Question: WORK BREAKDOWN STRUCTURE PART 2 CASE STUDY 2.2 Automated Interdiction System (AIS) Workstation Project The project control manager, Karen, began to think about observing the

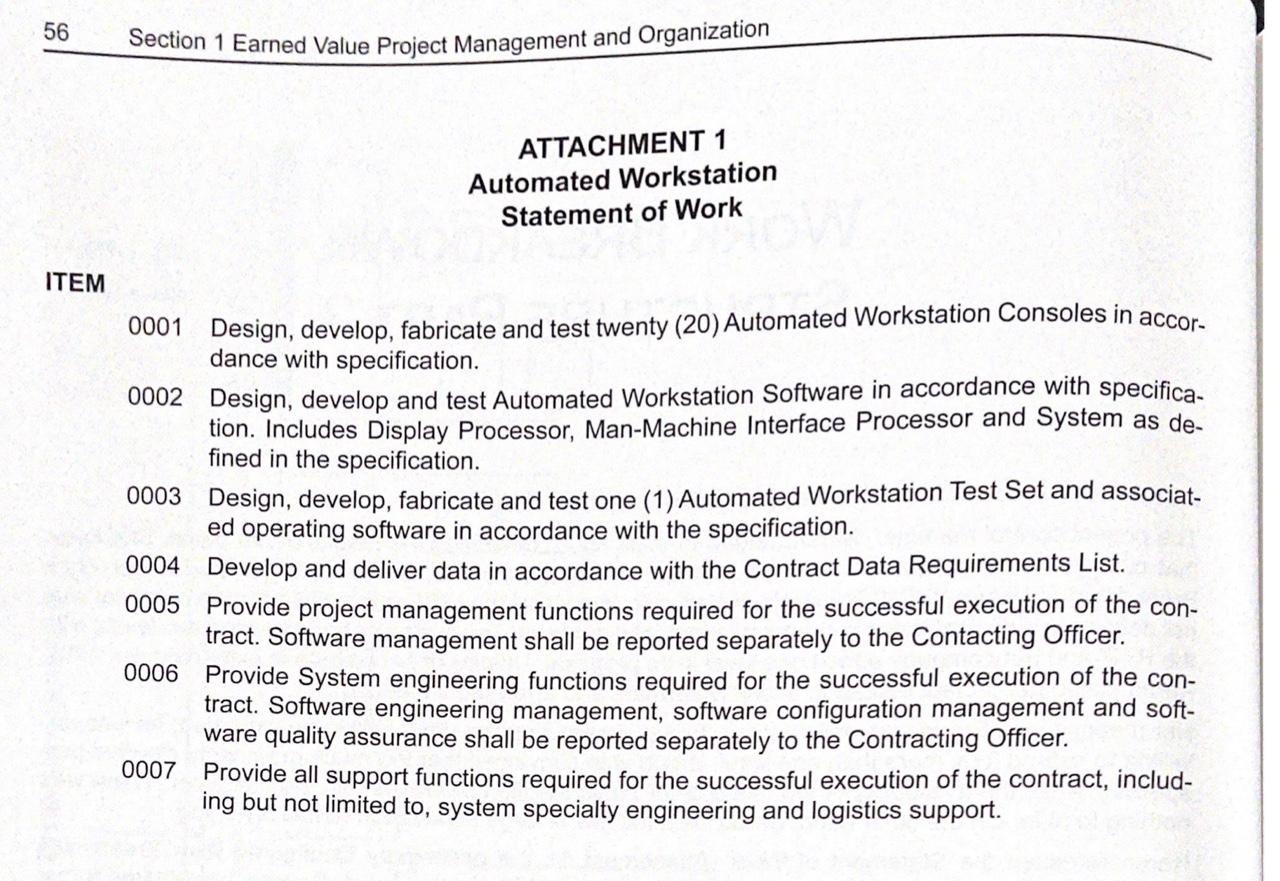

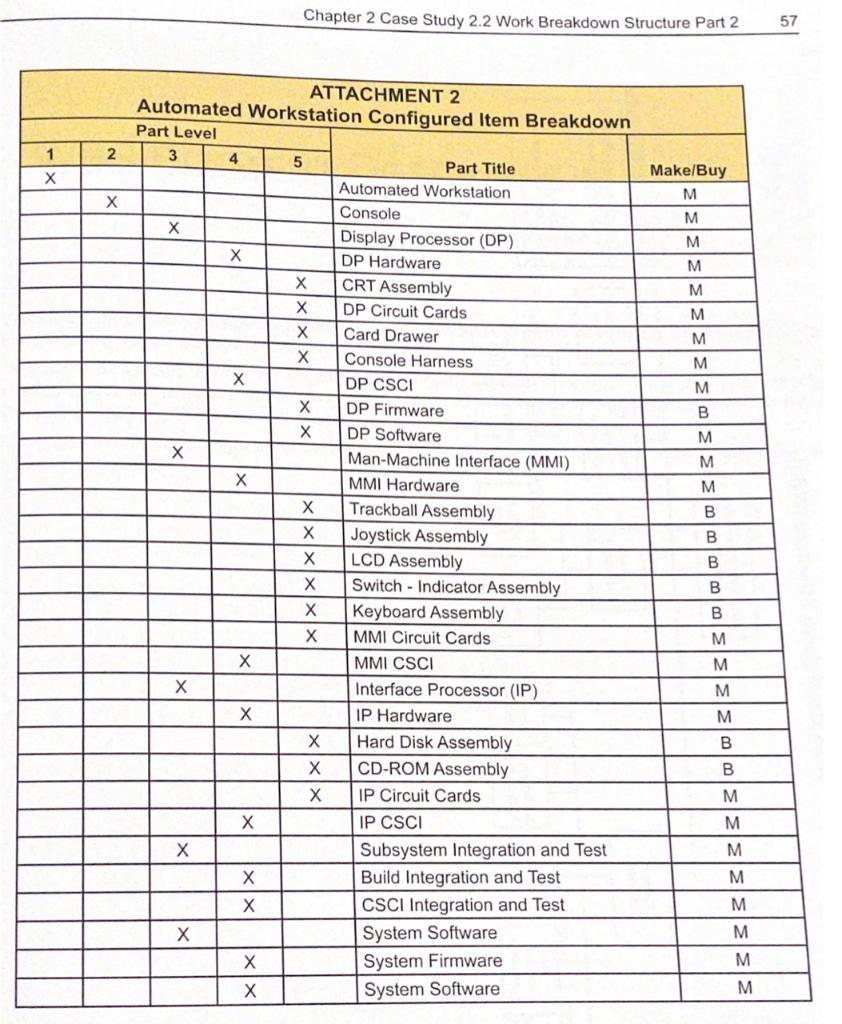

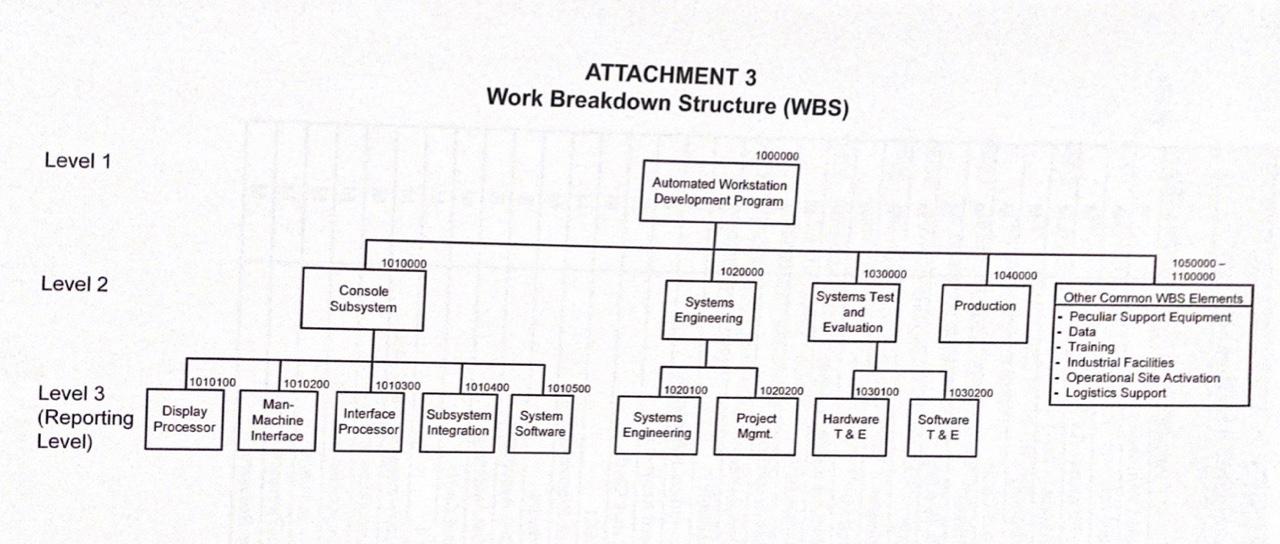

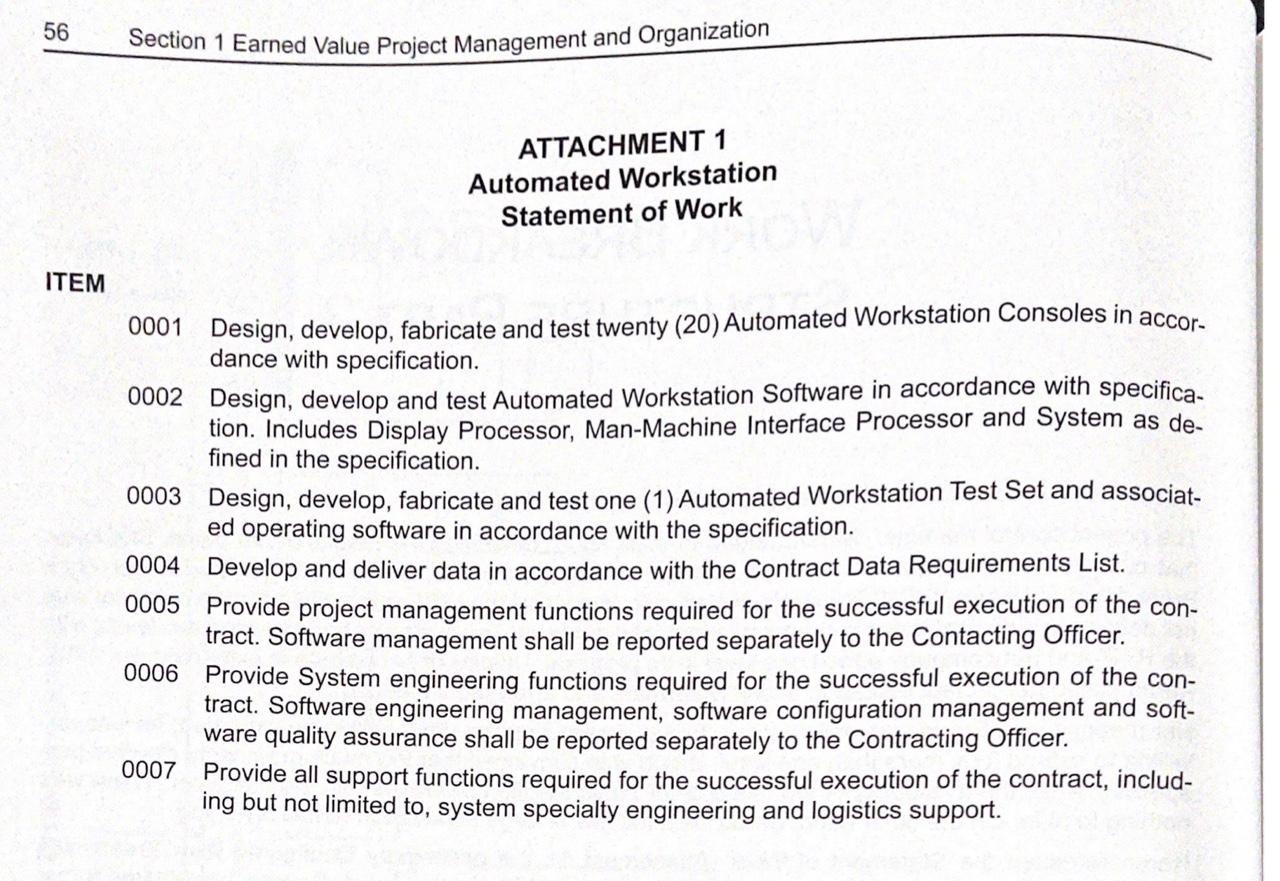

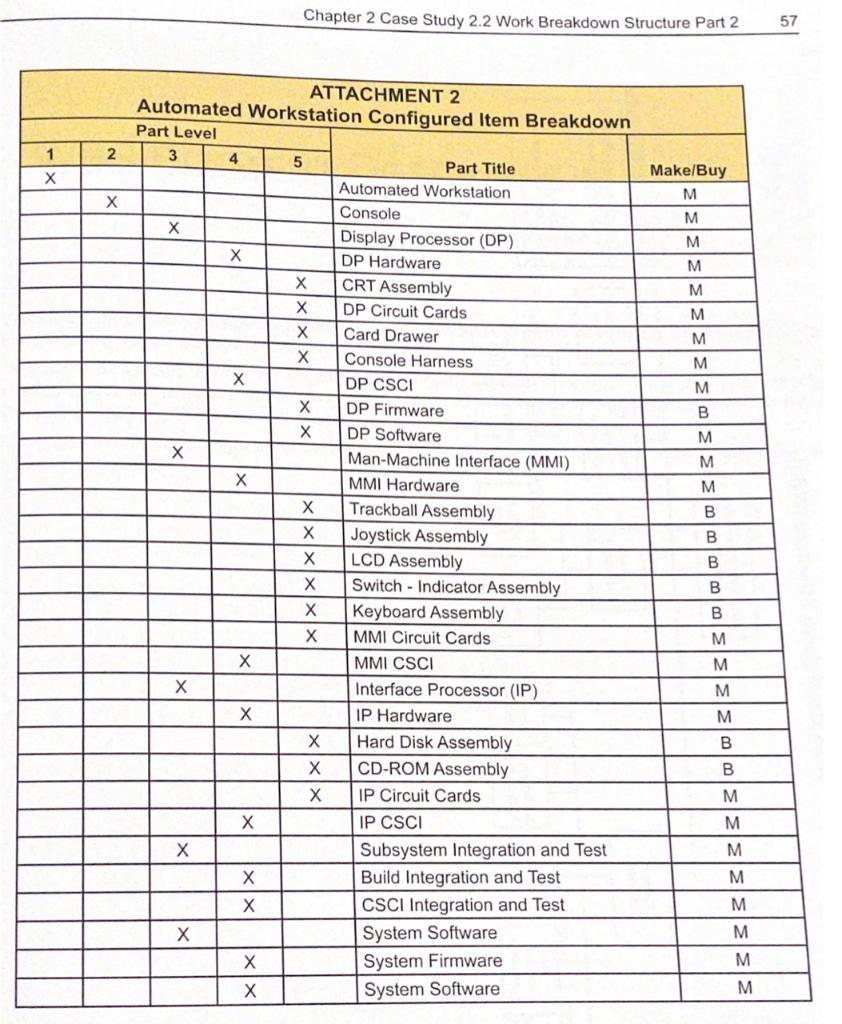

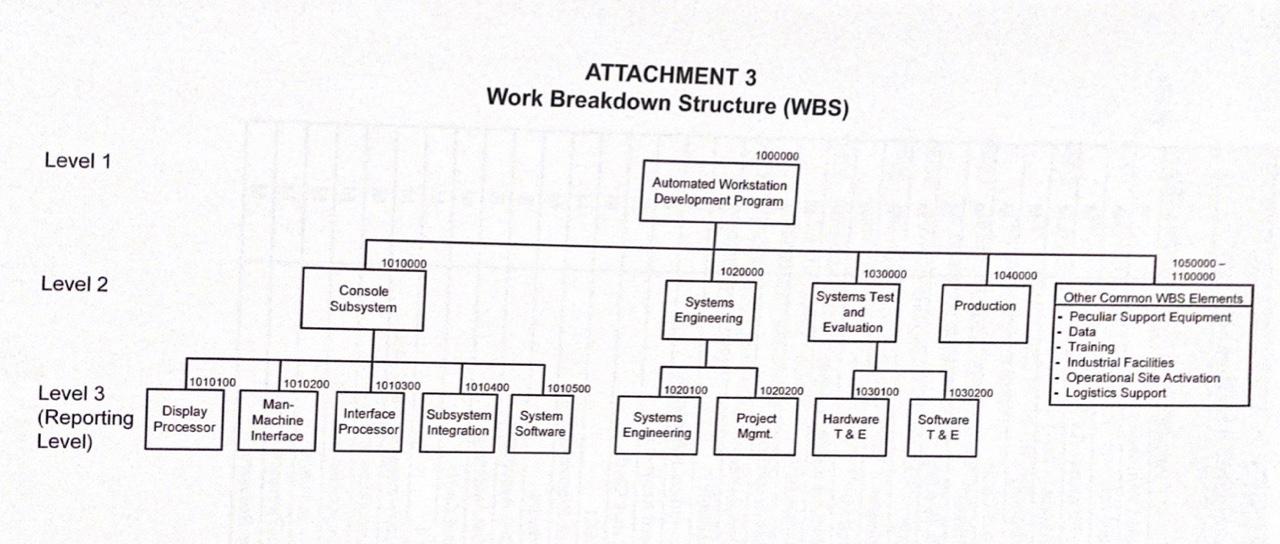

WORK BREAKDOWN STRUCTURE PART 2 CASE STUDY 2.2 Automated Interdiction System (AIS) Workstation Project The project control manager, Karen, began to think about observing the results of her plans. She knew that cost data was collected by control account and that control accounts were grouped under Work Breakdown Structure (WBS) elements. Karen also knew that the WBS submitted with the proposal was not defined in sufficient detail to permit a meaningful analysis. The customer had provided two levels with the RFP, and her company added one level in its proposal. Unsure of her latitude in extending the WBS, Karen called her project manager, Broud Stearman, and arranged a meeting. Her meeting with Broud was enlightening. Broud agreed that the WBS had to be extended; he was un- willing to extend it by more than one level. Broud was convinced that too much granularity clouded per- spective. Also, the availability of too much detail could result in problems with the customer. There was nothing to hide. On the other hand, Broud liked the law of large numbers in formal reporting. Karen retrieved the Statement of Work (Attachment 1), the preliminary Configured Item Breakdown (Attachment 2), and the WBS (Attachment 3) submitted with the proposal. Several hours later Broud walked into Karen's office and offered to help with the extension - he also had a stake in the outcome of her work. Unfortunately, Broud was unfamiliar with software development activities. Using the SOW, the preliminary Configured Item Breakdown and the preliminary WBS: 1. Expand the WBS to provide better visibility of progress. 2. Do you agree with Broud that the WBS should be extended by only one level? 3. How should multiple builds be handled? 56 Section 1 Earned Value Project Management and Organization ATTACHMENT 1 Automated Workstation Statement of Work ITEM 0001 Design, develop, fabricate and test twenty (20) Automated Workstation Consoles in accor- dance with specification. 0002 Design, develop and test Automated Workstation Software in accordance with specifica- tion. Includes Display Processor, Man-Machine Interface Processor and System as de fined in the specification. 0003 Design, develop, fabricate and test one (1) Automated Workstation Test Set and associat- ed operating software in accordance with the specification. 0004 Develop and deliver data in accordance with the Contract Data Requirements List. 0005 Provide project management functions required for the successful execution of the con- tract. Software management shall be reported separately to the Contacting Officer. 0006 Provide System engineering functions required for the successful execution of the con- tract. Software engineering management, software configuration management and soft- ware quality assurance shall be reported separately to the Contracting Officer. 0007 Provide all support functions required for the successful execution of the contract, includ- ing but not limited to, system specialty engineering and logistics support. Chapter 2 Case Study 2.2 Work Breakdown Structure Part 2 57 ATTACHMENT 2 Automated Workstation Configured Item Breakdown Part Level 1 2 3 4 5 Part Title Make/Buy Automated Workstation M M M Console Display Processor (DP) DP Hardware CRT Assembly DP Circuit Cards M M xxxx M Card Drawer M Console Harness M X DP CSCI M DP Firmware B x x DP Software M M M B B Man-Machine Interface (MMI) MMI Hardware Trackball Assembly Joystick Assembly LCD Assembly Switch - Indicator Assembly Keyboard Assembly MMI Circuit Cards B xxxxxx B B M MMI CSCI M X Interface Processor (IP) M IP Hardware M X B Hard Disk Assembly CD-ROM Assembly X B IP Circuit Cards M IP CSCI M M M x x M Subsystem Integration and Test Build Integration and Test CSCI Integration and Test System Software System Firmware System Software M M M ATTACHMENT 3 Work Breakdown Structure (WBS) Level 1 1000000 Automated Workstation Development Program 1010000 1020000 1030000 1050000 - 1100000 1040000 Level 2 Console Subsystem Systems Engineering Systems Test and Evaluation Production Other Common WBS Elements Peculiar Support Equipment Data Training Industrial Facilities Operational Site Activation Logistics Support 1010100 1010300 1010400 1010500 1020100 1020200 1030100 1030200 Level 3 (Reporting Level) Display Processor 1010200 Man- Machine Interface Interface Processor Subsystem Integration System Software Systems Engineering Project Mgmt. Hardware T&E Software T&E WORK BREAKDOWN STRUCTURE PART 2 CASE STUDY 2.2 Automated Interdiction System (AIS) Workstation Project The project control manager, Karen, began to think about observing the results of her plans. She knew that cost data was collected by control account and that control accounts were grouped under Work Breakdown Structure (WBS) elements. Karen also knew that the WBS submitted with the proposal was not defined in sufficient detail to permit a meaningful analysis. The customer had provided two levels with the RFP, and her company added one level in its proposal. Unsure of her latitude in extending the WBS, Karen called her project manager, Broud Stearman, and arranged a meeting. Her meeting with Broud was enlightening. Broud agreed that the WBS had to be extended; he was un- willing to extend it by more than one level. Broud was convinced that too much granularity clouded per- spective. Also, the availability of too much detail could result in problems with the customer. There was nothing to hide. On the other hand, Broud liked the law of large numbers in formal reporting. Karen retrieved the Statement of Work (Attachment 1), the preliminary Configured Item Breakdown (Attachment 2), and the WBS (Attachment 3) submitted with the proposal. Several hours later Broud walked into Karen's office and offered to help with the extension - he also had a stake in the outcome of her work. Unfortunately, Broud was unfamiliar with software development activities. Using the SOW, the preliminary Configured Item Breakdown and the preliminary WBS: 1. Expand the WBS to provide better visibility of progress. 2. Do you agree with Broud that the WBS should be extended by only one level? 3. How should multiple builds be handled? 56 Section 1 Earned Value Project Management and Organization ATTACHMENT 1 Automated Workstation Statement of Work ITEM 0001 Design, develop, fabricate and test twenty (20) Automated Workstation Consoles in accor- dance with specification. 0002 Design, develop and test Automated Workstation Software in accordance with specifica- tion. Includes Display Processor, Man-Machine Interface Processor and System as de fined in the specification. 0003 Design, develop, fabricate and test one (1) Automated Workstation Test Set and associat- ed operating software in accordance with the specification. 0004 Develop and deliver data in accordance with the Contract Data Requirements List. 0005 Provide project management functions required for the successful execution of the con- tract. Software management shall be reported separately to the Contacting Officer. 0006 Provide System engineering functions required for the successful execution of the con- tract. Software engineering management, software configuration management and soft- ware quality assurance shall be reported separately to the Contracting Officer. 0007 Provide all support functions required for the successful execution of the contract, includ- ing but not limited to, system specialty engineering and logistics support. Chapter 2 Case Study 2.2 Work Breakdown Structure Part 2 57 ATTACHMENT 2 Automated Workstation Configured Item Breakdown Part Level 1 2 3 4 5 Part Title Make/Buy Automated Workstation M M M Console Display Processor (DP) DP Hardware CRT Assembly DP Circuit Cards M M xxxx M Card Drawer M Console Harness M X DP CSCI M DP Firmware B x x DP Software M M M B B Man-Machine Interface (MMI) MMI Hardware Trackball Assembly Joystick Assembly LCD Assembly Switch - Indicator Assembly Keyboard Assembly MMI Circuit Cards B xxxxxx B B M MMI CSCI M X Interface Processor (IP) M IP Hardware M X B Hard Disk Assembly CD-ROM Assembly X B IP Circuit Cards M IP CSCI M M M x x M Subsystem Integration and Test Build Integration and Test CSCI Integration and Test System Software System Firmware System Software M M M ATTACHMENT 3 Work Breakdown Structure (WBS) Level 1 1000000 Automated Workstation Development Program 1010000 1020000 1030000 1050000 - 1100000 1040000 Level 2 Console Subsystem Systems Engineering Systems Test and Evaluation Production Other Common WBS Elements Peculiar Support Equipment Data Training Industrial Facilities Operational Site Activation Logistics Support 1010100 1010300 1010400 1010500 1020100 1020200 1030100 1030200 Level 3 (Reporting Level) Display Processor 1010200 Man- Machine Interface Interface Processor Subsystem Integration System Software Systems Engineering Project Mgmt. Hardware T&E Software T&E