Question: Write the formulas that calculate the total production time used for casting, machin- ing, and final assembly. Enter a mathematical formula in the objective

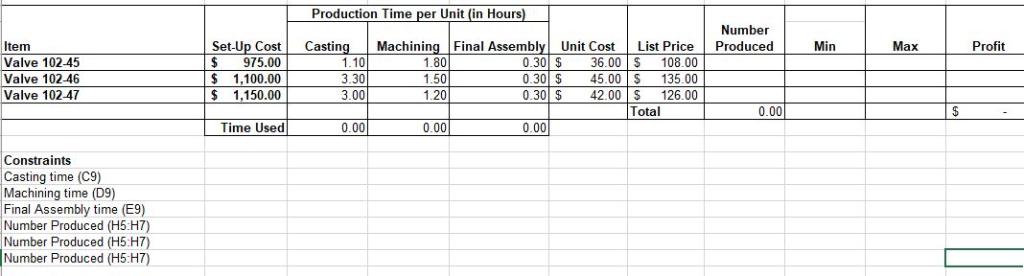

Write the formulas that calculate the total production time used for casting, machin- ing, and final assembly. Enter a mathematical formula in the objective cell, and then enter formulas to link the objective cell with the variable cells. Add sample values to the variable cells to ensure that your worksheet is set up correctly and produces the expected results. Create a constraints table in the worksheet that identifies the constraints in this problem. Use Solver to determine the optimal combination of valves to build to maximize profit. Produce an answer report of your solution. Which constraints could you modify to maximize the total profit? Place your recommendations in a text box on the answer report worksheet. Item Valve 102-45 Valve 102-46 Valve 102-47 Constraints Casting time (C9) Machining time (D9) Final Assembly time (E9) Number Produced (H5 H7) Number Produced (H5 H7) Number Produced (H5:H7) Set-Up Cost $ 975.00 $1,100.00 $ 1,150.00 Time Used Production Time per Unit (in Hours) Casting Machining Final Assembly Unit Cost 0.30 $ 0.30 $ 0.30 S 1.10 3.30 3.00 0.00 1.80 1.50 1.20 0.00 0.00 List Price 36.00 $ 108.00 45.00 $ 135.00 42.00 S 126.00 Total Number Produced 0.00 Min Max $ Profit

Step by Step Solution

3.43 Rating (159 Votes )

There are 3 Steps involved in it

To set up the worksheet 1 Enter the formulas for total production time used for casting machining an... View full answer

Get step-by-step solutions from verified subject matter experts