Question: Write a case study Write a case study 90 56 91 84 70 5 5 5 5 5 5 5 5 50 11 50 5

Write a case study

Write a case study

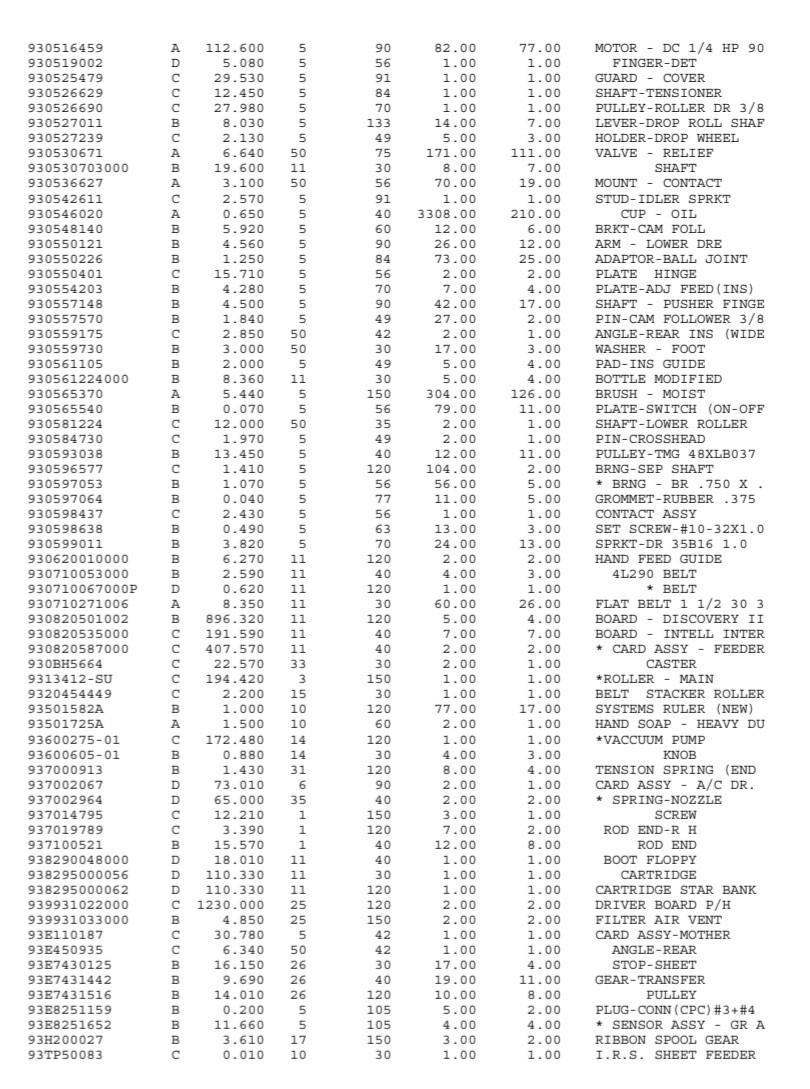

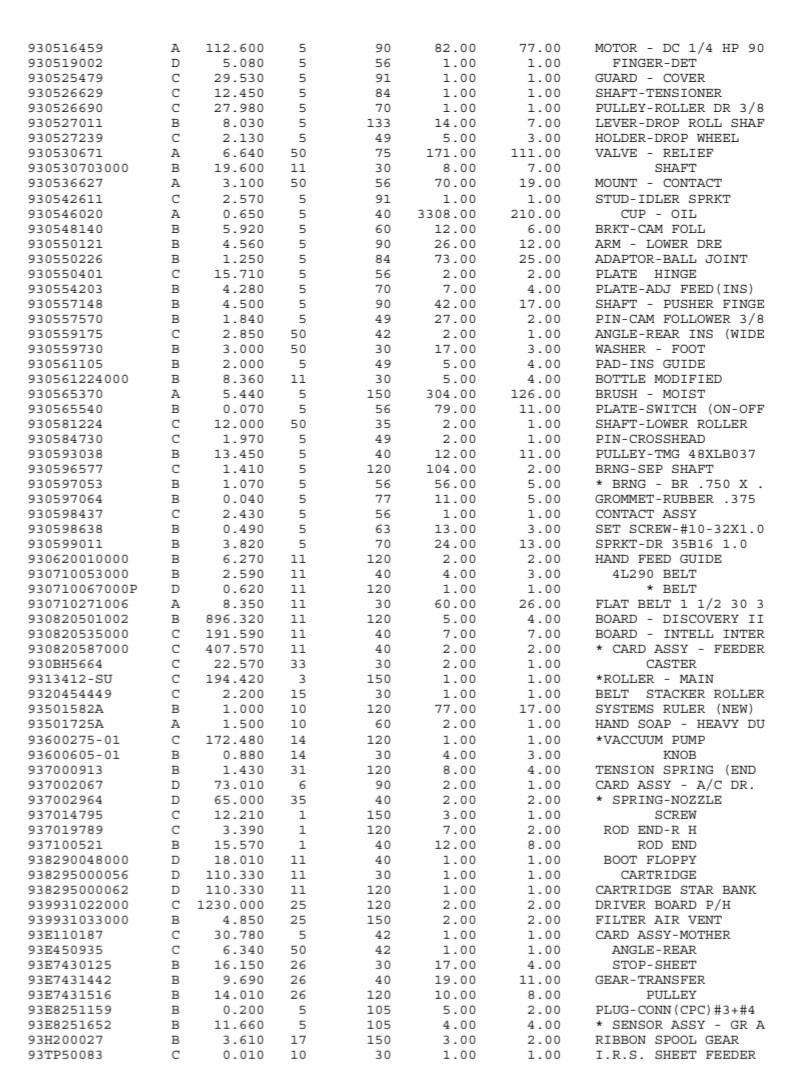

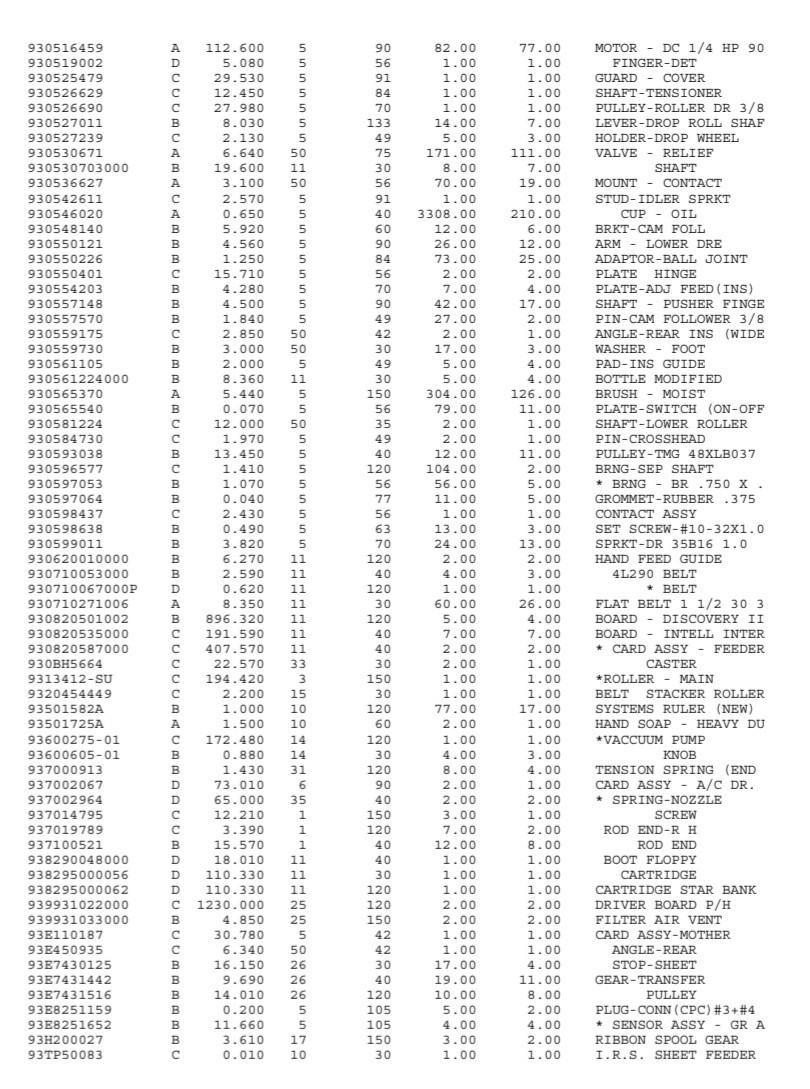

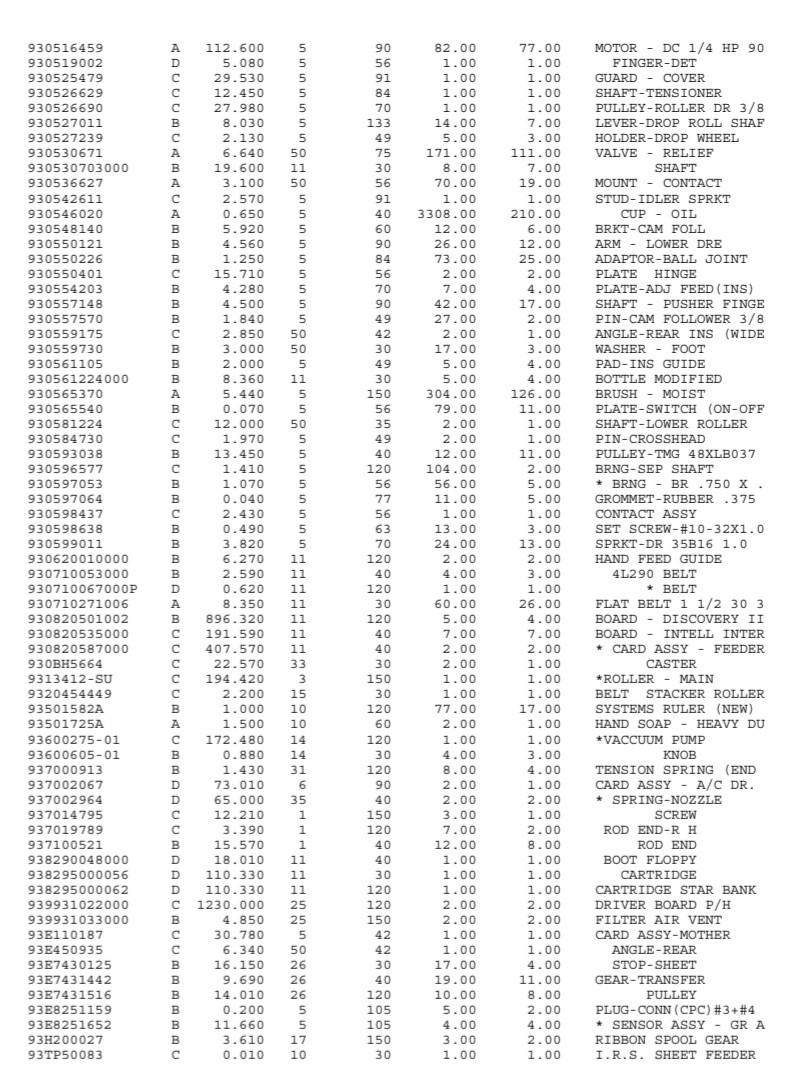

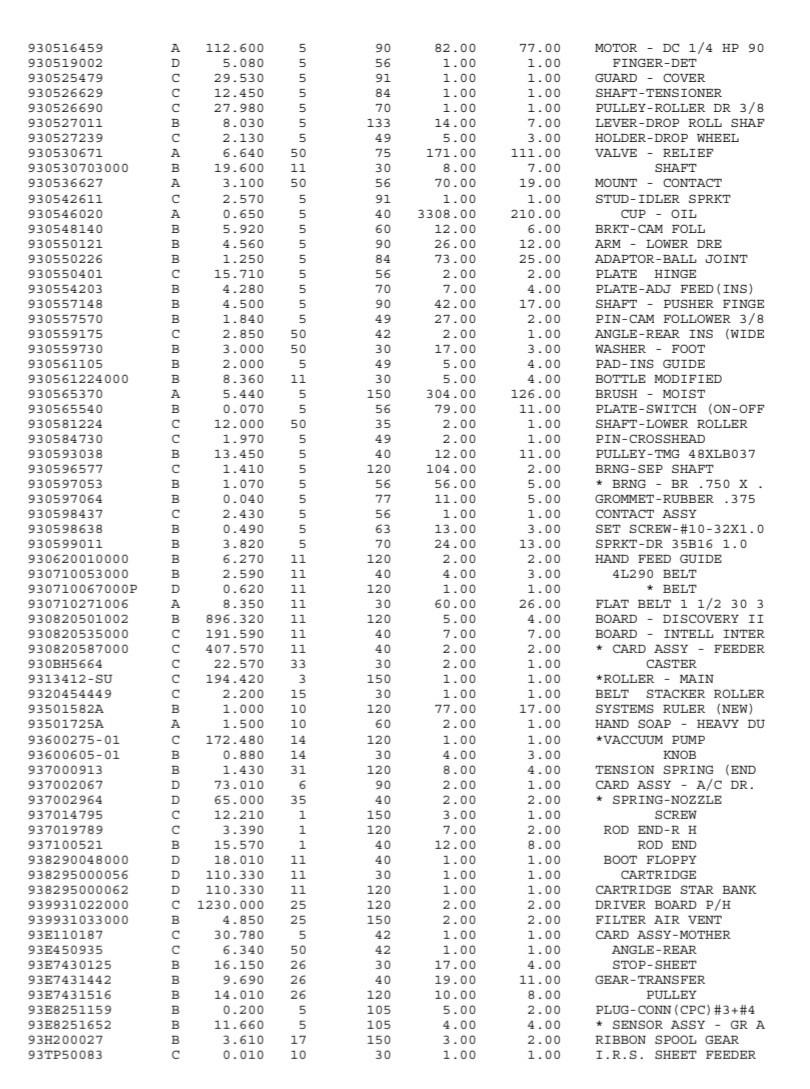

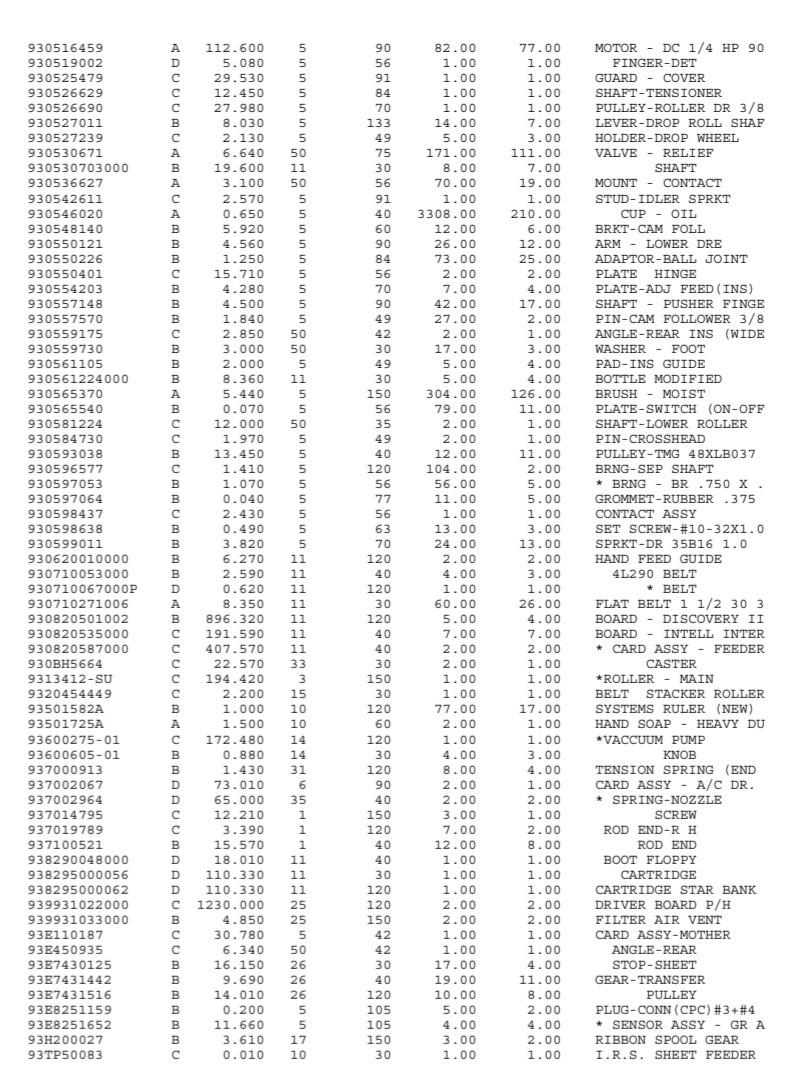

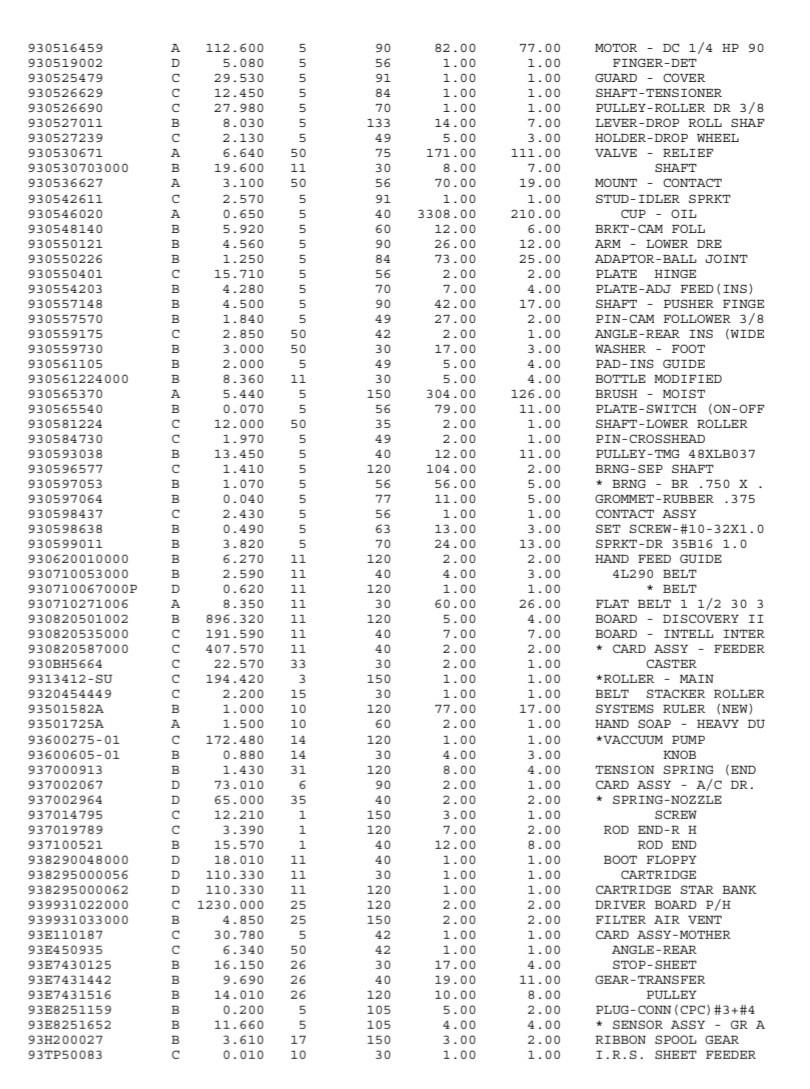

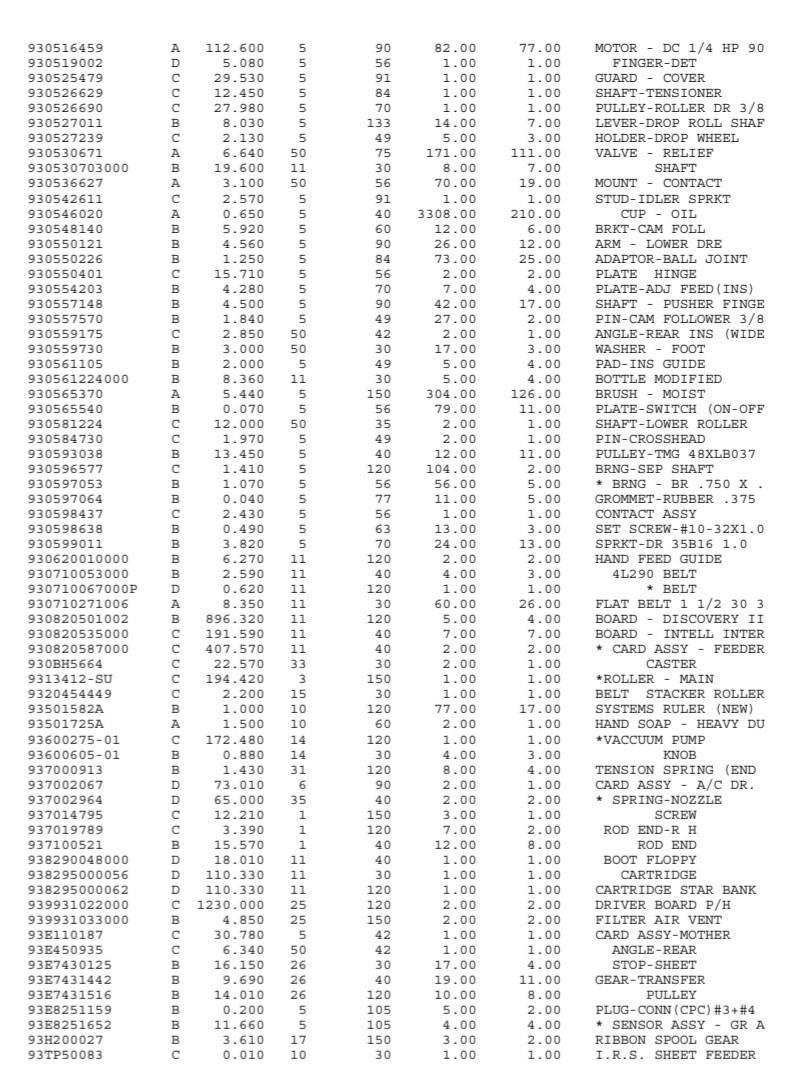

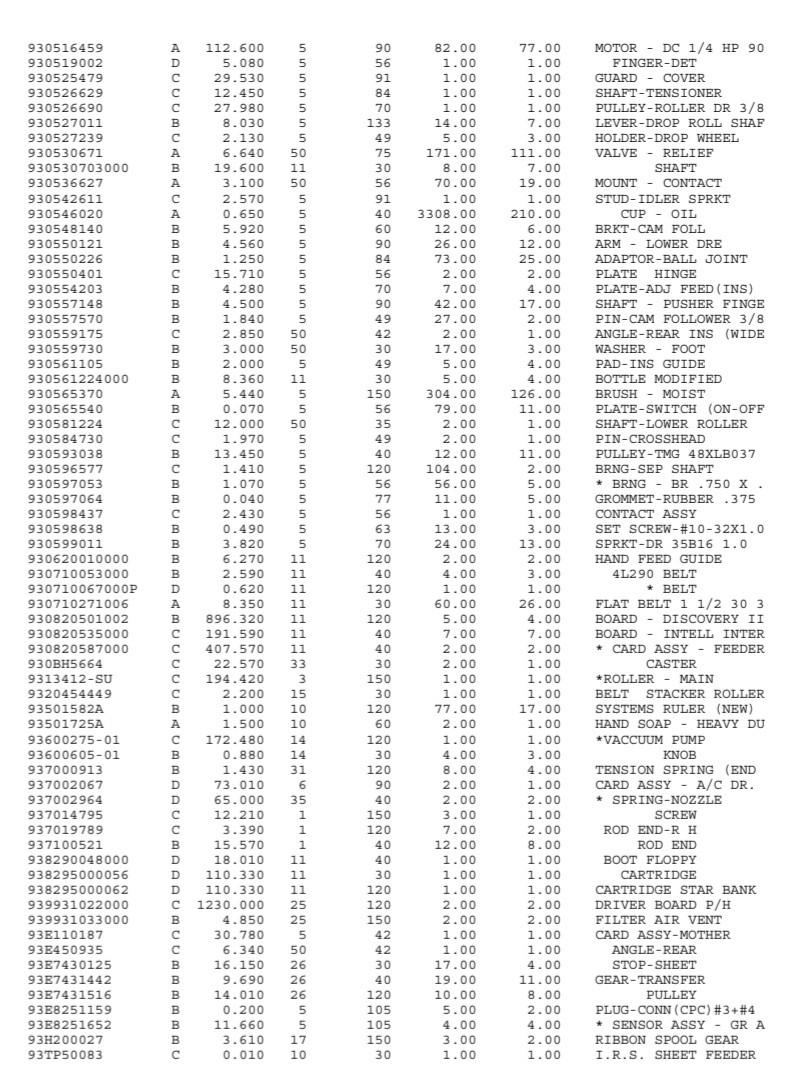

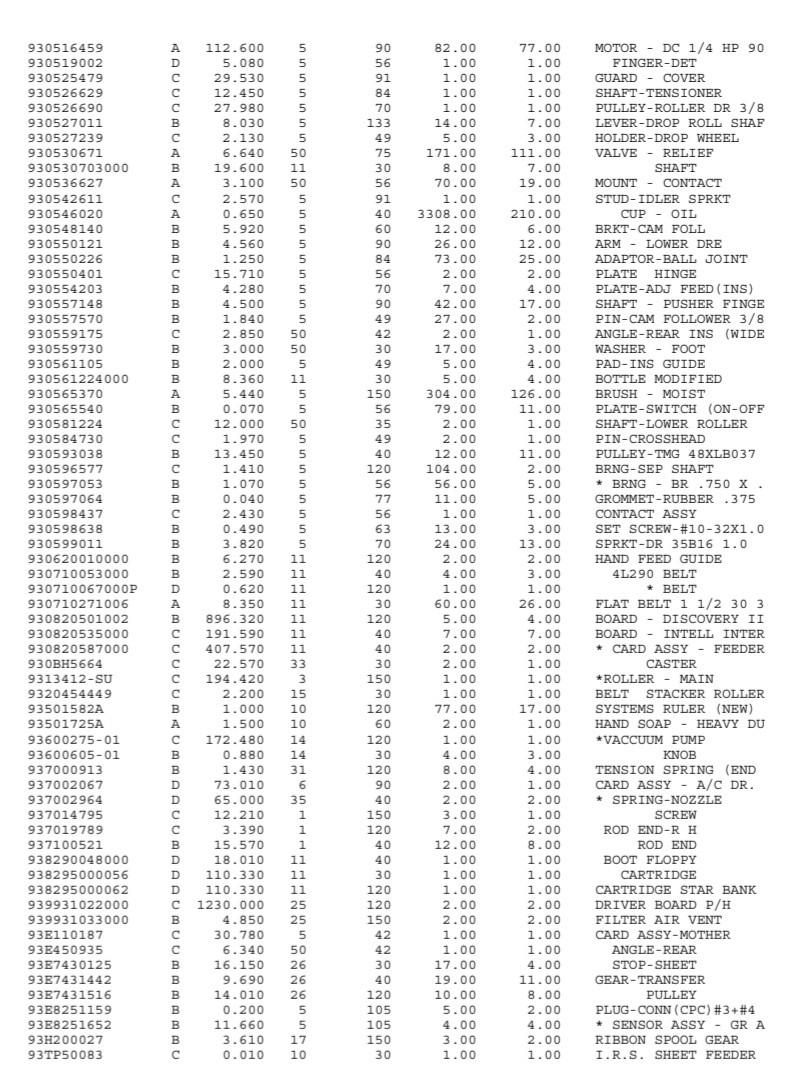

90 56 91 84 70 5 5 5 5 5 5 5 5 50 11 50 5 5 5 5 5 5 5 5 5 5 133 49 75 30 56 91 40 60 90 84 56 70 90 49 50 42 un 930516459 930519002 930525479 930526629 930526690 930527011 930527239 930530671 930530703000 930536627 930542611 930546020 930548140 930550121 930550226 930550401 930554203 930557148 930557570 930559175 930559730 930561105 930561224000 930565370 930565540 930581224 930584730 930593038 930596577 930597053 930597064 930598437 930598638 930599011 930620010000 930710053000 930710067000P 930710271006 930820501002 930820535000 930820587000 930BH5664 9313412-SU 9320454449 93501582A 93501725A 93600275-01 93600605-01 937000913 937002067 937002964 937014795 937019789 937100521 938290048000 938295000056 938295000062 939931022000 939931033000 938110187 938450935 93E7430125 93E7431442 93E7431516 93E8251159 93E8251652 93H200027 93TP50083 A 112.600 D 5.080 29.530 12.450 27.980 B 8.030 2.130 6.640 B 19.600 A 3.100 2.570 A 0.650 B 5.920 B 4.560 B 1.250 C 15.710 B 4.280 B 4.500 B 1.840 2.850 B 3.000 B 2.000 B 8.360 5.440 B 0.070 12.000 1.970 B 13.450 1.410 B 1.070 B 0.040 2.430 B 0.490 B 3.820 B 6.270 B 2.590 D 0.620 A 8.350 B 896.320 191.590 407.570 22.570 194.420 2.200 B 1.000 1.500 172.480 B 0.880 B 1.430 D 73.010 D 65.000 12.210 3.390 B B 15.570 D 18.010 D 110.330 D 110.330 C 1230.000 B 4.850 30.780 C 6.340 B 16.150 B 9.690 B 14.010 B 0.200 B 11.660 B B 3.610 0.010 50 5 11 5 5 50 5 5 5 5 5 5 5 5 5 11 11 11 11 11 11 11 33 3 15 10 10 14 14 30 49 30 150 56 35 49 40 120 56 77 56 63 70 120 40 120 30 120 40 40 30 150 30 120 60 120 30 120 90 40 150 120 40 40 30 120 120 150 42 42 30 40 120 105 105 150 30 82.00 1.00 1.00 1.00 1.00 14.00 5.00 171.00 8.00 70.00 1.00 3308.00 12.00 26.00 73.00 2.00 7.00 42.00 27.00 2.00 17.00 5.00 5.00 304.00 79.00 2.00 2.00 12.00 104.00 56.00 11.00 1.00 13.00 24.00 2.00 4.00 1.00 60.00 5.00 7.00 2.00 2.00 1.00 1.00 77.00 2.00 1.00 4.00 8.00 2.00 2.00 3.00 7.00 12.00 1.00 1.00 1.00 2.00 2.00 1.00 1.00 17.00 19.00 10.00 5.00 4.00 3.00 1.00 77.00 1.00 1.00 1.00 1.00 7.00 3.00 111.00 7.00 19.00 1.00 210.00 6.00 12.00 25.00 2.00 4.00 17.00 2.00 1.00 3.00 4.00 4.00 126.00 11.00 1.00 1.00 11.00 2.00 5.00 5.00 1.00 3.00 13.00 2.00 3.00 1.00 26.00 4.00 7.00 2.00 1.00 1.00 1.00 17.00 1.00 1.00 3.00 4.00 1.00 2.00 1.00 2.00 8.00 1.00 1.00 1.00 2.00 2.00 1.00 1.00 4.00 11.00 8.00 2.00 4.00 2.00 1.00 MOTOR - DC 1/4 HP 90 FINGER-DET GUARD - COVER SHAFT-TENSIONER PULLEY-ROLLER DR 3/8 LEVER-DROP ROLL SHAF HOLDER-DROP WHEEL VALVE - RELIEF SHAFT MOUNT - CONTACT STUD-IDLER SPRKT CUP - OIL BRKT - CAM FOLL ARM - LOWER DRE ADAPTOR-BALL JOINT PLATE HINGE PLATE-ADJ FEED (INS) SHAFT - PUSHER FINGE PIN-CAM FOLLOWER 3/8 ANGLE-REAR INS (WIDE WASHER - FOOT PAD-INS GUIDE BOTTLE MODIFIED BRUSH - MOIST PLATE-SWITCH (ON-OFF SHAFT-LOWER ROLLER PIN-CROSSHEAD PULLEY-TMG 48XLB037 BRNG-SEP SHAFT * BRNG - BR.750 X GROMMET-RUBBER.375 CONTACT ASSY SET SCREW-#10-32x1.0 SPRKT-DR 35B16 1.0 HAND FEED GUIDE 4L290 BELT + BELT FLAT BELT 1 1/2 30 3 BOARD - DISCOVERY II BOARD - INTELL INTER * CARD ASSY - FEEDER CASTER *ROLLER - MAIN BELT STACKER ROLLER SYSTEMS RULER (NEW) HAND SOAP - HEAVY DU *VACCUUM PUMP KNOB TENSION SPRING (END CARD ASSY - A/C DR. * SPRING-NOZZLE SCREW ROD END-RH ROD END BOOT FLOPPY CARTRIDGE CARTRIDGE STAR BANK DRIVER BOARD P/H FILTER AIR VENT CARD ASSY-MOTHER ANGLE-REAR STOP-SHEET GEAR-TRANSFER PULLEY PLUG-CONN (CPC) #3+ #4 + SENSOR ASSY - GR A RIBBON SPOOL GEAR I.R.S. SHEET FEEDER 31 6 35 1 1 1 11 11 11 25 25 5 50 26 26 26 5 5 17 10 3. Data The following data are for 219 representative items from the total part list of roughly 30,000 part numbers. For each part number, the following are given: Vendor Code: a pointer to information about the type of vendor. Unit Cost: best estimate of current cost per unit to purchase or produce the part. . Location Code: an indicator of where in the DC the item is held. Leadtime: approximate time for DC to receive a replenishment order Total Usage: number of units demanded from DC during previous year. Note that parts with zero usage are not necessarily obsolete. Because models of machines are introduced, age, and are retired, there tends to be some change in the usage rates from year to year, although the company has limited ability to predict how they will change in advance. Total Incidents: number of separate orders placed on the DC during the previous year. Because some parts are purchased in batches (e.g., a machine might require 12 sucker cups to be replaced at the same time), the number of incidents should always be less than the total usage (except in the case of returned parts or data entry errors). Description: short description of part. 3. Data The following data are for 219 representative items from the total part list of roughly 30,000 part numbers. For each part number, the following are given: Vendor Code: a pointer to information about the type of vendor. Unit Cost: best estimate of current cost per unit to purchase or produce the part. . Location Code: an indicator of where in the DC the item is held. Leadtime: approximate time for DC to receive a replenishment order Total Usage: number of units demanded from DC during previous year. Note that parts with zero usage are not necessarily obsolete. Because models of machines are introduced, age, and are retired, there tends to be some change in the usage rates from year to year, although the company has limited ability to predict how they will change in advance. Total Incidents: number of separate orders placed on the DC during the previous year. Because some parts are purchased in batches (e.g., a machine might require 12 sucker cups to be replaced at the same time), the number of incidents should always be less than the total usage (except in the case of returned parts or data entry errors). Description: short description of part. 3. Data The following data are for 219 representative items from the total part list of roughly 30,000 part numbers. For each part number, the following are given: Vendor Code: a pointer to information about the type of vendor. Unit Cost: best estimate of current cost per unit to purchase or produce the part. . Location Code: an indicator of where in the DC the item is held. Leadtime: approximate time for DC to receive a replenishment order Total Usage: number of units demanded from DC during previous year. Note that parts with zero usage are not necessarily obsolete. Because models of machines are introduced, age, and are retired, there tends to be some change in the usage rates from year to year, although the company has limited ability to predict how they will change in advance. Total Incidents: number of separate orders placed on the DC during the previous year. Because some parts are purchased in batches (e.g., a machine might require 12 sucker cups to be replaced at the same time), the number of incidents should always be less than the total usage (except in the case of returned parts or data entry errors). Description: short description of part. 3. Data The following data are for 219 representative items from the total part list of roughly 30,000 part numbers. For each part number, the following are given: Vendor Code: a pointer to information about the type of vendor. Unit Cost: best estimate of current cost per unit to purchase or produce the part. . Location Code: an indicator of where in the DC the item is held. Leadtime: approximate time for DC to receive a replenishment order Total Usage: number of units demanded from DC during previous year. Note that parts with zero usage are not necessarily obsolete. Because models of machines are introduced, age, and are retired, there tends to be some change in the usage rates from year to year, although the company has limited ability to predict how they will change in advance. Total Incidents: number of separate orders placed on the DC during the previous year. Because some parts are purchased in batches (e.g., a machine might require 12 sucker cups to be replaced at the same time), the number of incidents should always be less than the total usage (except in the case of returned parts or data entry errors). Description: short description of part. 930516459 930519002 930525479 930526629 930526690 930527011 930527239 930530671 930530703000 930536627 930542611 930546020 930548140 930550121 930550226 930550401 930554203 930557148 930557570 930559175 930559730 930561105 930561224000 930565370 930565540 930581224 930584730 930593038 930596577 930597053 930597064 930598437 930598638 930599011 930620010000 930710053000 930710067000P 930710271006 930820501002 930820535000 930820587000 930BH5664 9313412-SU 9320454449 93501582A 93501725A 93600275-01 93600605-01 937000913 937002067 937002964 937014795 937019789 937100521 938290048000 938295000056 938295000062 939931022000 939931033000 93E110187 93E450935 93E7430125 93E7431442 93E7431516 93E8251159 93E8251652 93H200027 93TP50083 iniinin A 112.600 D 5.080 29.530 C C 12.450 5 27.980 5 B 8.030 5 C 2.130 5 A 6.640 50 B 11 A 3.100 50 C 2.570 5 A 0.650 5 B 5.920 5 B 4.560 5 B 1.250 5 15.710 5 B 4.280 5 B 4.500 5 B 1.840 5 C 2.850 B 3.000 B 2.000 5 B 8.360 11 A 5.440 5 B 0.070 5 C 12.000 50 1.970 5 B 13.450 5 C 1.410 5 B 5 1.070 0.040 B 5 C 2.430 5 B 0.490 5 B 3.820 5 B 6.270 11 B 2.590 11 D 0.620 11 A 8.350 11 11 B 896.320 191.590 407.570 11 11 C 22.570 33 C 194.420 3 C 2.200 15 B 10 1.000 1.500 10 A C 172.480 14 B 0.880 14 B 1.430 31 D 73.010 6 D 65.000 35 C 12.210 3.390 15.570 B D 18.010 D 110.330 D 110.330 C 1230.000 B 4.850 30.780 C 6.340 16.150 B 9.690 14.010 B B B B 0.200 11.660 B 3.610 C 0.010 19.600 5 5 5 50 50 FFSEEEEEEENNNNNNN 1 1 1 11 11 11 25 25 5 50 26 26 26 5 5 17 10 90 56 91 84 70 133 49 75 30 56 91 40 60 90 84 56 70 90 49 42 30 49 30 150 56 35 49 40 120 56 77 56 63 70 120 40 120 30 120 40 40 30 150 30 120 60 120 30 120 90 40 150 120 40 40 30 120 120 150 42 42 30 40 120 105 105 150 30 82.00 1.00 1.00 1.00 1.00 14.00 5.00 171.00 8.00 70.00 1.00 3308.00 12.00 26.00 73.00 2.00 7.00 42.00 27.00 2.00 17.00 5.00 5.00 304.00 79.00 2.00 2.00 12.00 104.00 56.00 11.00 1.00 13.00 24.00 2.00 4.00 1.00 60.00 5.00 7.00 2.00 2.00 1.00 1.00 77.00 2.00 1.00 4.00 8.00 2.00 2.00 3.00 7.00 12.00 1.00 1.00 1.00 2.00 2.00 1.00 1.00 17.00 19.00 10.00 5.00 4.00 3.00 1.00 77.00 1.00 1.00 1.00 1.00 7.00 3.00 111.00 7.00 19.00 1.00 210.00 6.00 12.00 25.00 2.00 4.00 17.00 2.00 1.00 3.00 4.00 4.00 126.00 11.00 1.00 1.00 11.00 2.00 5.00 5.00 1.00 3.00 13.00 2.00 3.00 1.00 26.00 4.00 7.00 2.00 1.00 1.00 1.00 17.00 1.00 1.00 3.00 4.00 1.00 2.00 1.00 2.00 8.00 1.00 1.00 1.00 2.00 2.00 1.00 1.00 4.00 11.00 8.00 2.00 4.00 2.00 1.00 MOTOR DC 1/4 HP 90 FINGER-DET GUARD COVER SHAFT-TENSIONER PULLEY-ROLLER DR 3/8 LEVER-DROP ROLL SHAF HOLDER-DROP WHEEL VALVE RELIEF SHAFT MOUNT CONTACT - STUD-IDLER SPRKT CUP - OIL BRKT-CAM FOLL ARM LOWER DRE - ADAPTOR-BALL JOINT PLATE HINGE PLATE-ADJ FEED (INS) SHAFT PUSHER FINGE PIN-CAM FOLLOWER 3/8 ANGLE-REAR INS (WIDE WASHER FOOT - PAD-INS GUIDE BOTTLE MODIFIED BRUSH MOIST PLATE-SWITCH (ON-OFF SHAFT-LOWER ROLLER PIN-CROSSHEAD PULLEY-TMG 48XLB037 BRNG-SEP SHAFT - * BRNG BR .750 X . GROMMET-RUBBER .375 CONTACT ASSY SET SCREW-#10-32X1.0 SPRKT-DR 35B16 1.0 HAND FEED GUIDE 4L290 BELT BELT FLAT BELT 1 1/2 30 3 BOARD DISCOVERY II BOARD INTELL INTER - * CARD ASSY - FEEDER CASTER *ROLLER - MAIN BELT STACKER ROLLER SYSTEMS RULER (NEW) HAND SOAP HEAVY DU *VACCUUM PUMP KNOB TENSION SPRING (END CARD ASSY - A/C DR. * SPRING-NOZZLE SCREW ROD END-R H ROD END BOOT FLOPPY CARTRIDGE CARTRIDGE STAR BANK DRIVER BOARD P/H FILTER AIR VENT CARD ASSY-MOTHER ANGLE-REAR STOP-SHEET GEAR-TRANSFER PULLEY PLUG-CONN (CPC) #3+#4 * SENSOR ASSY GR A RIBBON SPOOL GEAR I.R.S. SHEET FEEDER

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock