Traditional quality control methods identify variation as the enemy of ensuring quality. However, the control of variation

Question:

Traditional quality control methods identify variation as the enemy of ensuring quality.

However, the control of variation by itself can never achieve the remarkably low nonconformance rates of world-

class quality leaders. The best methods for controlling variation, mistakes and complexity are each forms of mistake proofing. Using these mistake-proofing techniques, virtually every mistake and non-

conformance can be controlled at a fraction of the cost of traditional quality control methods.

The FZU-48 fuze initiator (for the FMU-l39 bomb fuze) programme in the Tactical Electronics Division (TED) of Motorola moved quickly and smoothly from the design stage to the full-scale high-volume production stage by utilizing statistical process control (spc )

techniques.

Virtually all phases of product manufacturing (design, assembly, tooling, machines, test equipment and inspection) used SPC and problem-solving techniques (PST). The result was a system capable of delivering excellent product quality and achieving a high volume production output.

All machinery, tooling and fixtures were carefully designed with a zero defect approach.

A team of engineers trained in SPC carefully reviewed the design prints in a brainstorming/

failure analysis and correction mode to minimize design flaws during production. After the machines, test equipment, tools and other peripherals arrived, they underwent carefully planned machine capability studies.

The machine capability studies comprised two phases. First, a capability index (Cpk)

and a capability potential (Cp) were calculated for all critical variables followed by tests for statistical control. Next, reduction of variation was performed when the capability index failed to meet the planned target Cpk index of greater than 1.0 (factored by a four sigma spread). During the reduction of variation, variables contributing to variation were identified and either removed or reduced to a controllable level.

The capability studies helped to predict the performance of the equipment with a level of certainty and to collectively determine whether the process had sufficiently low variability to meet process specifications. It also served to uncover areas of potential problems before production and encouraged efforts to prevent production of non-conformance products.

Seventy per cent of the machines (test equipment, tools, etc.) had a capability index Cpk higher than 2.0 (planned goal Cpk) and the other 30 per cent exceeded a Cpk of 1.0. The Final Lanyard Pin Press experienced seven cycles of machine capability studies and redesign before it was considered unsuitable for production and replaced by a new machine.

During the various stages of production, many problems arose and were aggressively corrected utilizing PST and SPC techniques. PST techniques included brainstorming sessions, cause-and-effect diagrams and Pareto diagrams. SPC techniques included variable search and statistically designed single-factor and full factorial experiments.

Ishikawa (cause-and-effect) diagrams, design of experiments (DOE) and brainstorming were used to solve complex problems such as the epoxy leakage through the end cap towers,

reducing the defective rate from 68 per cent to less than 0.1 per cent. The use of DOE was also effective in correcting the problem of high shearing force for lanyard separation, which failed to shear at a force of 148 + 20 lbs-f. A two by three (three factors, two levels) full factorial experiment was designed and conducted yielding accountability for 96 per cent of the variation. The standard deviation of the shearing force prior to experimentation was 34 and was successfully reduced to 3.3.

After the completion of the first 115 deliverable FZU-48 units, an unforeseen design flaw resulted in the failure of the First Article Acceptance Test. Aggressive utilization of PST and DOE techniques by a team comprising design, manufacturing, quality assurance and test engineers corrected the problem.

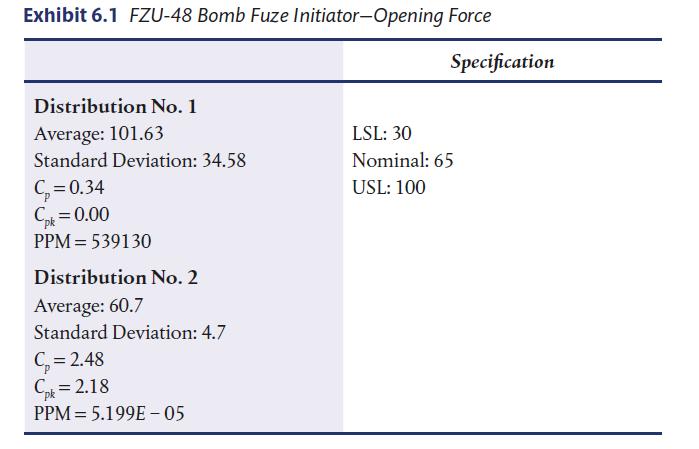

In a period of five weeks, 14 consecutive statistically designed experiments were conducted, leading to product design changes and reduction of product performance variability. The standard deviation of the cover opening force of the unit prior to experimentation was 34.58. It was reduced to 4.70, thereby achieving a Cpk equal to 2.20 and exceeding Motorola’s Six Sigma design objective (see Exhibit 6.1).

Since production began in early August 1987, the FZU-48 programme has increased its production by ten times, from 50 units per day initially to 550 units per day. During this period, eight consecutive lot acceptance tests (LATs) have been conducted and passed. Of all the units tested during the LATs, one unit failed. That unit was later found to have a piece part out of tolerance that caused the failure.

The team of SPC experts responsible for applying the SPC techniques consisted of Adi K. Bhote, TED SPC coordinator for the Manufacturing Board Assembly Area; Jim Blanden, TED Manufacturing SPC specialist; and Mario Perez-Wilson, Divisional SPC manager, Small Signal & Sensor Products Division, Semiconductor Products Sector, and former SPC coordinator for the FZU-48 and FMU-139 programmes.

Contributing their engineering expertise and support were Jim Gardner, senior test equipment engineer, Ron Meyer, lead design engineer, and Pete Rendek, lead design engineer. Management commitment and support to implement SPC from the design stages was provided by Kevin Mulroy, then a quality assurance team member and Ray Beliveau, manufacturing team member.

“The FZU-48 programme is probably the first programme in Motorola that utilized SPC techniques from the very beginning. This Programme has been quoted by the customer as being their first programme to go from design to full-scale production in a fast and smooth manner. The major ingredient for this success has been the implementation of SPC,” Mario said. No blueprint exists for the successful implementation of SPC in a production system.

However, the SPC techniques used on the FZU-48 programmed can facilitate a smooth transition from design to full-scale production on other programmes if they are performed as early as possible prior to production.

On the FZU-48 programme, potential problems were detected using machine/process capability studies, statistically quantified using descriptive statistics and probabilities and statistically corrected with statistically designed experiments. After implementation, the corrections were statistically validated. The end result was a high-quality output.

Question For Discussion

1. Why was SPC introduced in the FZO-48 fuze initiator programme?

2. How did process capability studies help the division?

3. Comment on the results given in Exhibit 6.1.

Step by Step Answer: