Question: A major problem in packaging very large-scale integrated (VLSI) circuits concerns cooling of the circuit elements. The problem results from increasing levels of power dissipation

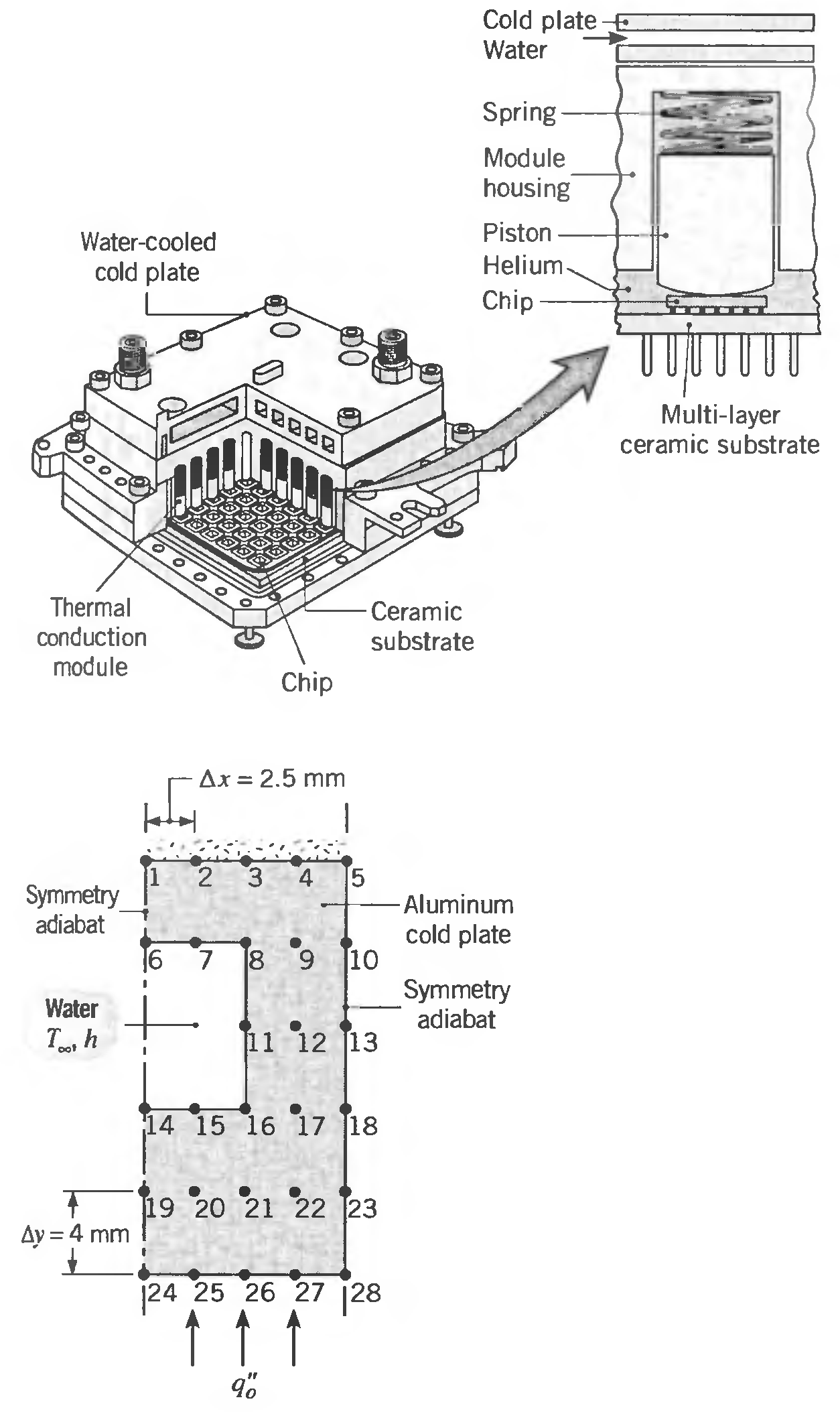

A major problem in packaging very large-scale integrated (VLSI) circuits concerns cooling of the circuit elements. The problem results from increasing levels of power dissipation within a chip, as well as from packing chips closer together in a module. A novel technique for cooling multichip modules has been developed by IBM. Termed the thermal conduction module (TCM), the chips are soldered to a multilayer ceramic substrate, and heat dissipated in each chip is conducted through a spring-loaded aluminum piston to a water-cooled cold plate.

(a) Consider a cold plate fabricated from aluminum (k = 190 W/m ∙ K) with regularly spaced rectangular channels through which the water is passed. Under normal operation, power dissipation within the chips results in a uniform heat flux of q"0 = 105 W/m2 at the base of the cold plate, while water flow provides a temperature of T∞ = 15°C and a convection coefficient of h = 5000 W/m2 ∙ K within the channels. We are interested in obtaining the steady-state temperature distribution within the cold plate, and from symmetry considerations, we may confine our attention to the prescribed nodal network. Assuming the top surface of the cold plate to be well insulated, determine the nodal temperatures.

(b) Although there is interest in operating at higher power levels, system reliability considerations dictate that the maximum cold plate temperature must not exceed 40°C. Using the prescribed cold plate geometry and nodal network, assess the effect of changes in operating or design conditions intended to increase the operating heat flux q"0. Estimate the upper limit for the heat flux.

Cold plate Water Spring Module housing Piston Water-cooled Helium- cold plate Chip - Multi-layer ceramic substrate Thermal conduction module -Ceramic substrate Chip Ax = 2.5 mm 3. 4 Symmetry adiabat Aluminum cold plate |8 9 10 Symmetry adiabat Water T, h 11 12 13 14 15 16 17 18 19 20 21 22 23 Ay = 4 mm 24 25 26 27 j28

Step by Step Solution

3.50 Rating (167 Votes )

There are 3 Steps involved in it

KNOWN Nodal network and boundary conditions for a watercooled cold plate FIND a Steadystate temperature distribution for prescribed conditions b Means by which operation may be extended to larger heat ... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

8-E-M-E-H-M-T (355).docx

120 KBs Word File