses and delivery to end customer Howard Smith Paper Group Questions: Read the case study and answer the following questions: a) Discuss the Howard Smith Paper Group warehouse location selection, link your answers to theories you learned in the class. b) Discuss the warehouse staff training and how it benefits warehouse operations? c) Why does the company need to hire contract labour? Warehousing Case Study The Howard Smith Paper Group The Howard Smith Paper Group operates the most advanced warehousing operation within the European paper merchanting sector, delivering over 120,000 tonnes of paper annually. The function of a paper merchant is to provide the link between the paper mills and the printers or converters. It is a sales and service-driven business, so the role of the operation function is to deliver whatever the salesperson has promised to the customer. Usually, this means precisely the right product at the right time at the right place and in the right quantity. The company's operations are divided into two areas: 'logistics' that combines all warehousing and logistics tasks, and 'supply side' that includes inventory planning, purchasing and merchandising decisions. Its main stocks are held at the national distribution centre, located in Northampton in the middle part of the UK. This location was chosen because it is at the centre of the company's main customer location and also because it has good access to motorways. The key to any efficient merchanting operation lies in its ability to do three things well. First, it must efficiently store the desired volume of required inventory. Second, it must have a 'goods inward' programme that sources the required volume of desired inventory. Third, it must be able to fulfil customer orders by 'picking the desired goods fast and accurately from its warehouse. The warehouse is operational 24 hours per day, 5 days per week. A total of 52 staff are employed in the warehouse, including maintenance and cleaning staff. Skill sets are not an issue, since all pickers are trained for all tasks. This facilitates easier capacity management, since pickers can be deployed where most urgently needed. Contract labour is used on occasions, although this is less effective because the staff tend to be less motivated, and have to learn the job. Planning purchase orders, acknowledgements, expediting, building relationships, etc. Quality complaints, stockouts, communications, pricing, etc. Supply management, inventory management, purchasing, product analysis tommy Inventory M Inbound orders from paper factory *** HSP sales staff and customers Warehousing and distribution Outbound orders to customer The printer The paper Factory Trunking to regional warehouses and delivery to end customer Howard Smith Paper Group Questions: Read the case study and answer the following questions: a) Discuss the Howard Smith Paper Group warehouse location selection, link your answers to theories you learned in the class. b) Discuss the warehouse staff training and how it benefits warehouse operations? c) Why does the company need to hire contract labour