Question: yellow group Leeds International Study Centre Foundation Year Engineering, Science and Computing Problem D: electric motor design used in mining Engineering equipment used in mines

yellow group

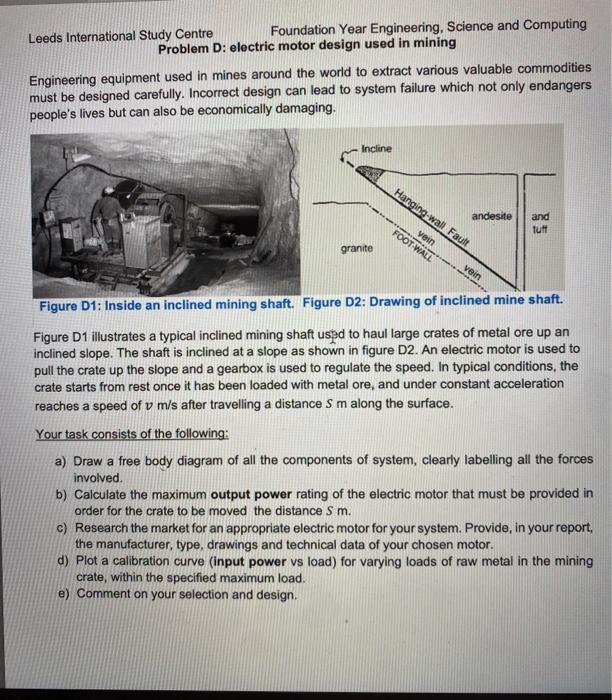

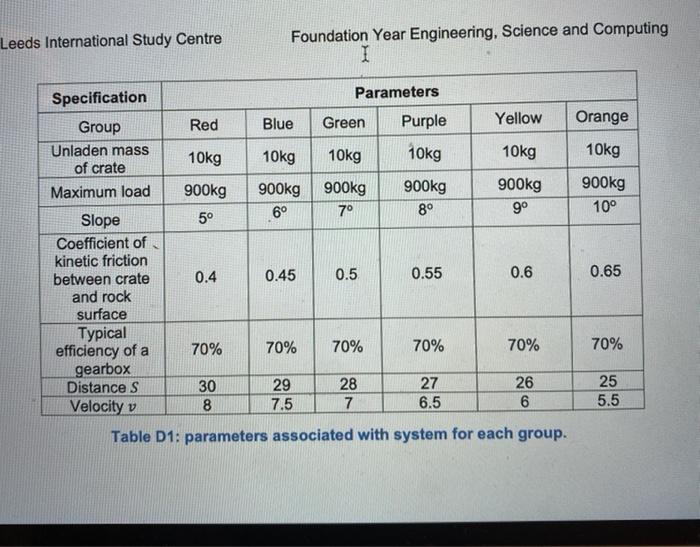

yellow group Leeds International Study Centre Foundation Year Engineering, Science and Computing Problem D: electric motor design used in mining Engineering equipment used in mines around the world to extract various valuable commodities must be designed carefully. Incorrect design can lead to system failure which not only endangers people's lives but can also be economically damaging. Incline Hanging wall Fault vein "FOOTWALE andesite and tuft granite vein Figure D1: Inside an inclined mining shaft. Figure D2: Drawing of inclined mine shaft. Figure D1 illustrates a typical inclined mining shaft uspd to haul large crates of metal ore up an inclined slope. The shaft is inclined at a slope as shown in figure D2. An electric motor is used to pull the crate up the slope and a gearbox is used to regulate the speed. In typical conditions, the crate starts from rest once it has been loaded with metal ore, and under constant acceleration reaches a speed of v m/s after travelling a distance S m along the surface. Your task consists of the following: a) Draw a free body diagram of all the components of system, clearly labelling all the forces involved b) Calculate the maximum output power rating of the electric motor that must be provided in order for the crate to be moved the distance S m. c) Research the market for an appropriate electric motor for your system. Provide, in your report, the manufacturer, type, drawings and technical data of your chosen motor. d) Plot a calibration curve (input power vs load) for varying loads of raw metal in the mining crate, within the specified maximum load. e) Comment on your selection and design. Leeds International Study Centre Foundation Year Engineering, Science and Computing I Orange 10kg 900kg 10 Specification Parameters Group Red Blue Green Purple Yellow Unladen mass 10kg 10kg 10kg 10kg 10kg of crate Maximum load 900kg 900kg 900kg 900kg 900kg 6 7 8 g Slope 5 Coefficient of kinetic friction between crate 0.4 0.45 0.5 0.55 0.6 and rock surface Typical efficiency of a 70% 70% 70% 70% 70% gearbox Distance S 30 29 28 27 26 Velocity v 8 7.5 7 6.5 6 Table D1: parameters associated with system for each group. 0.65 70% 25 5.5 Leeds International Study Centre Foundation Year Engineering, Science and Computing Problem D: electric motor design used in mining Engineering equipment used in mines around the world to extract various valuable commodities must be designed carefully. Incorrect design can lead to system failure which not only endangers people's lives but can also be economically damaging. Incline Hanging wall Fault vein "FOOTWALE andesite and tuft granite vein Figure D1: Inside an inclined mining shaft. Figure D2: Drawing of inclined mine shaft. Figure D1 illustrates a typical inclined mining shaft uspd to haul large crates of metal ore up an inclined slope. The shaft is inclined at a slope as shown in figure D2. An electric motor is used to pull the crate up the slope and a gearbox is used to regulate the speed. In typical conditions, the crate starts from rest once it has been loaded with metal ore, and under constant acceleration reaches a speed of v m/s after travelling a distance S m along the surface. Your task consists of the following: a) Draw a free body diagram of all the components of system, clearly labelling all the forces involved b) Calculate the maximum output power rating of the electric motor that must be provided in order for the crate to be moved the distance S m. c) Research the market for an appropriate electric motor for your system. Provide, in your report, the manufacturer, type, drawings and technical data of your chosen motor. d) Plot a calibration curve (input power vs load) for varying loads of raw metal in the mining crate, within the specified maximum load. e) Comment on your selection and design. Leeds International Study Centre Foundation Year Engineering, Science and Computing I Orange 10kg 900kg 10 Specification Parameters Group Red Blue Green Purple Yellow Unladen mass 10kg 10kg 10kg 10kg 10kg of crate Maximum load 900kg 900kg 900kg 900kg 900kg 6 7 8 g Slope 5 Coefficient of kinetic friction between crate 0.4 0.45 0.5 0.55 0.6 and rock surface Typical efficiency of a 70% 70% 70% 70% 70% gearbox Distance S 30 29 28 27 26 Velocity v 8 7.5 7 6.5 6 Table D1: parameters associated with system for each group. 0.65 70% 25 5.5

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts