An industrial facility needs a flow of 100 gpm of hot water at 180F, 50 psia. Two

Question:

An industrial facility needs a flow of 100 gpm of hot water at 180°F, 50 psia.

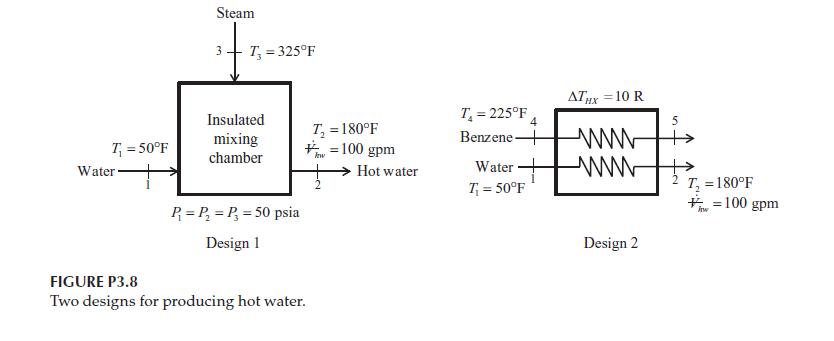

Two designs are being considered to make the hot water as shown in Figure P3.8. In Design 1, the hot water is produced by injecting steam into an insulated mixing chamber through which the water passes. The water enters the chamber at 50°F, 50 psia. Steam is injected into the chamber at 325°F, 50 psia. The hot water leaves at the required flow rate and temperature. For this system determine,

a. The mass flow rate of the water entering the chamber (lbm/h)

b. The mass flow rate of the steam injected into the chamber (lbm/h)

c. The exergy destruction rate in the chamber (Btu/h)

d. The exergetic efficiency of the chamber The second design, Design 2, the water is heated in a heat exchanger with a stream of hot liquid benzene that is available from another process in the facility.

The heat exchanger is a parallel flow configuration with a pinch point temperature difference of 10°R. The water enters the heat exchanger at 50°F and leaves at the required flow rate and temperature. The hot benzene enters the heat exchanger at 225°F. For this system determine,

e. The required mass flow rate of the benzene (lbm/h)

f. The exergy destruction rate in the heat exchanger

g. The exergetic efficiency of the heat exchanger

h. The effectiveness of the heat exchanger Assuming that the steam and hot benzene flows are readily available in the facility, discuss the tradeoffs between energy, exergy, and economics relating to these two designs.

Step by Step Answer:

Thermal Energy Systems Design And Analysis

ISBN: 9781138735897

2nd Edition

Authors: Steven G. Penoncello