Question: What elements in the purchasing function should we measure? added value might take the Torm or operating cost reductions, lower material prices, fewer rejects, better

What elements in the purchasing function should we measure?

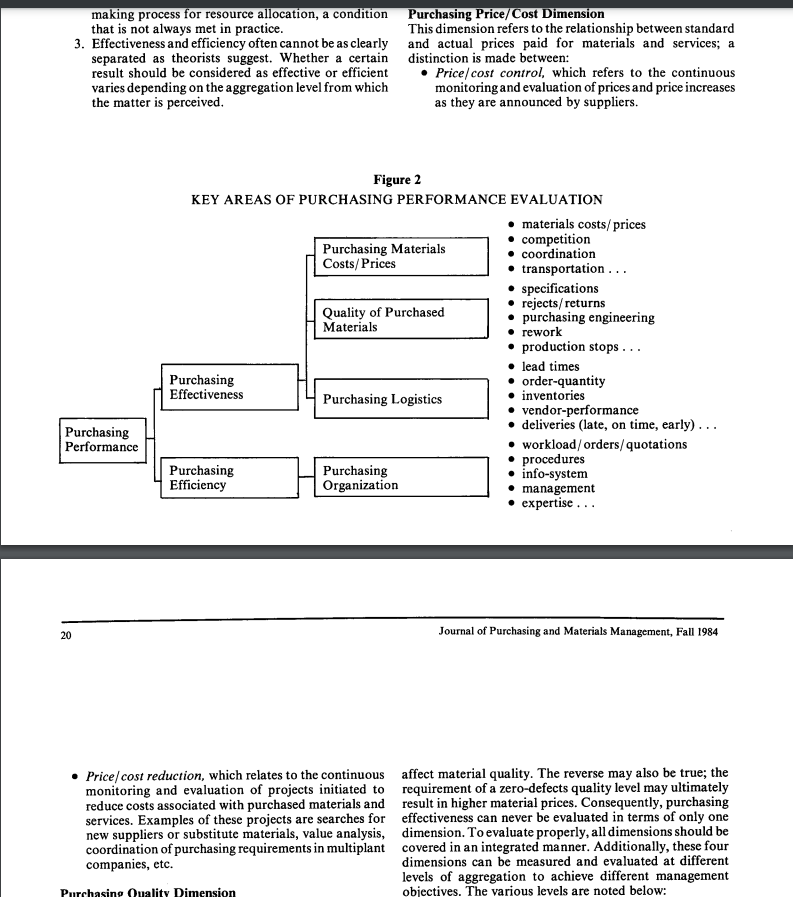

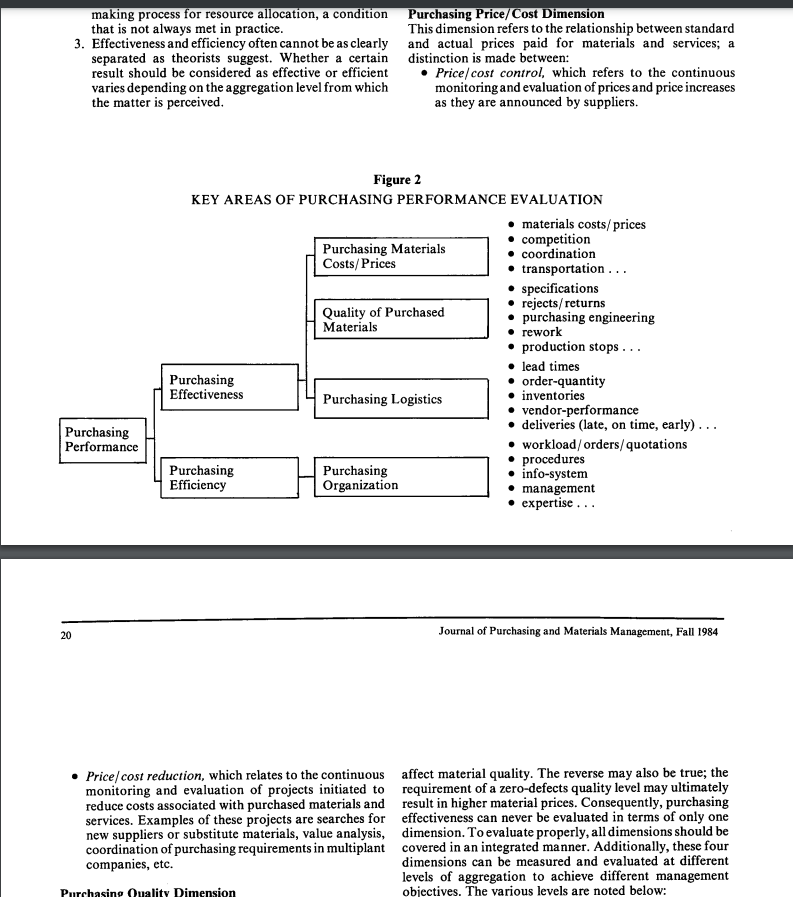

added value might take the Torm or operating cost reductions, lower material prices, fewer rejects, better of reference for future action, must be judgmentally sourcing decisions, etc. determined. In the author's view, purchasing performance should be evaluated regularly for two reasons. First, performance WHAT SHOULD BE MEASURED? evaluation should be conducted to rate the individual In order to decide what should be measured, it is necessary buyer. In this sense, measurement is used primarily to serve first to define purchasing performance. For purposes of the purposes of functional and individual control. Second, this study, purchasing performance is considered to be the systematic performance assessment should serve the pur- result of two elements--purchasing effectiveness and pur- pose of self-appraisal. In this sense, improvement of chasing efficiency. purchasing activities can be achieved most effectively by Purchasing effectiveness is defined as the extent to enabling each buyer to assess the results of his or her own which, by choosing a certain course of action, a previously purchasing activities. Hence, the evaluation activity is established goal or standard can be met. It is important to directed toward support of the individual buyer in doing a recognize that effectiveness essentially refers to the relation- better professional job. Since purchasing performance ship between actual and planned performance of any standards cannot be established with precision and uni- human activity. A selected course of action is either formity, this author helieves that the second reason is by effective or not-a goal is reached or not. However, the far the most important and useful to a practicing manager. goal can be expressed in terms of aspiration levels; the 19 course of action that realizes a higher level may then be Effectiveness thus is related to the objectives of the considered as more effective than another. purchasing function. The classical statement summarizing Purchasing efficiency is defined as the relationship the overall objectives of the purchasing function is that it between planned and actual sacrifices made in order to be should obtain the right material, in the right quantity, from able to realize a goal previously agreed upon. It is the right source, for delivery at the right time and right important to recognize that efficiency is related to the place, with the right service and at the right price. resources/means selected. Essentially it refers to the Based on this widely accepted statement, four key areas relationship between two kinds of costs. in purchasing performance evaluation can be identified: Purchasing performance thus can be considered as the extent to which the purchasing function is able to realize its Purchasing Price/Cost Dimension Purchasing Quality Dimension predetermined goals at the sacrifice of a minimum of the company's resources. Several qualifying comments must Purchasing Logistics Dimension be made: Purchasing Organization Dimension The first three dimensions relate to purchasing effective- 1. This definition is in no way operational; it serves ness, whereas the purchasing organization in fact relates to rather as a term of referencethat is, as a way in the resources through which the purchasing objectives are which purchasing performance can be viewed. It realized. Hence, it relates primarily to purchasing efficiency. recognizes the fact that any purchasing organization, These relationships are detailed in Figure 2. The four key in order to be effective, should have formulated its areas of purchasing performance evaluation are described goals. in more detail in the following sections. 2. This definition assumes a rather rational decision- making process for resource allocation, a condition Purchasing Price/Cost Dimension that is not always met in practice. This dimension refers to the relationship between standard 3. Effectiveness and efficiency often cannot be as clearly and actual prices paid for materials and services; a WILL making process for resource allocation, a condition Purchasing Price/Cost Dimension that is not always met in practice. This dimension refers to the relationship between standard 3. Effectiveness and efficiency often cannot be as clearly and actual prices paid for materials and services; a separated as theorists suggest. Whether a certain distinction is made between: result should be considered as effective or efficient Price/cost control, which refers to the continuous varies depending on the aggregation level from which monitoring and evaluation of prices and price increases the matter is perceived, as they are announced by suppliers. Figure 2 KEY AREAS OF PURCHASING PERFORMANCE EVALUATION materials costs/prices competition Purchasing Materials coordination Costs/Prices transportation ... specifications rejects/returns Quality of Purchased Materials purchasing engineering rework production stops... lead times Purchasing order-quantity Effectiveness Purchasing Logistics inventories vendor-performance deliveries (late, on time, early)... workload/orders/quotations procedures Purchasing Purchasing info-system Efficiency Organization management expertise ... Purchasing Performance 20 Journal of Purchasing and Materials Management, Fall 1984 Price/cost reduction, which relates to the continuous affect material quality. The reverse may also be true; the monitoring and evaluation of projects initiated to requirement of a zero-defects quality level may ultimately reduce costs associated with purchased materials and result in higher material prices. Consequently, purchasing services. Examples of these projects are searches for effectiveness can never be evaluated in terms of only one new suppliers or substitute materials, value analysis, dimension. To evaluate properly, all dimensions should be coordination of purchasing requirements in multiplant covered in an integrated manner. Additionally, these four companies, etc. dimensions can be measured and evaluated at different levels of aggregation to achieve different management Purchasing Quality Dimension objectives. The various levels are noted below: Price/cost reduction, which relates to the continuous affect material quality. The reverse may also be true; the monitoring and evaluation of projects initiated to requirement of a zero-defects quality level may ultimately reduce costs associated with purchased materials and result in higher material prices. Consequently, purchasing services. Examples of these projects are searches for effectiveness can never be evaluated in terms of only one new suppliers or substitute materials, value analysis, dimension. To evaluate properly, all dimensions should be coordination of purchasing requirements in multiplant covered in an integrated manner. Additionally, these four companies, etc. dimensions can be measured and evaluated at different levels of aggregation to achieve different management Purchasing Quality Dimension objectives. The various levels are noted below: Purchasing's responsibility with regard to the quality of purchased materials should not be defined too narrowly. The line-item level Predevelopment and postdevelopment activities should be The individual supplier level clearly differentiated: The level of the individual buyer The departmental level Purchasing's involvement in the predevelopment stage The overall company level, when purchasing's contri- of new products or projects - purchasing should be bution to the company's financial results is being involved in new product development projects in or- measured der to investigate at an early stage the extent to which purchased parts required for end products are avail- able in the market. Early involvement of purchasing ESTABLISHING A PURCHASING PERFORMANCE should also result in suggestions for product, materials, EVALUATION SYSTEM and/or design alternatives. The following basic guidelines should be utilized in Purchasing's involvement in the postdevelopment establishing a purchasing performance evaluation system. stage of new products or projects - it is purchasing's job to ensure that goods ordered are delivered ac- 1. The evaluation system should be designed in a cording to specifications. manner that corresponds with the daily operations of the buyer involved. As noted earlier in the article, the Purchasing Logistics Dimension system should provide information that can contribute A third key performance area is purchasing's responsibility to better decision making by the buyer. for an efficient incoming flow of purchased materials and 2. The buyer needs to participate in the establishment of services. This area includes the following major activities: standards for his or her activities; further, the buyer 1. Control of the timely flow of accurate requisitions should be involved in determining the devices that are and bills of material. used to monitor variances between actual and planned 2. Control of timely delivery by suppliers. performance outcomes. 3. Control of quantities delivered. 3. To maximize the practical value of the system, 4. In some cases, purchasing has the responsibility for performance feedback should be provided to the determination and control of cost effective inventory buyer on a timely basis so this information can be levels. used in taking corrective action when necessary. Obviously, the information should be provided in a Purchasing's Organization Dimension manner tailored to fit the individual buyer's need. This dimension includes the major resources that are used 4. Standards for evaluative purposes should be set only to achieve the goals and objectives of the purchasing in those areas for which the buyer can legitimately be function -- namely: held responsible; if uncontrollable external influences are significant, evaluation of the resulting perform- 1. Purchasing operating personnel. ance clearly has little meaning. 2. Purchasing management personnel. 3. Purchasing procedures and guidelines. Although performance standards are sometimes difficult 4. Purchasing's support resources - e.g., information to establish with accuracy, the job usually can be done systems, research, etc. acceptably if one perseveres. The more common methods of establishing performance standards are: (1) by use of Figure 3 provides an overview of the key areas of expert opinion based on studies and experience, (2) through purchasing performance evaluation. A comprehensive time series analysis when dealing with data that lends itself assessment should focus on each of these areas, individually to such analysis, (3) by means of intercompany and and collectively interindustry comparisons, and (4) through the use of Operationally speaking, it is clear that interrelationships estimates and subjective judgment. In addition, certain exist among all four dimensions. For example, if purchasing activities can be measured over a period of time and pushes hard for lower prices, this action may ultimately analyzed to see if acceptable performance standards can be