Question: You are currently preparing for the year - end audit of Supa Glass Limited ( SG ) for the year ended 3 1 August 2

You are currently preparing for the yearend audit of Supa Glass Limited SG for the year ended August SG is listed on the JSE Securities Exchange. The audit must be completed before September

SG is a new audit client to your audit firm and you have already gathered information to gain an understanding of the entity and its environment, including its system of internal control.

SG is a highly focused business based on a customerdriven culture that places partnerships with customers at the core of its business. Their drive for operational excellence has enabled the delivery of lower costs, improved quality, and innovative solutions. Strong cash flows from operations in previous years have enabled the group to comfortably fund investments to support its existing operations and build additional capacity. In the current financial year, operating profit has, however, been negatively impacted by the effect of a strong rand on selling prices of tableware which competes directly with imports. This has placed cash flow under pressure. The company has therefore decided to also sell to smaller customers from a warehouse in Kempton Park. A longterm lease agreement has been entered into for this warehouse. Commercial container glass is made by melting silica sand, soda ash, and limestone or melting recycled glass cullet The holding bin of the furnace is filled with a batch of either raw materials or recycled glass. From the holding bin of the furnace, the raw materials are continuously fed to the furnace where these are converted to molten glass and maintained at temperatures in excess of deg C Molten glass is continuously withdrawn through a submerged throat where it flows to the refinery area of the furnace and is cooled to approximately deg C before being delivered to the individual bottlemaking machines via the forehearths. The molten glass then enters the feeder to the bottlemaking machine, where the streams of glass are cut into pieces of predetermined weight gobs each of which is required to make a single bottle. These gobs of molten glass are then individually fed into the molds of the bottlemaking machine. The furnaces are fully computerized, and critical parameters are controlled within very close tolerance margins. SGs furnaces are designed to be the most modern in the world with a productive lifespan of more than ten years. The lifespan of the refractory lining part of the furnace is only three years. The company must rebuild a furnace after the threeyear lifespan of the refractory by replacing only the refractory of the furnace.

PROPERTY, PLANT AND EQUIPMENT

Accounting policy: Property, plant, and equipment

Property, plant, and equipment are carried at cost less accumulated depreciation and impairment losses. Depreciation is charged on a straightline basis over the estimated useful lives of each component of an item of property, plant, and equipment. Land is not depreciated. The estimated useful life of plant and machinery is between three and ten years. Where appropriate, and if material, expected residual values are taken into account in determining the depreciable values of assets.

Accounting policy: Investment property

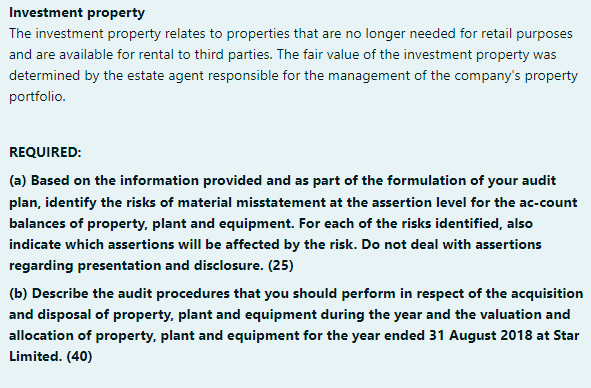

Investment property is stated at fair value at the balance sheet date. Gains or losses arising from changes in the fair value of investment property are included in profit or loss for the period in which they arise.

Acquisitions

Capital expenditure of SG amounted to R million in the current year. The capital expenditure projects were:

Bellville number furnace refractory rebuilt at the end of its threeyear useful life;

Glass recycling cullet plant in Pretoria, constructed by an established international firm; Glass forming machines at the Wadeville plant, bought in Italy and installed by the company; and A third furnace and production line at Clayville, constructed by an established international firm. During the year, all glass manufacturing facilities operated at full capacity and also above the standard efficiency. In addition to the above capital projects, the Bellville number furnace will be rebuilt during July in the next financial year, adding tons of capacity. This will result in a increase in the total glass capacity of SG

Disposals

SG sold special glassblowing equipment, used for the manufacture of leadcut glass, to an artist from the White River vicinity. At yearend, this equipment was not yet delivered to the artists studio due to delays by the building contractors in the completion of his studio. The equipment had already been packaged and full payment for the equipment was received, but the artist requested the company not to deliver it Ownership has passed to the artist in White River.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock