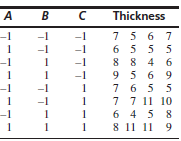

A process that manufactures vinyl for automobile seat covers was studied. Three factors were varied: the proportion

Question:

A process that manufactures vinyl for automobile seat covers was studied. Three factors were varied: the proportion of a certain plasticizer (A), the rate of extrusion (B), and the temperature of drying (C). The outcome of interest was the thickness of the vinyl (in mils). A 23 factorial design with four replicates was employed. The results are presented in the following table. (Based on the article ??Split-Plot Designs and Estimation Methods for Mixture Experiments with Process Variables,?? S. Kowalski, J. Cornell, and G. Vining, Technometrics, 2002:72??79.)

a. Estimate all main effects and interactions.

b. Construct an ANOVA table. You may give ranges for the P-values.

c. Is the additive model appropriate? Explain.

d. What conclusions about the factors can be drawn from these results?

Step by Step Answer: