Question: We Solved this question and the wrong answer is below. But our teacher said that its wrong and said like that : Everyone solved it

We Solved this question and the wrong answer is below. But our teacher said that its wrong and said like that : Everyone solved it as a newsboy problem, but the problem is the annual R Q policy problem, I would like to review the formulations and correct your mistakes. Please Solve as the teacher wants

Annual demand (D) = 6000

Cost of units (C) = 20

Annual holding cost (H) = 30% of 20 = 6

Ordering cost (S) = 150

Cost of overstocking (Co) = 6

Cost of understocking (Cu) = 50-20 = 30

Optimum service level = Cu/(Cu+Co) = 30/36) = 83.33%

The z value for service level = 0.96

Average demand during lead time (d) = (100+200)/2 = 150

Variance of demand during lead time (sigmasq) = (200-100)^2/12 = 833.33

Standard deviation of demand during lead time (sigma) = sqrt(833) = 28.86

Q = sqrt(2DS/H) = sqrt(2*6000*150/6) = 547.7 or 548 units

R = d*L + safety stock

Since there is no lead time mentioned, we only need to consider the safety stock for lead time of 1. That is

SS = z*sigma*sqrt(L) = 0.96*28.86 = 27.7

The Reorder point (R) = 150 + 27.7 = 177.7 or 178 units

The total cost = inventory cost + stockout cost

Inventory cost = HQ/2 + DS/Q = 6*548/2 + 6000*150/548 = 3286.3

Stockout cost = (1-0.8333)*150*50 = 1250.25

Total cost = 3286.3 + 1250.25 = 4536.55

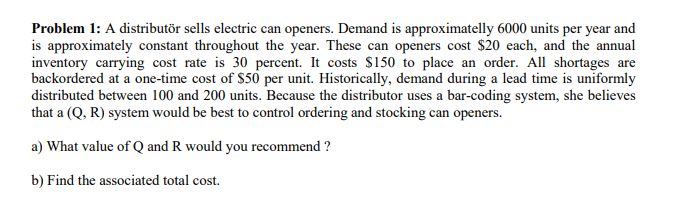

Problem 1: A distributr sells electric can openers. Demand is approximatelly 6000 units per year and is approximately constant throughout the year. These can openers cost $20 each, and the annual inventory carrying cost rate is 30 percent. It costs $150 to place an order. All shortages are backordered at a one-time cost of $50 per unit. Historically, demand during a lead time is uniformly distributed between 100 and 200 units. Because the distributor uses a bar-coding system, she believes that a (Q, R) system would be best to control ordering and stocking can openers. a) What value of Q and R would you recommend ? b) Find the associated total cost. Problem 1: A distributr sells electric can openers. Demand is approximatelly 6000 units per year and is approximately constant throughout the year. These can openers cost $20 each, and the annual inventory carrying cost rate is 30 percent. It costs $150 to place an order. All shortages are backordered at a one-time cost of $50 per unit. Historically, demand during a lead time is uniformly distributed between 100 and 200 units. Because the distributor uses a bar-coding system, she believes that a (Q, R) system would be best to control ordering and stocking can openers. a) What value of Q and R would you recommend ? b) Find the associated total cost

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts