Question: Write a manual NC code to perform the mentioned tasks: Commonly used commands: G17: XY, G18: XZ, G19: YZ planes, G20: inch, G21: ( mathrm{mm}

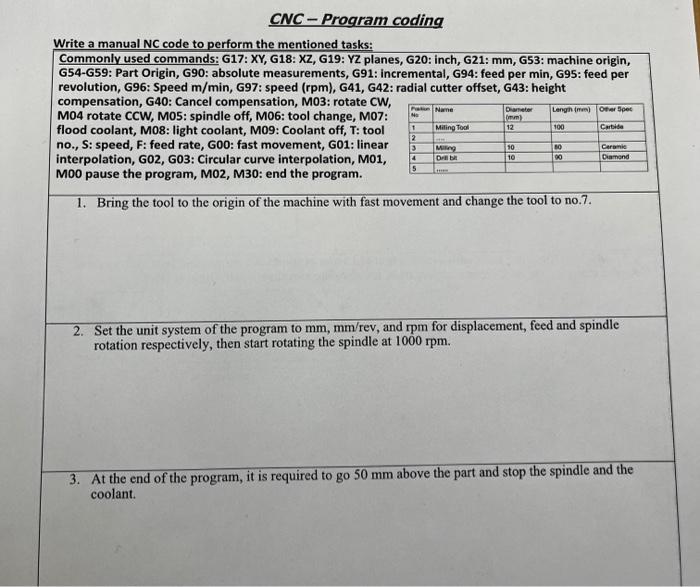

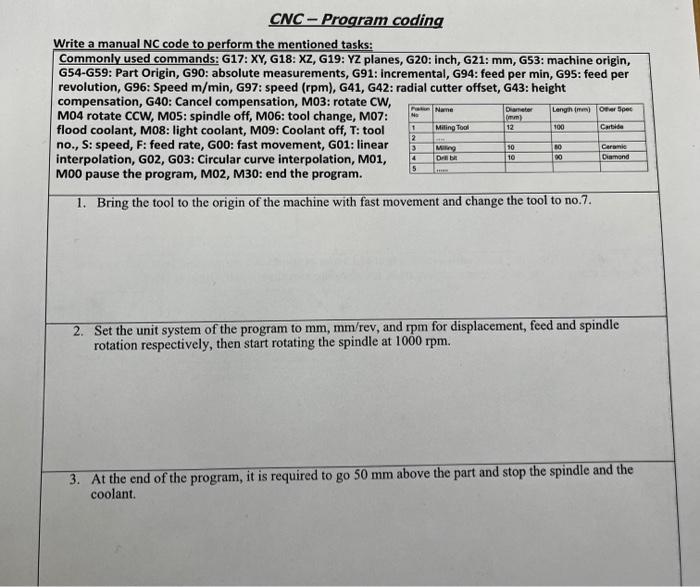

Write a manual NC code to perform the mentioned tasks: Commonly used commands: G17: XY, G18: XZ, G19: YZ planes, G20: inch, G21: mm, G53: machine origin, G54-G59: Part Origin, G90: absolute measurements, G91: incremental, G94: feed per min, G95: feed per revolution, G96: Speed m/min, G97: speed (rpm), G41, G42: radial cutter offset, G43: height compensation, G40: Cancel compensation, M03: rotate CW, M04 rotate CCW, M05: spindle off, M06: tool change, M07: flood coolant, M08: light coolant, M09: Coolant off, T: tool no., S: speed, F: feed rate, G00: fast movement, G01: linear interpolation, G02, G03: Circular curve interpolation, M01, M00 pause the program, M02, M30: end the program. 1. Bring the tool to the origin of the machine with fast movement and change the tool to no.7. 2. Set the unit system of the program to mm,mm/rev, and rpm for displacement, feed and spindle rotation respectively, then start rotating the spindle at 1000rpm. 3. At the end of the program, it is required to go 50mm above the part and stop the spindle and the coolant. Write a manual NC code to perform the mentioned tasks: Commonly used commands: G17: XY, G18: XZ, G19: YZ planes, G20: inch, G21: mm, G53: machine origin, G54-G59: Part Origin, G90: absolute measurements, G91: incremental, G94: feed per min, G95: feed per revolution, G96: Speed m/min, G97: speed (rpm), G41, G42: radial cutter offset, G43: height compensation, G40: Cancel compensation, M03: rotate CW, M04 rotate CCW, M05: spindle off, M06: tool change, M07: flood coolant, M08: light coolant, M09: Coolant off, T: tool no., S: speed, F: feed rate, G00: fast movement, G01: linear interpolation, G02, G03: Circular curve interpolation, M01, M00 pause the program, M02, M30: end the program. 1. Bring the tool to the origin of the machine with fast movement and change the tool to no.7. 2. Set the unit system of the program to mm,mm/rev, and rpm for displacement, feed and spindle rotation respectively, then start rotating the spindle at 1000rpm. 3. At the end of the program, it is required to go 50mm above the part and stop the spindle and the coolant. Write a manual NC code to perform the mentioned tasks: Commonly used commands: G17: XY, G18: XZ, G19: YZ planes, G20: inch, G21: mm, G53: machine origin, G54-G59: Part Origin, G90: absolute measurements, G91: incremental, G94: feed per min, G95: feed per revolution, G96: Speed m/min, G97: speed (rpm), G41, G42: radial cutter offset, G43: height compensation, G40: Cancel compensation, M03: rotate CW, M04 rotate CCW, M05: spindle off, M06: tool change, M07: flood coolant, M08: light coolant, M09: Coolant off, T: tool no., S: speed, F: feed rate, G00: fast movement, G01: linear interpolation, G02, G03: Circular curve interpolation, M01, M00 pause the program, M02, M30: end the program. 1. Bring the tool to the origin of the machine with fast movement and change the tool to no.7. 2. Set the unit system of the program to mm,mm/rev, and rpm for displacement, feed and spindle rotation respectively, then start rotating the spindle at 1000rpm. 3. At the end of the program, it is required to go 50mm above the part and stop the spindle and the coolant. Write a manual NC code to perform the mentioned tasks: Commonly used commands: G17: XY, G18: XZ, G19: YZ planes, G20: inch, G21: mm, G53: machine origin, G54-G59: Part Origin, G90: absolute measurements, G91: incremental, G94: feed per min, G95: feed per revolution, G96: Speed m/min, G97: speed (rpm), G41, G42: radial cutter offset, G43: height compensation, G40: Cancel compensation, M03: rotate CW, M04 rotate CCW, M05: spindle off, M06: tool change, M07: flood coolant, M08: light coolant, M09: Coolant off, T: tool no., S: speed, F: feed rate, G00: fast movement, G01: linear interpolation, G02, G03: Circular curve interpolation, M01, M00 pause the program, M02, M30: end the program. 1. Bring the tool to the origin of the machine with fast movement and change the tool to no.7. 2. Set the unit system of the program to mm,mm/rev, and rpm for displacement, feed and spindle rotation respectively, then start rotating the spindle at 1000rpm. 3. At the end of the program, it is required to go 50mm above the part and stop the spindle and the coolant

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts