Question: Which alternative would be selected, and how many machines, in order to minimize total cost while satisfying capacity processing requirements? 12. A manager must decide

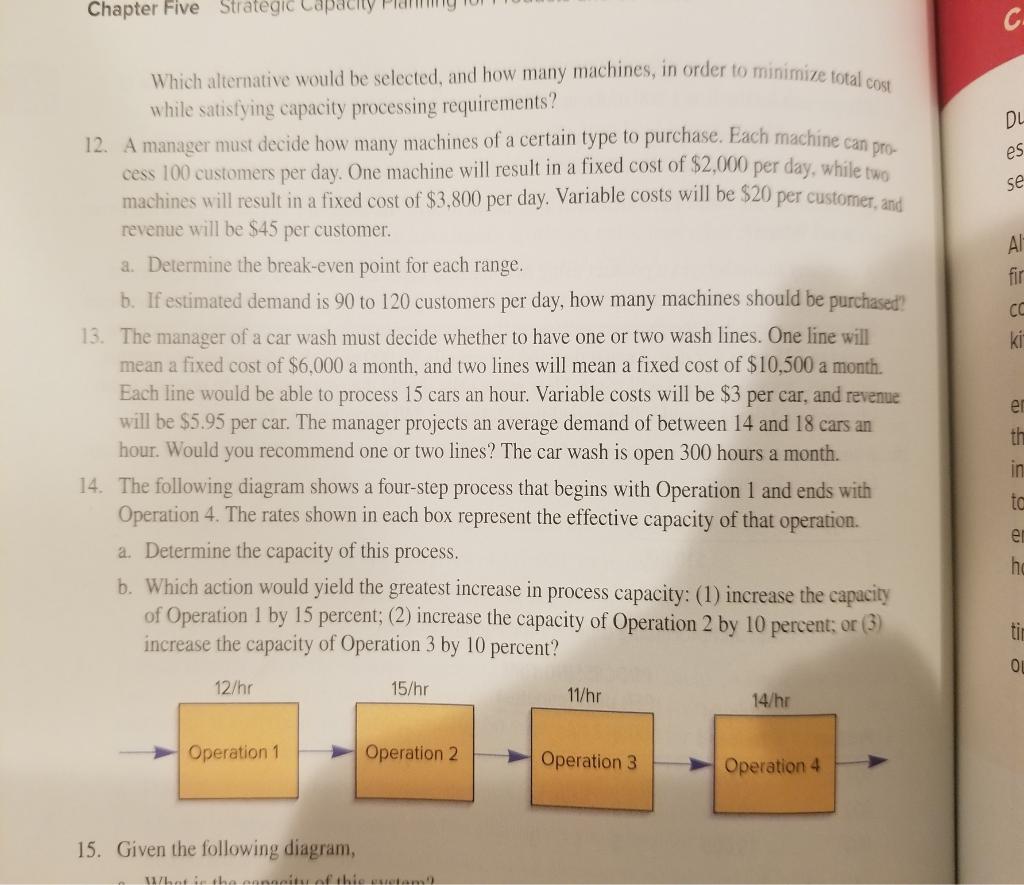

Which alternative would be selected, and how many machines, in order to minimize total cost while satisfying capacity processing requirements? 12. A manager must decide how many machines of a certain type to purchase. Each machine can process 100 customers per day. One machine will result in a fixed cost of $2,000 per day, while two machines will result in a fixed cost of $3,800 per day. Variable costs will be $20 per customer, and revenue will be $45 per customer. a. Determine the break-even point for each range. b. If estimated demand is 90 to 120 customers per day, how many machines should be purchased? 13. The manager of a car wash must decide whether to have one or two wash lines. One line will mean a fixed cost of $6,000 a month, and two lines will mean a fixed cost of $10,500 a month. Each line would be able to process 15 cars an hour. Variable costs will be $3 per car, and revenue will be $5.95 per car. The manager projects an average demand of between 14 and 18 cars an hour. Would you recommend one or two lines? The car wash is open 300 hours a month. 14. The following diagram shows a four-step process that begins with Operation 1 and ends with Operation 4. The rates shown in each box represent the effective capacity of that operation. a. Determine the capacity of this process. b. Which action would yield the greatest increase in process capacity: (1) increase the capacity of Operation 1 by 15 percent; (2) increase the capacity of Operation 2 by 10 percent; or (3) increase the capacity of Operation 3 by 10 percent? 15. Given the following diagram, 1. Determine the utilization and the efliciency for each of these situations. a. A hoan processing operation that processes an average of 7 loans per day. The operation has a design capacity of 10 loans per day and an effective capacity of 8 loans per day. b. A furmace repair team that services an average of four furnaces a day if the design capacity is six furnaces a day and the effective capacity is five furnaces a day. c. Would you say that systems that have higher efficiency ratios than other systems will aloays. have higher utilization ratios than those other systems? Explain. 2. In a job shop, effective capacity is only 50 percent of design capacity. and actual output is \&n percent of effective output. What design capacity would be needed to achieve an actral output of eight jobs per week? 3. A producer of pottery is considering the addition of a new plant to absorb the backlog of demand that now exists. The primary location being considered will have fixed costs of $9,200 per month and vari. able costs of 70 cents per unit produced. Each item is sold to retailers at a price that averages 90 cents. a. What volume per month is required in order to break even? b. What profit would be realized on a monthly volume of 61,000 units? 87,000 units? c. What volume is needed to obtain a profit of $16,000 per month? d. What volume is needed to provide a revenue of $23,000 per month? e. Plot the total cost and total revenue lines. 4. A small firm intends to increase the capacity of a bottleneck operation by adding a new machine. Two alternatives, A and B, have been identified, and the associated costs and revenues have been estimated. Annual fixed costs would be $40,000 for A and $30,000 for B; variable costs per unit would be $10 for A and $11 for B; and revenue per unit would be $15. a. Determine each alternative's break-even point in units. b. At what volume of output would the two alternatives yield the same profit? c. If expected annual demand is 12,000 units, which alternative would yield the higher profit? 5. A producer of felt-tip pens has received a forecast of demand of 30,000 pens for the coming month from its marketing department. Fixed coste of $25nn

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts