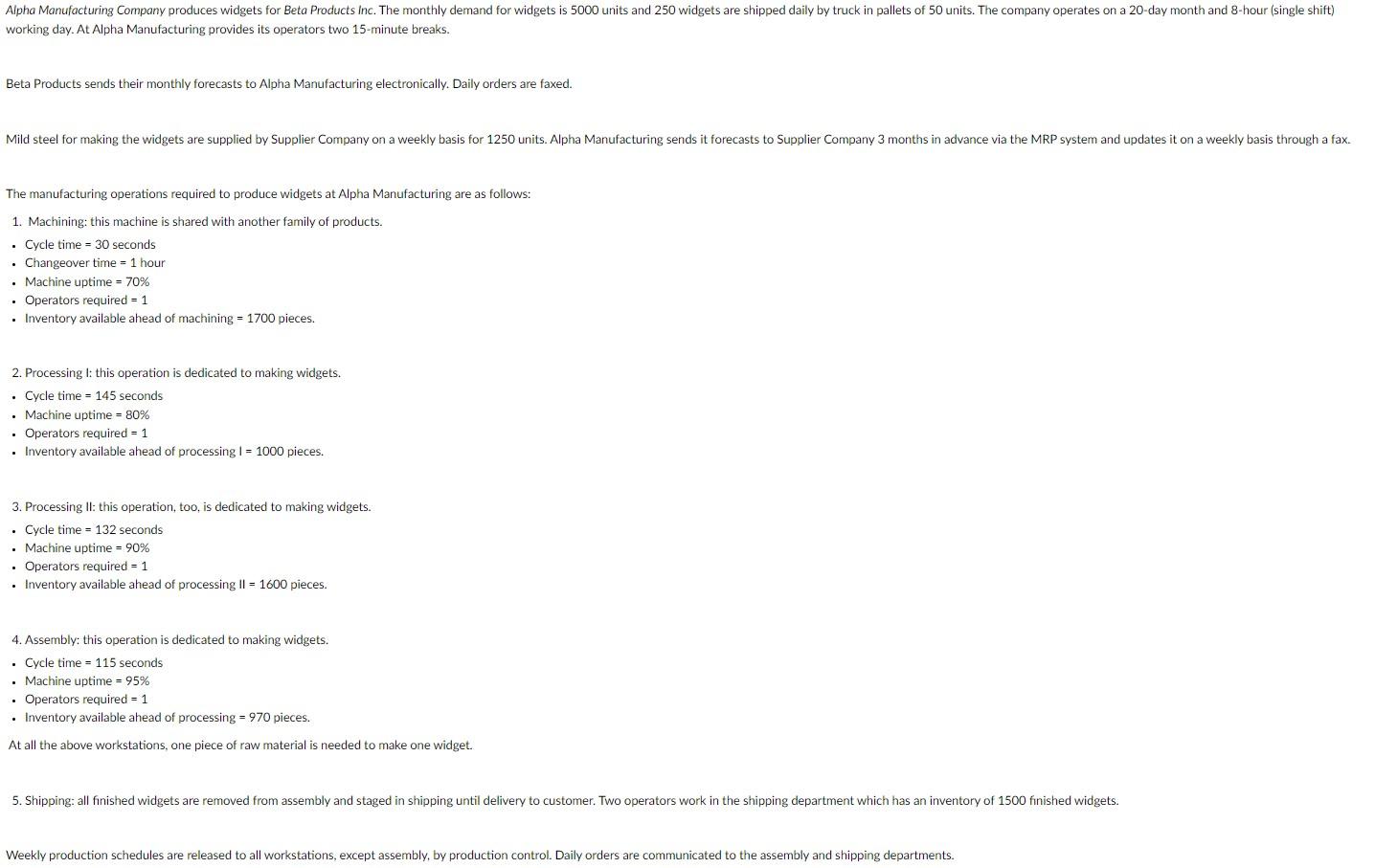

Question: working day. At Alpha Manufacturing provides its operators two 15-minute breaks. Beta Products sends their monthly forecasts to Alpha Manufacturing electronically. Daily orders are faxed.

working day. At Alpha Manufacturing provides its operators two 15-minute breaks. Beta Products sends their monthly forecasts to Alpha Manufacturing electronically. Daily orders are faxed. The manufacturing operations required to produce widgets at Alpha Manufacturing are as follows: 1. Machining: this machine is shared with another family of products. - Cycle time =30 seconds - Changeover time =1 hour - Machine uptime =70% - Operators required =1 - Inventory available ahead of machining =1700 pieces. 2. Processing l: this operation is dedicated to making widgets. - Cycle time =145 seconds - Machine uptime =80% - Operators required =1 - Inventory available ahead of processing =1000 pieces. 3. Processing II: this operation, too, is dedicated to making widgets. - Cycle time =132 seconds - Machine uptime =90% - Operators required = 1 - Inventory available ahead of processing II = 1600 pieces. 4. Assembly: this operation is dedicated to making widgets. - Cycle time =115 seconds - Machine uptime =95% - Operators required =1 - Inventory available ahead of processing =970 pieces. At all the above workstations, one piece of raw material is needed to make one widget. taken off for any missing information. Use the example discussed in the lecture video as the template for what information must be included (80 points). 2. Based on the Current State VSM, discuss your assessment of the process. - Are there any non-value adding activities/waste that are present? - Identify and describe the types of waste that can be readily observed. - Based on the information shown in the time line, comment on the process efficiency in terms of value added vs. non-value added activity times

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts