Question: Process steam boilers often incorporate a continuous blowdown scheme to eliminate impurities that can accumulate over time. One way to accomplish this is shown in

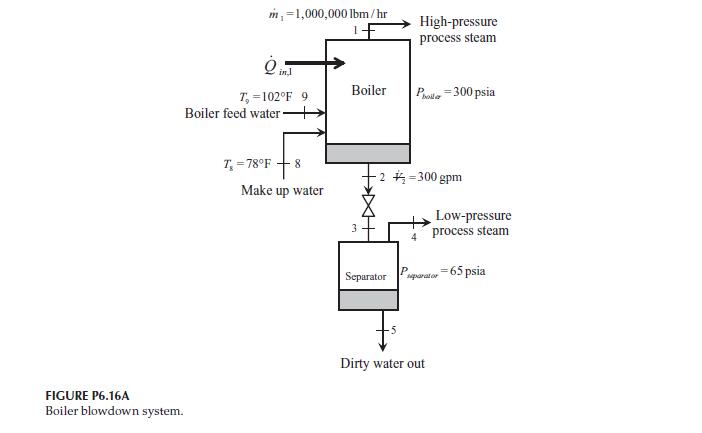

Process steam boilers often incorporate a continuous blowdown scheme to eliminate impurities that can accumulate over time. One way to accomplish this is shown in Figure P6.16A. In this system, the boiler is operating at 300 psia.

Saturated vapor steam leaves the boiler as the high-pressure process steam flow at a flow rate of 1,000,000 lbm/hr. Saturated liquid water, containing the impurities, exits the boiler at 300 gpm. The dirty water is then flashed into a separator through a valve. The separator pressure is 65 psia. Saturated vapor leaves the separator as the low-pressure process steam flow. The high pressure and lowpressure process steam flows make their way through the plant and eventually condense, combine and return to the boiler as a liquid boiler feed water at 102°F.

The saturated liquid at the separator exit is discarded. In order to maintain steady operation, makeup water must replace the discarded dirty water. This makeup water enters the boiler at 78°F. Simulate this system and determine the

a. Mass flow rate (lbm/hr) of the low-pressure process steam

b. Volumetric flow rate (gpm) of the discarded dirty water

c. Temperature of the discarded dirty water

d. Boiler heat transfer rate required to maintain continuous, steady state operation

(Btu/hr)

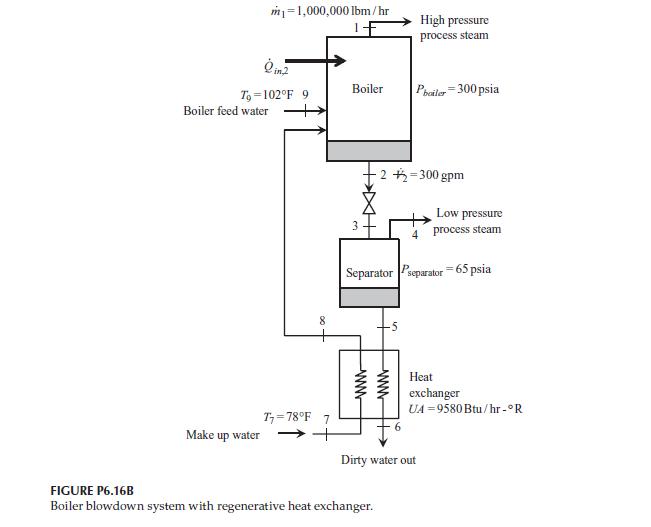

The result of your simulation should reveal that the temperature of the discarded dirty water is quite hot. It is proposed that this hot, dirty water be used to preheat the makeup water going into the boiler in an attempt to reduce fuel cost. This can be accomplished by adding a heat exchanger as shown in Figure P6.16B. It is reasonable to treat the heat exchanger as a counter flow regenerative heat exchanger. The mass flow rates of the water on each side are the same (the makeup water must replace the discarded dirty water). However, the heat capacities of the water on each side of the heat exchanger are slightly different. In reality, this difference is very small. Therefore, assuming that the thermal capacitance rates of each flow are equal is a reasonable approximation. A heat capacity value of 1.01 Btu/lbm-R is a reasonable estimate of cp for the water passing through the heat exchanger. The UA product of the heat exchanger is 9,580 Btu/hr-R. Simulate this modified system and determine the:

e. Temperature of the discarded dirty water

f. Temperature rise of the makeup water as it flows through the heat exchanger g. Boiler heat transfer rate required to maintain continuous, steady state operation (Btu/hr) This particular system operates continuously throughout the year. The heat transfer rate is provided by the combustion of natural gas that costs $0.70/therm.

(A therm is 100,000 Btu). Determine:

h. The annual energy cost savings realized by incorporating the regenerative heat exchanger as shown in Figure P6.16B.

i. If management requires a minimum rate of return of 25%, and the heat exchanger is expected to have a 50-year life, how much money can be spent on the heat exchanger? Does the heat exchanger appear to be a viable investment?

Investigate the effect of the separator pressure on the operating parameters of the boiler blowdown system described in Figure P6.16B. For this evaluation, vary the separator pressure from 20 psia to 100 psia and plot the following curves:

j. Annual energy cost savings as a function of the separator pressure k. Mass flow rate of the low-pressure process steam (lbm/hr) and the volumetric flow rate of the dirty water (gpm) leaving the separator as a function of the separator pressure.

l. Comment on the results of the parametric studies from Parts (j) and (k)

m, 1,000,000 lbm/hr 1 FIGURE P6.16A Boiler blowdown system. in T, 102F 9. = Boiler feed water T = 78F - 8 Make up water Boiler 3 Separator High-pressure process steam Pholle 300 psia -2-300 gpm 4 Low-pressure process steam sparator Dirty water out = 65 psia

Step by Step Solution

3.55 Rating (159 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts