Jindal Iron and Steel Co. Ltd (JISCO) is Indias largest integrated galvanizing facility accounting for 17 per

Question:

Jindal Iron and Steel Co. Ltd (JISCO) is India’s largest integrated galvanizing facility accounting for 17 per cent of the total galvanized iron production in the country. JISCO exports about 75 per cent of its production to over 45 countries. Its plants located in Vasind and Tarapur in Maharashtra boast of a capacity of GP/GC 710,000 tpa, HR 280,000 tpa, CR 750,000 tpa, respectively. The company’s chief strength has been its reliance on indigenous designs to implement projects at low costs.

Benchmarking at JISCO

In 1996, the top management of the company decided that to maintain its leadership among the secondary steel producing companies in India, it needed to compare its processes with the processes of another company, which was recognized and admired for its superior performance in that domain, world-wide. They chose British Steel that made a net profit of over one billion British pounds in 1995. JISCO requested British Steel Consultants (BSCOS), a British Steel Subsidiary to carry out the study over a period of six months beginning July 1996. BSCOS was selected primarily because their consultants were all ex-British Steel employees with decades of experience. They had consulted with almost all the large steel producing companies in the world. They had been also associated with Steel Authority of India (SAIL) for the last seven years and understood the culture and ways of working in the Indian context.

The benchmarks against which JISCO was assessed were two-fold:

1. JISCO’s major customers, both current and in the short to medium term, from within the market in India. The study focused on the quality of product and the quality of service after selling the product.

2. Those arising from outside India and representative of current trends in international standards.

The study focused more on the means of achieving product quality through the manufacturing process.

The Team

The team drawn up for this consisted of BSCOS consultants and JISCO personnel. Their activities included:

• Investigating and defining current performance within JISCO across a range of parameters.

• Establishing benchmarks of performance outside JISCO across the same range of parameters taking into account the particular plant configuration at JISCO along with its capabilities.

• Identifying current constraints to achieve the benchmarks as well as actions necessary to overcome those constraints.

The benchmarking study was named Project PACE, where PACE was an acronym for Planned Action for Continued Excellence. The study was carried out under three main heads—marketing, plant performance and organization and manpower competence. The scope and methodology followed for each is given below:

Marketing

The current and future market requirements with respect to quality and service were studied, thus providing a target against which output performance of the manufacturing plants could be assessed. This also included the current JISCO marketing organization and its procedures and practices.

Plant Performance

The operational and engineering performances of the manufacturing plants located at Tarapur and Vasind were studied with specific reference to how services provided from outside these departments affected their performance.

Organizational and Manpower Competence

The study covered the organizational structure and its effectiveness in ensuring plant performance and customer satisfaction, current manning, levels of competence and the methods used to ensure that agreed levels of competence were met and constantly improved upon.

There was an assessment also of the manner in which day-to-day activities were monitored and controlled and the way in which decisions were communicated.

Extensive discussions held with customers at their workplace, employees at different levels within the organization, comparison within India and abroad of competitors’ delivery performances, yields, complaint-handling procedures, credit policies, dependence on information technology and a whole host of other benchmarks showed that JISCO needed to do a lot to meet its intention of being “one of the most preferred employers by the year 2000.”

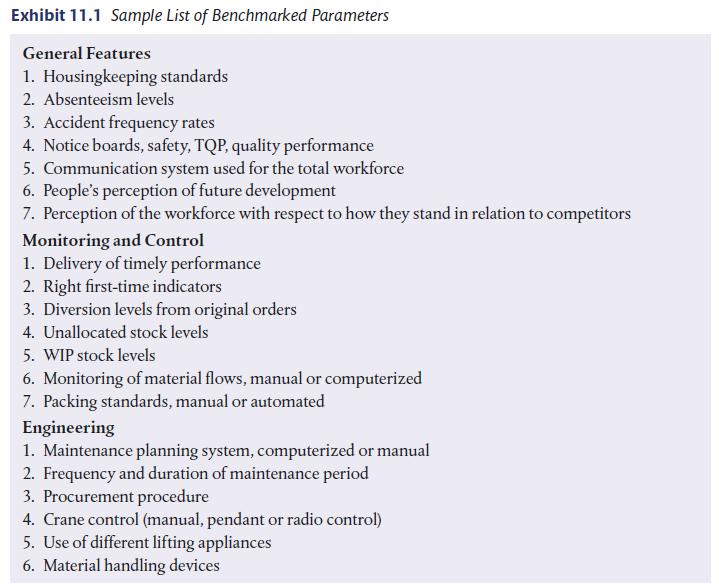

Exhibit 11.1 provides a sample list of benchmarked parameters at JISCO.

Some of the recommendations on which action plans were developed and implemented were:

• Extending the role of the marketing department from its current focus on selling to a range of activities that would increase its understanding of the market and the capabilities of the company to anticipate and fulfill market demands more effectively.

• Encouraging the closer involvement of the producing units in support of the marketing effort and customer service and thus increasing their own commitment to meet customer requirements.

• Establishing mechanisms whereby failures to meet market requirements could be immediately dealt with and solutions could be built into everyday practice and sustained.

• Installing a culture of attention to detail, thus making a shift from the “detection” of failure to the “prevention” of failure.

• Building on current HRD initiatives in ways which impinged more directly on improvements in individual, team, departmental and company performance, thus changing the focus to one of improving actual competence to do a job and not just developing knowledge about a job.

Benefits of Benchmarking

According to Raman Madhok, Group Vice President—HRD and OD, JISCO, “Without being really conscious of it, we’ve all done benchmarking. We saw someone who was better organized or got more work done, or could run faster, bowl a quicker delivery, score more runs or play tennis better. And we wondered, how do they do that? Benchmarking is a demanding process but the results are well worth the effort.”

In spite of very difficult market conditions, the benchmarking effort enabled JISCO to perform better in terms of both sales as well as profitability compared to its competitors in the steel industry.

Question For Discussion

1. Why did JISCO decide to go in for benchmarking and with whom?

2. What was the scope and methodology followed by JISCO?

3. Comment on the statement “Benchmarking is a demanding process; however, the results are well worth the effort.”

Step by Step Answer: