Question: We have three main steps in this process - extraction, filtering, and bottling. Our extraction and bottling tasks don't require setup time, while the

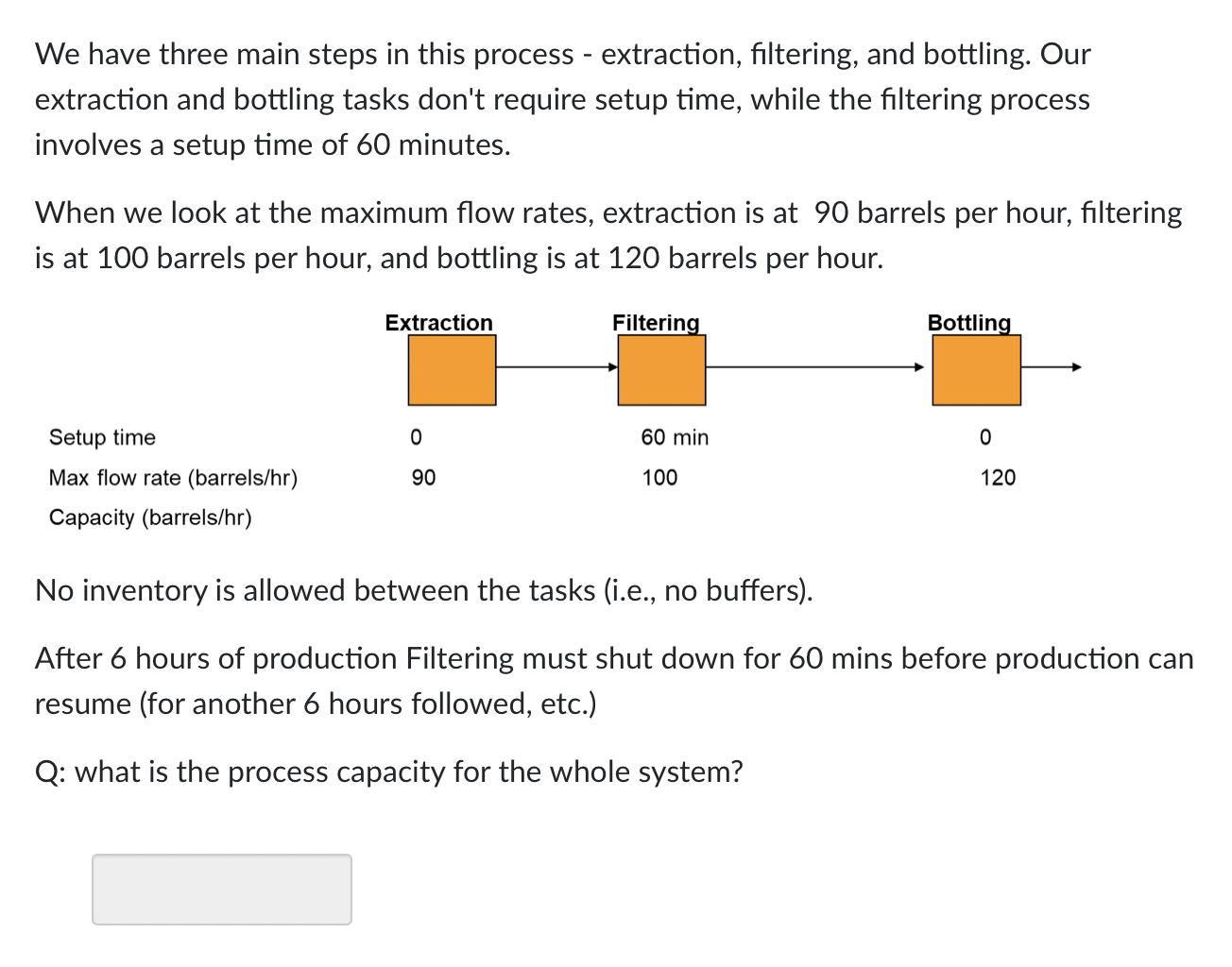

We have three main steps in this process - extraction, filtering, and bottling. Our extraction and bottling tasks don't require setup time, while the filtering process involves a setup time of 60 minutes. When we look at the maximum flow rates, extraction is at 90 barrels per hour, filtering is at 100 barrels per hour, and bottling is at 120 barrels per hour. Setup time Max flow rate (barrels/hr) Capacity (barrels/hr) Extraction 0 90 Filtering 60 min 100 Bottling 0 120 No inventory is allowed between the tasks (i.e., no buffers). After 6 hours of production Filtering must shut down for 60 mins before production can resume (for another 6 hours followed, etc.) Q: what is the process capacity for the whole system?

Step by Step Solution

3.52 Rating (166 Votes )

There are 3 Steps involved in it

To calculate the process capacity for the whole system we need to consider each steps maximum flow r... View full answer

Get step-by-step solutions from verified subject matter experts