Question: You will create the solution of this exercise using Microsoft Powerpoint. You can watch the following video explaining how to use Powerpoint software to create

You will create the solution of this exercise using Microsoft Powerpoint. You can watch the following video explaining how to use Powerpoint software to create an ERD

Additional help on completing this data modeling exercise:

INFO***Additional help for the Data Modeling

Use the following information/business rules for the production order data modeling exercise:

Each product has a unique number and description.

Each production order has a unique number.

A product has MANY production order.

A production order is for ONE product.

A production order has MANY workstations and operations.

A product operation has a unique number and description.

Start and end date/times are for a specific combination of operation, workstation, and production order.

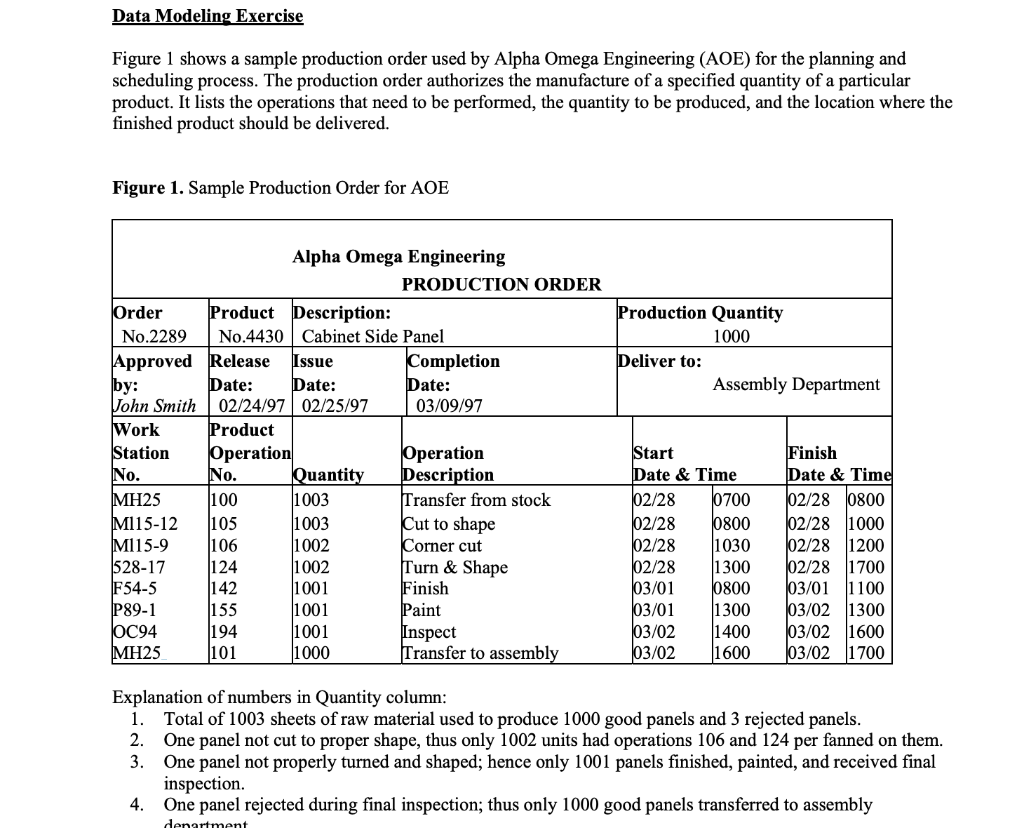

Data Modeling Exercise Figure 1 shows a sample production order used by Alpha Omega Engineering (AOE) for the planning and scheduling process. The production order authorizes the manufacture of a specified quantity of a particular product. It lists the operations that need to be performed, the quantity to be produced, and the location where the finished product should be delivered. Figure 1. Sample Production Order for AOE Production Quantity 1000 Deliver to: Assembly Department Alpha Omega Engineering PRODUCTION ORDER Order Product Description: No.2289 No.4430 Cabinet Side Panel Approved Release Issue Completion by: Date: Date: Date: John Smith 02/24/97 02/25/97 03/09/97 Work Product Station Operation Operation No. No. Quantity Description MH25 100 1003 Transfer from stock M115-12 105 1003 Cut to shape M115-9 106 1002 Corner cut 528-17 124 1002 Turn & Shape F54-5 142 1001 Finish P89-1 155 1001 Paint OC94 194 1001 Inspect MH25 101 1000 Transfer to assembly Start Date & Time 102/28 0700 02/28 10800 102/28 1030 02/28 1300 03/01 0800 03/01 11300 03/02 1400 03/02 1600 Finish Date & Time 02/28 0800 02/28 1000 02/28 1200 02/28 1700 03/01 1100 03/02 1300 03/02 1600 03/02 1700 Explanation of numbers in Quantity column: 1. Total of 1003 sheets of raw material used to produce 1000 good panels and 3 rejected panels. 2. One panel not cut to proper shape, thus only 1002 units had operations 106 and 124 per fanned on them. 3. One panel not properly turned and shaped; hence only 1001 panels finished, painted, and received final inspection 4. One panel rejected during final inspection; thus only 1000 good panels transferred to assembly denartment

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts