Question: You are tasked with designing a membrane separation unit to selectively purify oxygen from an air stream. Here, you can assume that air feedstock is

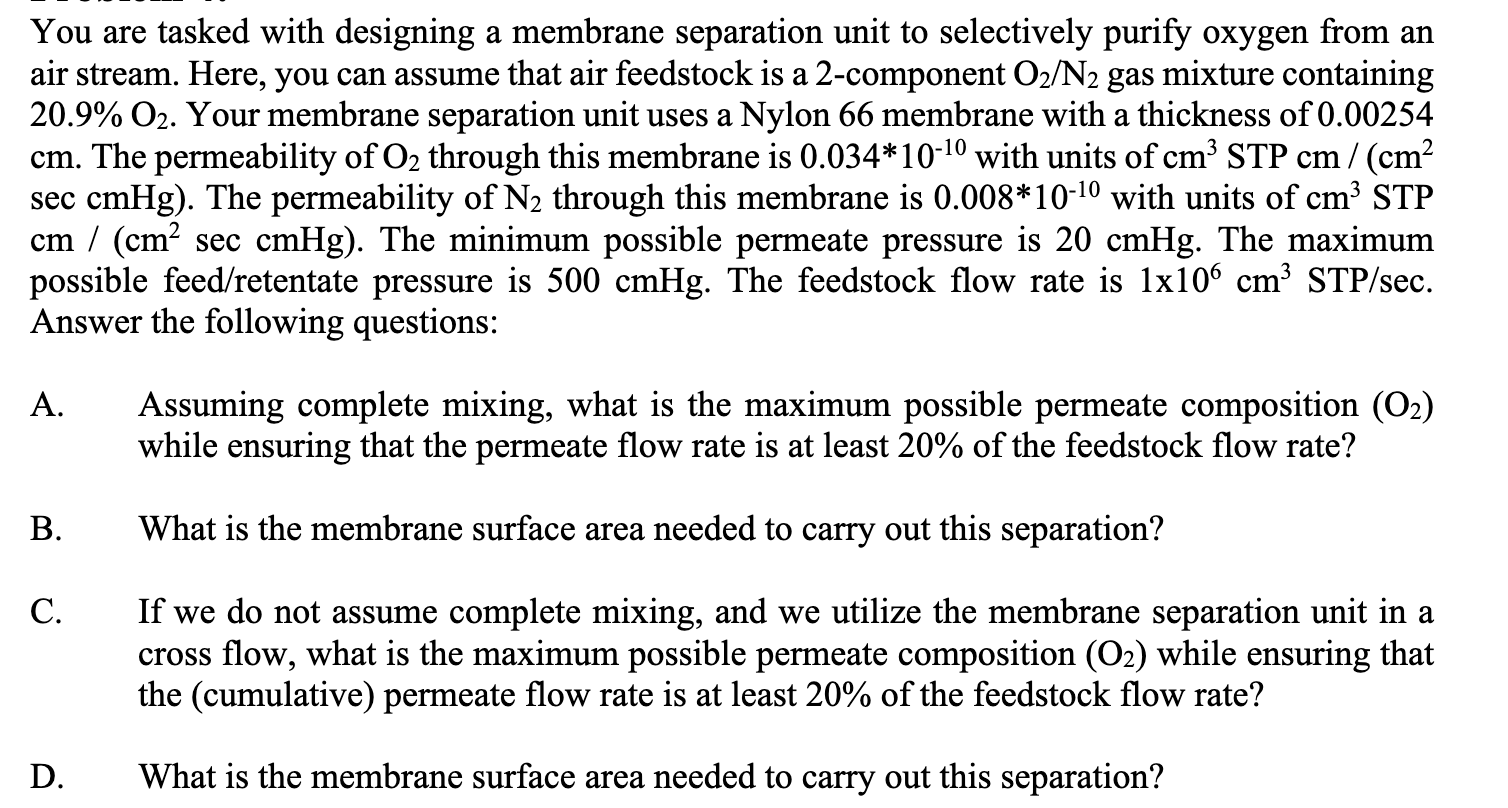

You are tasked with designing a membrane separation unit to selectively purify oxygen from an air stream. Here, you can assume that air feedstock is a 2-component Oz/N2 gas mixture containing 20.9% O2. Your membrane separation unit uses a Nylon 66 membrane with a thickness of 0.00254 cm. The permeability of O2 through this membrane is 0.034*10-10 with units of cm STP cm/(cm? sec cmHg). The permeability of N2 through this membrane is 0.008*10-10 with units of cm3 STP cm / (cm sec cmHg). The minimum possible permeate pressure is 20 cmHg. The maximum possible feed/retentate pressure is 500 cmHg. The feedstock flow rate is 1x106 cm STP/sec. Answer the following questions: A. Assuming complete mixing, what is the maximum possible permeate composition (O2) while ensuring that the permeate flow rate is at least 20% of the feedstock flow rate? B. What is the membrane surface area needed to carry out this separation? C. If we do not assume complete mixing, and we utilize the membrane separation unit in a cross flow, what is the maximum possible permeate composition (O2) while ensuring that the (cumulative) permeate flow rate is at least 20% of the feedstock flow rate? D. What is the membrane surface area needed to carry out this separation

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts