Question: Which tool helps to categorise risks into three colour-coded zones representing major, moderate, and minor risks Failure Mode and Effects Analysis Rlsk Priority Number Risk

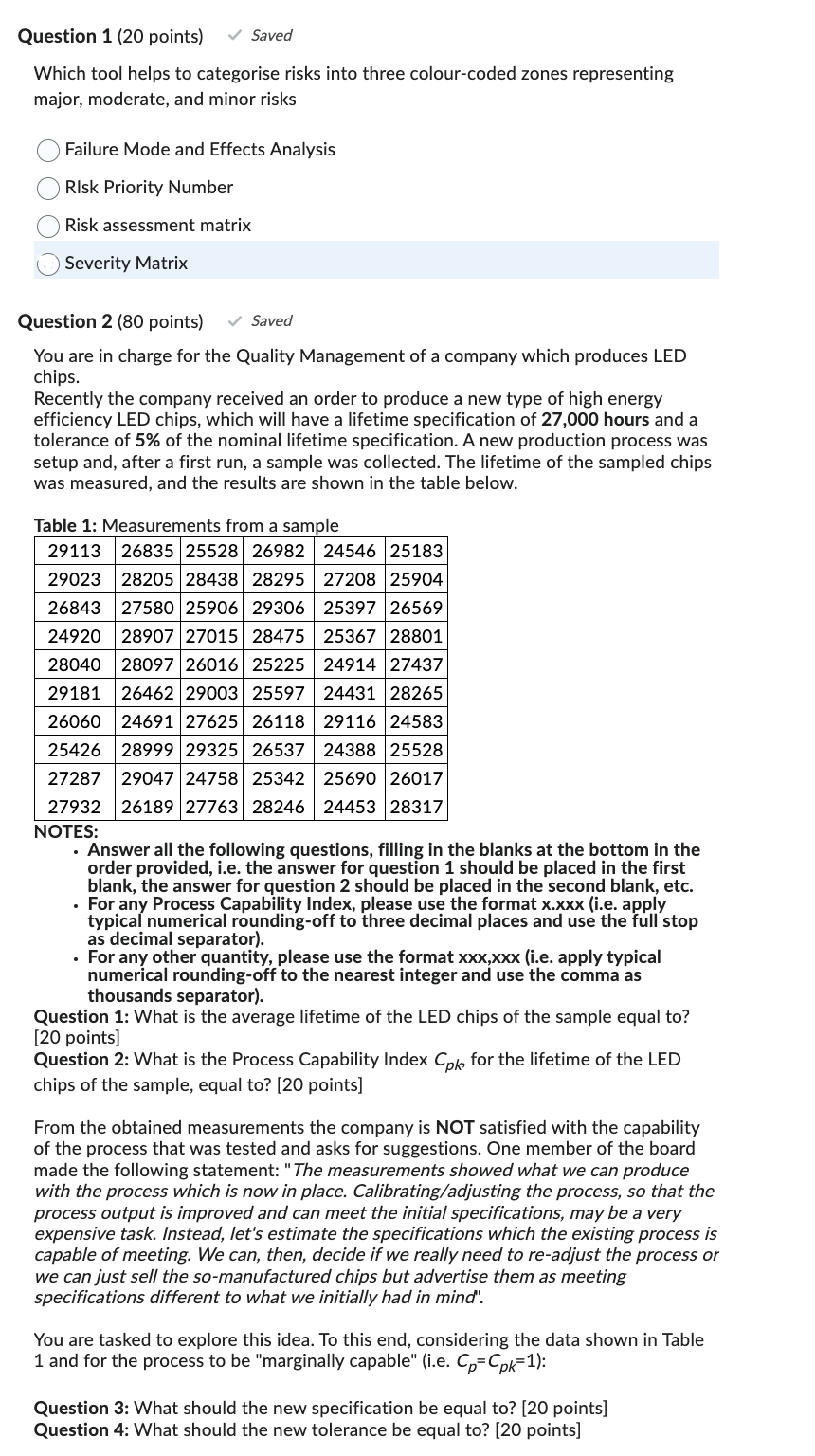

Which tool helps to categorise risks into three colour-coded zones representing major, moderate, and minor risks Failure Mode and Effects Analysis Rlsk Priority Number Risk assessment matrix Severity Matrix Question 2 (80 points) Saved You are in charge for the Quality Management of a company which produces LED chips. Recently the company received an order to produce a new type of high energy efficiency LED chips, which will have a lifetime specification of 27,000 hours and a tolerance of 5% of the nominal lifetime specification. A new production process was setup and, after a first run, a sample was collected. The lifetime of the sampled chips was measured, and the results are shown in the table below. IVUIID: - Answer all the following questions, filling in the blanks at the bottom in the order provided, i.e. the answer for question 1 should be placed in the first blank, the answer for question 2 should be placed in the second blank, etc. - For any Process Capability Index, please use the format x.xxx (i.e. apply typical numerical rounding-off to three decimal places and use the full stop as decimal separator). - For any other quantity, please use the format xxx,xxx (i.e. apply typical numerical rounding-off to the nearest integer and use the comma as thousands separator). Question 1: What is the average lifetime of the LED chips of the sample equal to? [20 points] Question 2: What is the Process Capability Index Cpk, for the lifetime of the LED chips of the sample, equal to? [ 20 points] From the obtained measurements the company is NOT satisfied with the capability of the process that was tested and asks for suggestions. One member of the board made the following statement: "The measurements showed what we can produce with the process which is now in place. Calibrating/adjusting the process, so that the process output is improved and can meet the initial specifications, may be a very expensive task. Instead, let's estimate the specifications which the existing process is capable of meeting. We can, then, decide if we really need to re-adjust the process or we can just sell the so-manufactured chips but advertise them as meeting specifications different to what we initially had in mind". You are tasked to explore this idea. To this end, considering the data shown in Table 1 and for the process to be "marginally capable" (i.e. Cp=Cpk=1 ): Question 3: What should the new specification be equal to? [ 20 points] Question 4: What should the new tolerance be equal to? [ 20 points]