Question: You are a process optimization consultant and asked to design a shipyard based on the following information. The shipbuilding process will have nine stages (Reference:

You are a process optimization consultant and asked to design a shipyard based on the following information.

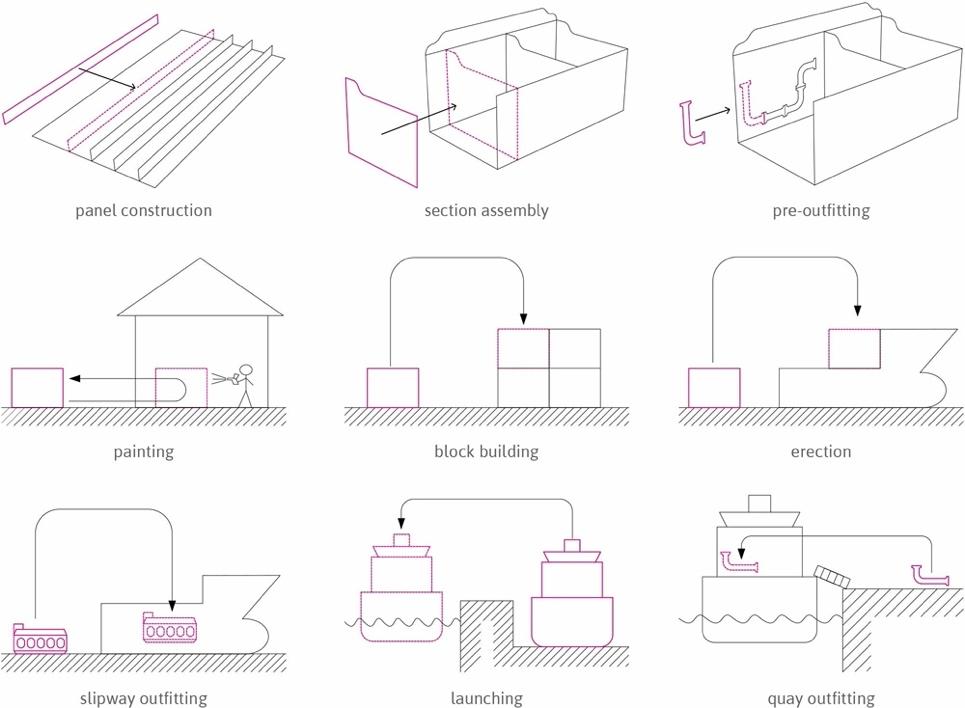

- The shipbuilding process will have nine stages (Reference: floorganise.com), as illustrated below.

- The process cycle time is 70 weeks.

- Slipway outfitting and quay outfitting have equal and most extended process times (21 weeks each).

- All other stations have different process times in weeks or multiples (all integers).

1. Draw the assembly line. Show names and process times. (1 points)

2. Calculate the capacity of the shipyard. (1 points)

3. Add three parallel lines to the system to get the best capacity. Draw the new assembly line and calculate the bottleneck, cycle time and the new capacity. (2 points)

4. If you increase the efficiency of the new bottleneck and reduce its process time by 50%, what will be the new bottleneck, cycle time and capacity? Please draw the new assembly line and show your calculations. (2 points)

5. Make sure your assignment has a professional look (1 point)

panel construction section assembly pre-outfitting slipway outfitting launching quay outfittingStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts