Question: You have recently started a new job as a manufacturing engineer for a machining company. As part of your new job, you have been asked

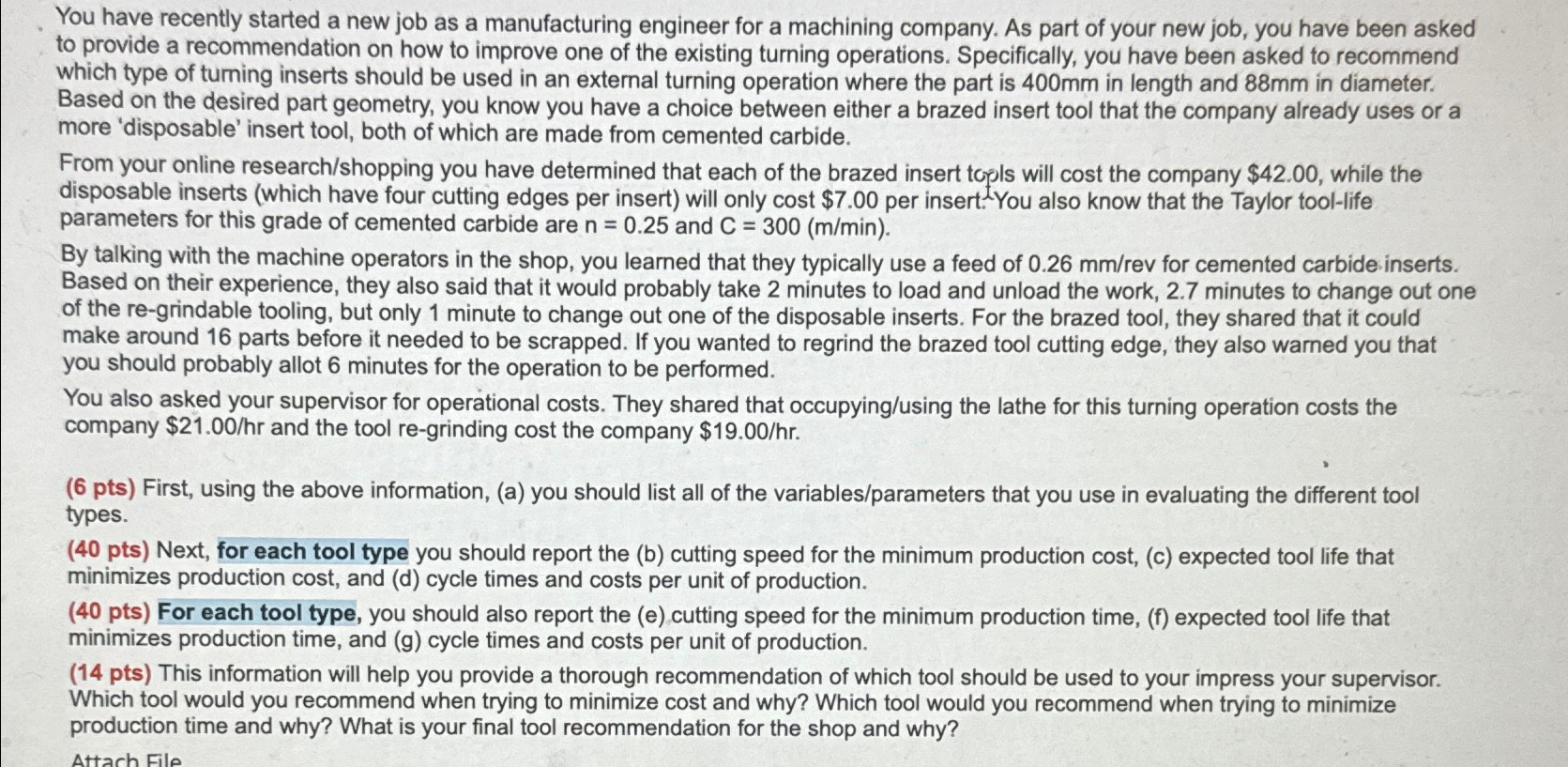

You have recently started a new job as a manufacturing engineer for a machining company. As part of your new job, you have been asked to provide a recommendation on how to improve one of the existing turning operations. Specifically, you have been asked to recommend which type of turning inserts should be used in an external turning operation where the part is in length and in diameter. Based on the desired part geometry, you know you have a choice between either a brazed insert tool that the company already uses or a more 'disposable' insert tool, both of which are made from cemented carbide.

From your online researchshopping you have determined that each of the brazed insert topls will cost the company $ while the disposable inserts which have four cutting edges per insert will only cost $ per insert. You also know that the Taylor toollife parameters for this grade of cemented carbide are and

By talking with the machine operators in the shop, you learned that they typically use a feed of for cemented carbide inserts. Based on their experience, they also said that it would probably take minutes to load and unload the work, minutes to change out one of the regrindable tooling, but only minute to change out one of the disposable inserts. For the brazed tool, they shared that it could make around parts before it needed to be scrapped. If you wanted to regrind the brazed tool cutting edge, they also warned you that you should probably allot minutes for the operation to be performed.

You also asked your supervisor for operational costs. They shared that occupyingusing the lathe for this turning operation costs the company $ and the tool regrinding cost the company $

pts First, using the above information, a you should list all of the variablesparameters that you use in evaluating the different tool types.

pts Next, for each tool type you should report the b cutting speed for the minimum production cost, c expected tool life that minimizes production cost, and d cycle times and costs per unit of production.

pts For each tool type, you should also report the e cutting speed for the minimum production time, f expected tool life that minimizes production time, and cycle times and costs per unit of production.

pts This information will help you provide a thorough recommendation of which tool should be used to your impress your supervisor. Which tool would you recommend when trying to minimize cost and why? Which tool would you recommend when trying to minimize production time and why? What is your final tool recommendation for the shop and why?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock