Question: What is the issue with the current plan. What can they do to improve it? B antuais Ken Mack, planer for the Company was having

What is the issue with the current plan. What can they do to improve it?

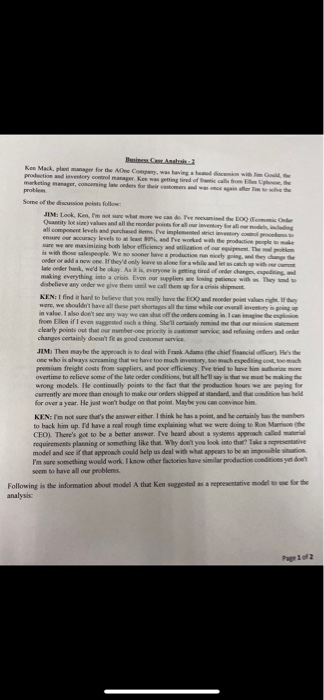

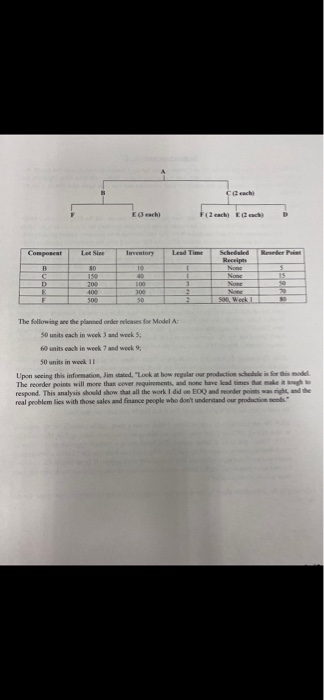

B antuais Ken Mack, planer for the Company was having med product and investory manager was going of marketing manager, concorsing wonders for the customers and problem al l whethe JIM: Lock, Kenmore what we can det Quantity o v es and all the order for all our very for all component levels and purchased in impleme nt en sy levels to clean and word with the productie ware wewe maximining boshlabor efficiency and will do the is with the salespeople. We now have a production niya and beyo te onder or add a new one they only leaves for a while w e cach latender bank, weld be okay. As it is veryone is ng tired of onder dage n making everything into a crisis Even our suppliers wengine with They disbelieve an order we give them wil we call them up for a cris e KEN: find it hard to believe that you really have the B and onderpoint they were, we wouldn't have all these part short all the time while our ow in value o don't wy way we can shut off the coming incom e from Ellenir leven gested such a thing shell cry remind me that w e clearly points out that our number one price is s e rvice and refusing clienda changes certainly doesn't fit as good s ervice JIM Then may be the approach is to deal with Prank Adams the chief facial offer Hesthe one who is always screaming that we have too much m ory.too much expedicos premium freight costs from suppliers, and poor efficiency. The tried to have him wh e re overtime to relieve some of the late onder conditions, but all he'lly is that we cheming the wrong models. He continually points to the fact that the production hours we are paying for Currently are more than enough to make our orders shipped at standard, and that condition e d for over a year. He just won't budge on that point. Maybe you can convince him KEN: I'm not sure that's the answer either. I think he has a point and the c ity has the sumber to hack him up. Td have a real rough time explaining what we were doing to Rose Marische CEO). There's got to be a better answer. I've heard about a systems approached requirement planning or something like that. Why don't you look into th e model and see if that approach could help us deal with what appears to be o s yet I'm sure something would work. I know other factories have similar productiv seem to have all our problems. Following is the information about model that Ken se posted as a representative models we for the analysis Page 1 of 2 The following the planned order releases for Model A 50 units each in week and week 5: 60 nits each in week and week 50 units in work II Upon in this information, Jim stad. "Look how regular our production schedule The reader points will more than cover requirements and to have lead times respond. This analysis should show that all the work I did and onder real problem lies with those sales and finance people who don't understand our product d d e B antuais Ken Mack, planer for the Company was having med product and investory manager was going of marketing manager, concorsing wonders for the customers and problem al l whethe JIM: Lock, Kenmore what we can det Quantity o v es and all the order for all our very for all component levels and purchased in impleme nt en sy levels to clean and word with the productie ware wewe maximining boshlabor efficiency and will do the is with the salespeople. We now have a production niya and beyo te onder or add a new one they only leaves for a while w e cach latender bank, weld be okay. As it is veryone is ng tired of onder dage n making everything into a crisis Even our suppliers wengine with They disbelieve an order we give them wil we call them up for a cris e KEN: find it hard to believe that you really have the B and onderpoint they were, we wouldn't have all these part short all the time while our ow in value o don't wy way we can shut off the coming incom e from Ellenir leven gested such a thing shell cry remind me that w e clearly points out that our number one price is s e rvice and refusing clienda changes certainly doesn't fit as good s ervice JIM Then may be the approach is to deal with Prank Adams the chief facial offer Hesthe one who is always screaming that we have too much m ory.too much expedicos premium freight costs from suppliers, and poor efficiency. The tried to have him wh e re overtime to relieve some of the late onder conditions, but all he'lly is that we cheming the wrong models. He continually points to the fact that the production hours we are paying for Currently are more than enough to make our orders shipped at standard, and that condition e d for over a year. He just won't budge on that point. Maybe you can convince him KEN: I'm not sure that's the answer either. I think he has a point and the c ity has the sumber to hack him up. Td have a real rough time explaining what we were doing to Rose Marische CEO). There's got to be a better answer. I've heard about a systems approached requirement planning or something like that. Why don't you look into th e model and see if that approach could help us deal with what appears to be o s yet I'm sure something would work. I know other factories have similar productiv seem to have all our problems. Following is the information about model that Ken se posted as a representative models we for the analysis Page 1 of 2 The following the planned order releases for Model A 50 units each in week and week 5: 60 nits each in week and week 50 units in work II Upon in this information, Jim stad. "Look how regular our production schedule The reader points will more than cover requirements and to have lead times respond. This analysis should show that all the work I did and onder real problem lies with those sales and finance people who don't understand our product d d e