Question: was screen shot in google but like to learn how to do this. Consider the above assembly process map. 1) What is the takt time?

was screen shot in google but like to learn how to do this.

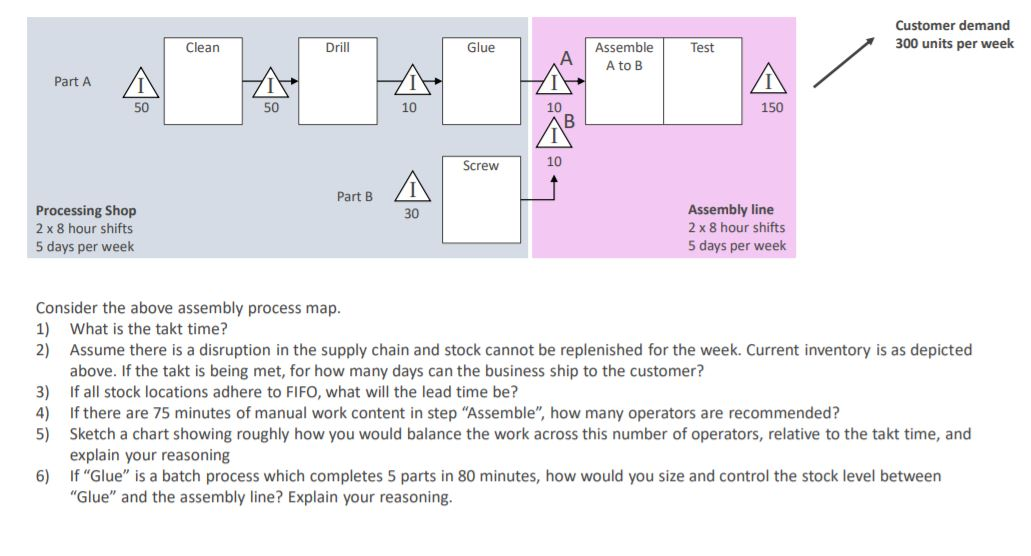

Consider the above assembly process map. 1) What is the takt time? 2) Assume there is a disruption in the supply chain and stock cannot be replenished for the week. Current inventory is as depicted above. If the takt is being met, for how many days can the business ship to the customer? 3) If all stock locations adhere to FIFO, what will the lead time be? 4) If there are 75 minutes of manual work content in step Assemble, how many operators are recommended? 5) Sketch a chart showing roughly how you would balance the work across this number of operators, relative to the takt time, and explain your reasoning 6) If Glue is a batch process which completes 5 parts in 80 minutes, how would you size and control the stock level between Glue and the assembly line? Explain your reasoning.

Anything not mentioned, need to be assumption as this is the question with all details

Customer demand 300 units per week Clean Drill Glue Test Assemble A to B Part A 1 50 50 10 10 150 4439 Screw 10 A Part B 30 Processing Shop 2 x 8 hour shifts 5 days per week Assembly line 2 x 8 hour shifts 5 days per week Consider the above assembly process map. 1) What is the takt time? 2) Assume there is a disruption in the supply chain and stock cannot be replenished for the week. Current inventory is as depicted above. If the takt is being met, for how many days can the business ship to the customer? 3) If all stock locations adhere to FIFO, what will the lead time be? 4) If there are 75 minutes of manual work content in step "Assemble", how many operators are recommended? 5) Sketch a chart showing roughly how you would balance the work across this number of operators, relative to the takt time, and explain your reasoning 6) If "Glue" is a batch process which completes 5 parts in 80 minutes, how would you size and control the stock level between "Glue" and the assembly line? Explain your reasoning. Customer demand 300 units per week Clean Drill Glue Test Assemble A to B Part A 1 50 50 10 10 150 4439 Screw 10 A Part B 30 Processing Shop 2 x 8 hour shifts 5 days per week Assembly line 2 x 8 hour shifts 5 days per week Consider the above assembly process map. 1) What is the takt time? 2) Assume there is a disruption in the supply chain and stock cannot be replenished for the week. Current inventory is as depicted above. If the takt is being met, for how many days can the business ship to the customer? 3) If all stock locations adhere to FIFO, what will the lead time be? 4) If there are 75 minutes of manual work content in step "Assemble", how many operators are recommended? 5) Sketch a chart showing roughly how you would balance the work across this number of operators, relative to the takt time, and explain your reasoning 6) If "Glue" is a batch process which completes 5 parts in 80 minutes, how would you size and control the stock level between "Glue" and the assembly line? Explain your reasoningStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts