Question: YYour assignment is to recommend a production plan for the coming six months. Your supervisor has provided you with sales forecasts for each product for

YYour assignment is to recommend a production plan for the coming six months. Your supervisor has provided you with sales forecasts for each product for the next six months, and has asked you to use the forecast to generate a 6-month production plan, by month, that maximizes the companys profit and meets all forecasted requirements.

| Lawnmower | Leafblower | Snowblower | Generator | Total Sales | |

| Jan-20 | 1473 | 224 | 3009 | 393 | 5099 |

| Feb-20 | 2048 | 252 | 2198 | 308 | 4806 |

| Mar-20 | 2483 | 312 | 1851 | 138 | 4784 |

| Apr-20 | 3649 | 339 | 163 | 33 | 4184 |

| May-20 | 4183 | 407 | 125 | 135 | 4850 |

| Jun-20 | 3497 | 450 | 37 | 72 | 4056 |

You can hire new employees, use overtime, or level production throughout the year by overproducing in advance of demand and holding inventory (or a combination of some or all of these options). Hiring new employees comes at a one-time cost of $3,000. Overtime is paid at time-and-a-half (i.e., 150% of the normal labor rate for each category). Leveling production (i.e., spreading the annual production evenly over the year) will likely reduce the need for overtime and new hires, but increases inventory holding costs in months where production is greater than demand for that month. Assume inventory holding cost is only applied to excess inventory at the end of each month (i.e. inventory that remains AFTER demand has been met).

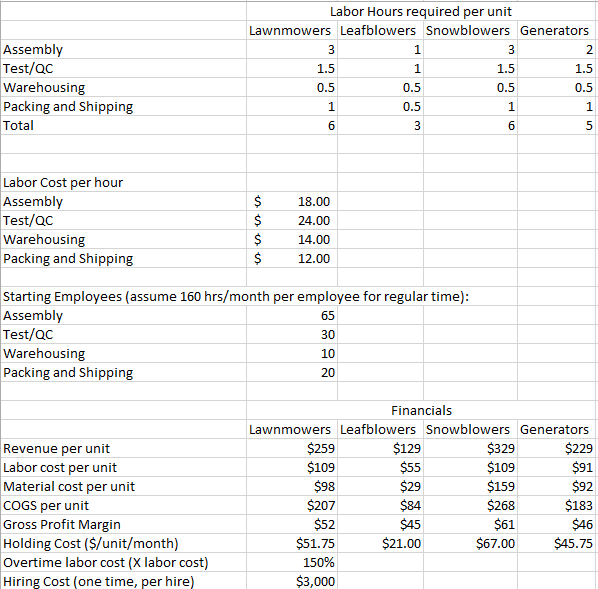

Assembly Test/QC Warehousing Packing and Shipping Total Labor Hours required per unit Lawnmowers Leafblowers Snowblowers Generators 3 1 3 2 1.5 1 1.5 1.5 0.5 0.5 0.5 0.5 1 0.5 1 1 6 3 6 5 18.00 Labor Cost per hour Assembly Test/QC Warehousing Packing and Shipping $ $ $ $ 24.00 14.00 12.00 Starting Employees (assume 160 hrs/month per employee for regular time): Assembly 65 Test/QC 30 Warehousing Packing and Shipping 10 20 Revenue per unit Labor cost per unit Material cost per unit COGS per unit Gross Profit Margin Holding Cost ($/unit/month) Overtime labor cost (X labor cost) Hiring Cost (one time, per hire) Financials Lawnmowers Leafblowers Snowblowers Generators $259 $129 $329 $229 $109 $55 $109 $91 $98 $29 $159 $92 $207 $84 $268 $183 $52 $45 $46 $51.75 $21.00 $67.00 $45.75 150% $3,000 $61 Assembly Test/QC Warehousing Packing and Shipping Total Labor Hours required per unit Lawnmowers Leafblowers Snowblowers Generators 3 1 3 2 1.5 1 1.5 1.5 0.5 0.5 0.5 0.5 1 0.5 1 1 6 3 6 5 18.00 Labor Cost per hour Assembly Test/QC Warehousing Packing and Shipping $ $ $ $ 24.00 14.00 12.00 Starting Employees (assume 160 hrs/month per employee for regular time): Assembly 65 Test/QC 30 Warehousing Packing and Shipping 10 20 Revenue per unit Labor cost per unit Material cost per unit COGS per unit Gross Profit Margin Holding Cost ($/unit/month) Overtime labor cost (X labor cost) Hiring Cost (one time, per hire) Financials Lawnmowers Leafblowers Snowblowers Generators $259 $129 $329 $229 $109 $55 $109 $91 $98 $29 $159 $92 $207 $84 $268 $183 $52 $45 $46 $51.75 $21.00 $67.00 $45.75 150% $3,000 $61

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts