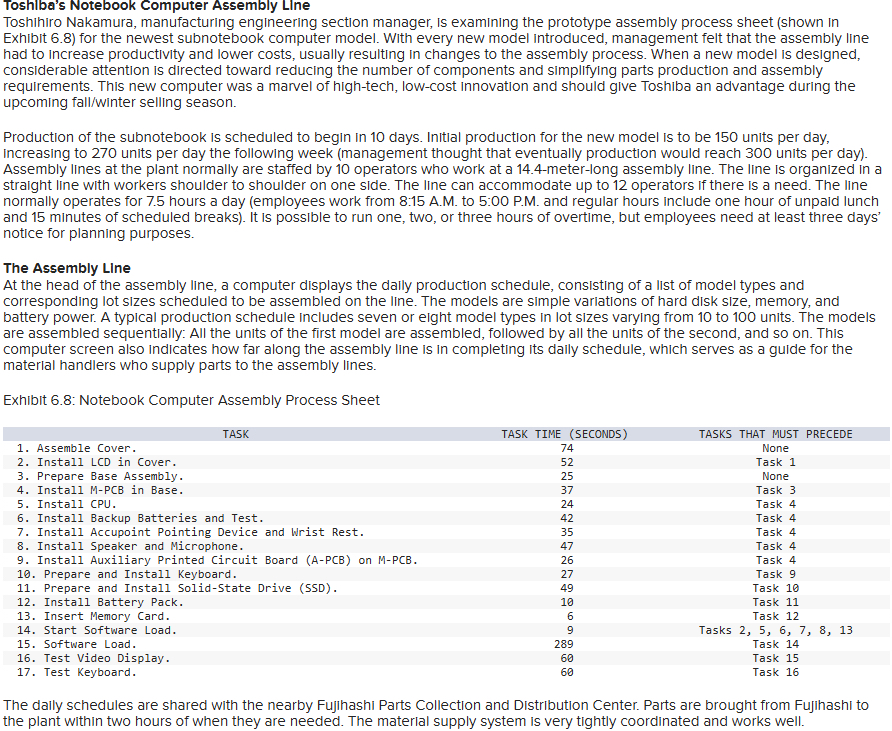

Question: Workstation 2 : The second operator performs two different tasks. First, the LCD screen is installed in the cover. This task needs to be done

Workstation : The second operator performs two different tasks. First, the LCD screen is installed in the cover. This task needs to be done after the cover is assembled task A second independent task done by the operator is the preparation of the base so that the Main Printed Circuit Board MPCB can be installed.

Workstation : Here the MPCB is installed in the base. After this is done, the Central Processing Unit CPU and backup batteries are installed and tested.

Workstation : The Accupoint Pointing Device touchpad and wrist rest are installed, the speaker and microphone is installed, and the Auxiliary Printed Circult Board APCB is installed. These are all independent tasks that can be done after the MPCB is installed.

Workstation : Here, tasks are performed in a sequence. First, the keyboard is installed, followed by the SolidState Drive SSD The battery pack is then installed, followed by the memory card. The computer is then powered up and a program started that loads software that can be used to test the computer. Actually loading the software takes seconds, and this is done while the computer travels through positions and on the assembly line. Computers that do not work are sent to a rework area where they are fixed. Only about percent of the computers fall to start, and these are usually quickly repaired by the supporter.

Workstation : The video display and keyboard are tested in this workstation.

After assembly, the computers are moved to a separate burnIn area that is separate from the assembly line. Here, computers are put in racks for a hour, "burn In of the circult components. After burnin the computer is tested again, software is installed, and the finished notebook computer is packaged and placed on pallets for shipment to Toshiba distribution centers around the world.

Tweaking the Initial AssemblyLIne Design

From past experience, Toshihiro has found that the initial assemblyline design supplied by the engineers often needs to be tweaked. Consider the following questions that Toshihiro is considering:

a If the assembly line is to be redesigned to operate at units per day without using overtime, what is the maximum cycle time to meet this production rate?

Note: Round down "maximum cycle time" values to the next smallest integer.

Cycle time

seconds per unit

b Develop an assembly line layout with the fewest possible assembly line positions and the fewest possible workstations with labor to produce units per day without using overtime. What is the efficiency of this new assembly line layout?

Note: Round your answer to decimal places.

Efficiency

Tweaking the Initlal AssemblyLIne Design

From past experience, Toshihiro has found that the initial assemblyline design supplied by the engineers often needs to be tweaked. Consider the following questions that Toshihiro is considering:

a If the assembly line is to be redesigned to operate at units per day without using overtime, what is the maximum cycle time to meet this production rate?

Note: Round down "maximum cycle time" values to the next smallest Integer.

Cycle time

seconds per unit

b Develop an assembly line layout with the fewest possible assembly line positions and the fewest possible workstations with labor to produce units per day without using overtime. What is the efficlency of this new assembly line layout?

Note: Round your answer to decimal places.

Efficiency

In your new layout, how many workstations include labor?

Number of workstations with labor

workstations.

Can this assembly line layout fit on the existing position conveyor belt system?

Yes

No

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock