Question: Engineers often use a Weibull failure time distribution for a weakest link product, i.e., a product consisting of multiple parts (e.g., roller bearings) that fails

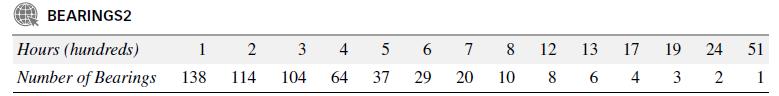

Engineers often use a Weibull failure time distribution for a “weakest link” product, i.e., a product consisting of multiple parts (e.g., roller bearings) that fails when the first part (or weakest link) fails. Nelson (Journal of Quality Technology, July 1985) applied the Weibull distribution to the life lengths of a sample of n = 138 roller bearings. The table at the top of the next page gives the number of bearings still in operation at the end of each 100-hour period until all bearings failed.

a. Use the method of least squares to estimate the Weibull parameters α and β.

b. Construct a 99% confidence interval for α. If you have access to a regression computer package, obtain a 99% confidence interval for β.

c. Estimate the reliability of the roller bearings at t = 300 hours.

d. Estimate the probability that a roller bearing will fail before 200 hours.

BEARINGS2 Hours (hundreds) 1 3 4 6. 7 12 13 17 19 24 51 Number of Bearings 138 114 104 64 37 29 20 10 8 6 4 3 2 1 8.

Step by Step Solution

3.40 Rating (159 Votes )

There are 3 Steps involved in it

a To estimate the Weibull parameters and we can use the method of least squares This involves findin... View full answer

Get step-by-step solutions from verified subject matter experts