Question: Work Time: 20 days in a month three shift continuous operation in all production departments work hours: 6am Monday to 10pm Friday 8 hours every

Work Time:

20 days in a month

three shift continuous operation in all production departments

work hours: 6am Monday to 10pm Friday

8 hours every shift, with overtime if necessary

Two 10-minute breaks during each shift and 1hour Lunch. (processes stop at these times)

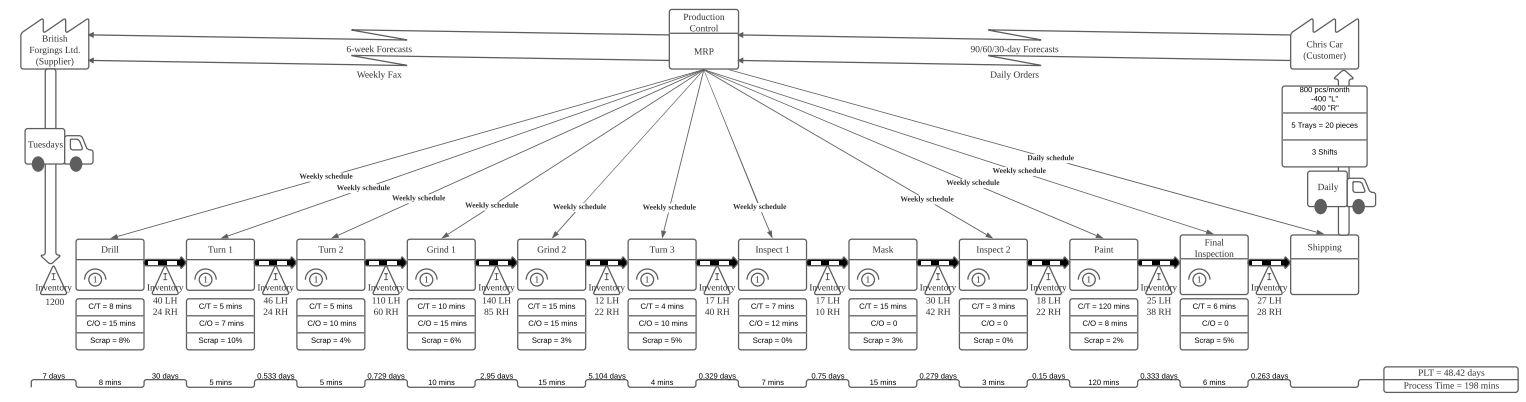

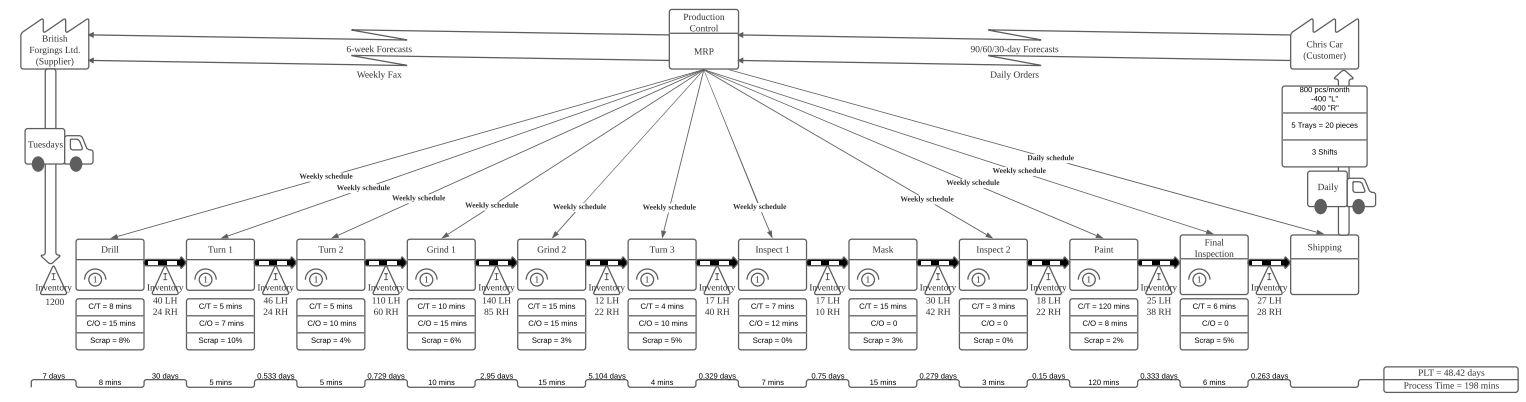

Before: Customer requests 800 pieces per month, 400 LH and 400 RH

Customer now wants to request 1600 pieces, or double the previous order amount.

Below shows current value stream map. Please state the 3 types of wastes and make a future stream map to reduce these wastes.

***(Right click the image and open in new tab for better image view)

Production Control British Forgings Ltd. (Supplier) 6-week Forecasts MRP 90/60/30-day Forecasts Chris Car (Customer) Weekly Fax Daily Orders BoU pcs month -400 "L" -400 "R R 5 Trays - 20 preces Tuesdays 3 Shifts Daily schedule Weekly schedule Weekly schedule Weekly schedule Weekly schedule Weekly schedule Daily Weekly schedule Weekly schedule Weekly schedule Weekly schedule Weekly schedule Drill Turn 1 Turn 2 Grind 1 Grind 2 Tum3 Inspect 1 Mask Inspect 2 Paint Final Inspection Shipping CC OT o Inventory 1200 / Menty 40 LH 24 RH Inventdy 46 LH 24 RH Topenty 110 LH 60 RH Inventory 140 LH 85 RH Inventory 12 LH 22 RH Wenty 17 LH 40 RH DC /1 Inventory 17 LH 10 RH Twenty 30 LH 42 RH Inventory 18 LH 22 RH Inventory 25 LH 38 RH Trendy 27 LH 28 RH CT = 5 mins CIT = 15 mins CIT = 7 mins CIT 120 mins CIT = 15 mins CIT = 3 ming CAT = 8 mins C/O = 15 mins CIT = 5 mins C/O = 7 mins Scrap = 1094 C/T = 10 mins C/O = 15 mins C/T = 4 mins CIO = 10 mins C/T = 6 mins C/O=0 CIO = 10 mins = CIO = 15 mins CIO = 12 mins C/O = 0 CIO = min CIO = 0 Scrap 396 Scrap = 896 Scrap a 49 Scrap = 0% Scrap 3% Scrap 54 Scrap = 0 Scrap = 0% Scrap 29 Scrap = 546 7 days 30 de 0.533.des 0.729 dans 2495 days 5.104 dars 0.329 days 0.279 dans 8 mins 0.333.devs 0.75 ders days 5 mins 5 mins 0.15 days 10 mins 4 mins 15 mins 7 mins 15 mins 3 mins 120 mins 9.263 days 6 mins PLT = 48,42 days Process Time - 198 mins Production Control British Forgings Ltd. (Supplier) 6-week Forecasts MRP 90/60/30-day Forecasts Chris Car (Customer) Weekly Fax Daily Orders BoU pcs month -400 "L" -400 "R R 5 Trays - 20 preces Tuesdays 3 Shifts Daily schedule Weekly schedule Weekly schedule Weekly schedule Weekly schedule Weekly schedule Daily Weekly schedule Weekly schedule Weekly schedule Weekly schedule Weekly schedule Drill Turn 1 Turn 2 Grind 1 Grind 2 Tum3 Inspect 1 Mask Inspect 2 Paint Final Inspection Shipping CC OT o Inventory 1200 / Menty 40 LH 24 RH Inventdy 46 LH 24 RH Topenty 110 LH 60 RH Inventory 140 LH 85 RH Inventory 12 LH 22 RH Wenty 17 LH 40 RH DC /1 Inventory 17 LH 10 RH Twenty 30 LH 42 RH Inventory 18 LH 22 RH Inventory 25 LH 38 RH Trendy 27 LH 28 RH CT = 5 mins CIT = 15 mins CIT = 7 mins CIT 120 mins CIT = 15 mins CIT = 3 ming CAT = 8 mins C/O = 15 mins CIT = 5 mins C/O = 7 mins Scrap = 1094 C/T = 10 mins C/O = 15 mins C/T = 4 mins CIO = 10 mins C/T = 6 mins C/O=0 CIO = 10 mins = CIO = 15 mins CIO = 12 mins C/O = 0 CIO = min CIO = 0 Scrap 396 Scrap = 896 Scrap a 49 Scrap = 0% Scrap 3% Scrap 54 Scrap = 0 Scrap = 0% Scrap 29 Scrap = 546 7 days 30 de 0.533.des 0.729 dans 2495 days 5.104 dars 0.329 days 0.279 dans 8 mins 0.333.devs 0.75 ders days 5 mins 5 mins 0.15 days 10 mins 4 mins 15 mins 7 mins 15 mins 3 mins 120 mins 9.263 days 6 mins PLT = 48,42 days Process Time - 198 mins