Question: Would like help please with both pics. Use the process information provided in the following table, when the sequence of flow is A - B

Would like help please with both pics.

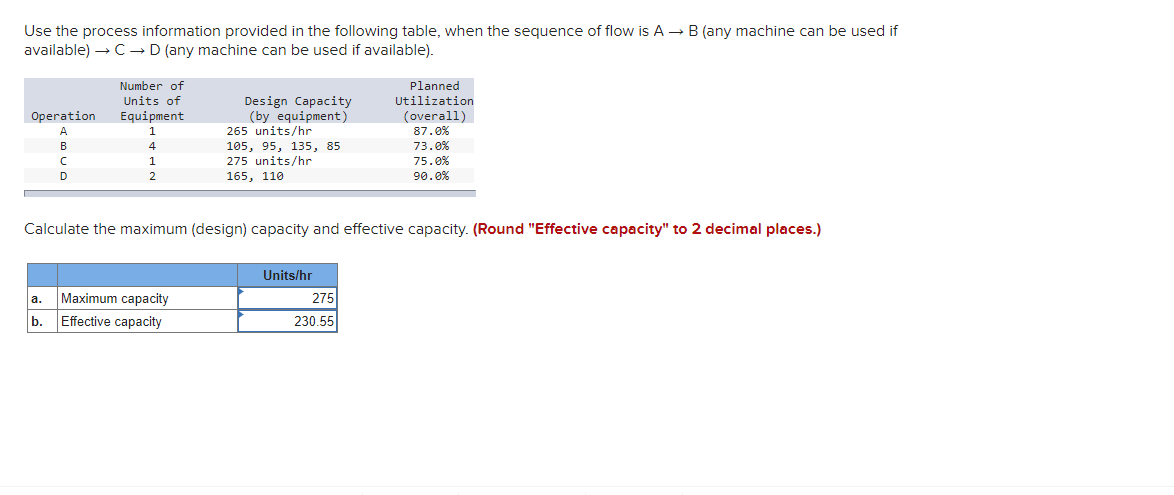

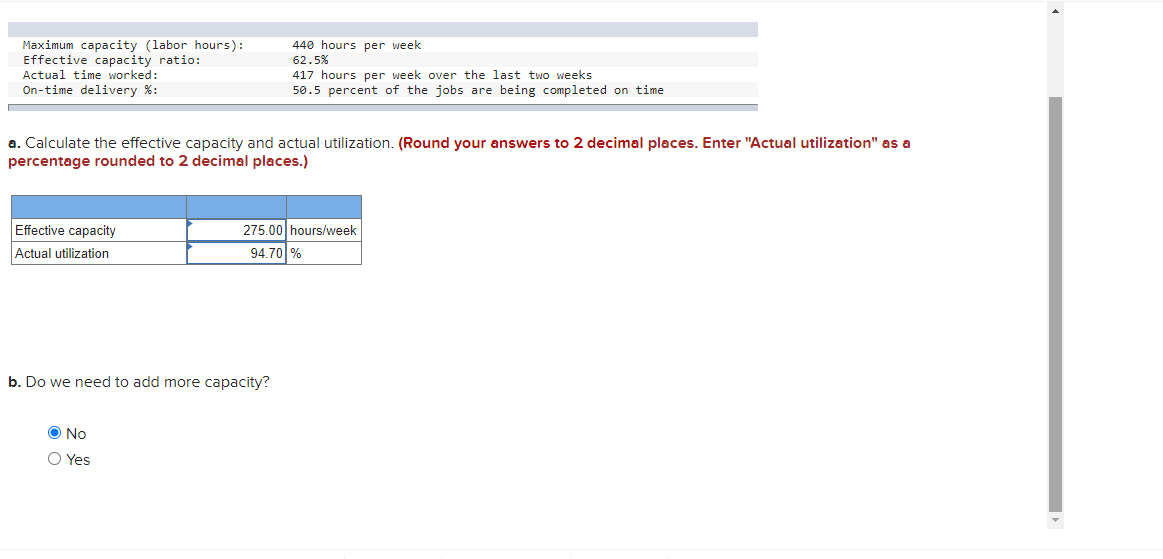

Use the process information provided in the following table, when the sequence of flow is A - B (any machine can be used if available) - C - D (any machine can be used if available). Number of Planned Units of Design Capacity Utilization Operation Equipment (by equipment) (overall) A 1 265 units/hr 87.0% CO 105, 95, 135, 85 73. 0% NPA 275 units/hr 75. 0% on 165, 110 90. 0% Calculate the maximum (design) capacity and effective capacity. (Round "Effective capacity" to 2 decimal places.) Units/hr a. Maximum capacity 275 b. Effective capacity 230.55Maximum capacity (labor hours): 440 hours per week Effective capacity ratio: 62.5% Actual time worked: 41? hours per week over the last two weeks Ontime delivery X: 58.5 percent of the jobs are being completed on time a. Calculate the effective capacity and actual utilization. {Round your answers to 2 decimal places. Enter \"Actual utilization" as a percentage rounded to 2 decimal places.) Eedive capacity Actual utilization b. Do we need to add more capacity? C) N0 0 Yes

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts