Question: A manufacturing services provider of complex optical and electromechanical components seeks to gain efficiency in its jobshop scheduling decision because the current shopfloor operations suffer

A manufacturing services provider of complex optical and electromechanical components seeks to gain efficiency in its jobshop scheduling decision because the current shopfloor operations suffer from a few issues:

• There is no system to record when the workinprocess (WIP) items actually arrive at or leave operating workstations and how long those WIPs actually stay at each workstation.

• The current system cannot monitor or keep track of the movement of each WIP in the production line in real time.

As a result, the company is facing two main issues at this production line: high backlogs and high costs of overtime to meet the demand. In addition, the upstream cannot respond to unexpected incidents such as changes in demand or material shortages quickly enough and revise schedules in a costeffective manner. The company is considering implementing RFID on a production line. However, the company does not know if going to this major expense of adding RFID chips on production boxes, installing RFID readers throughout the production line, and of course, the systems to process this information will result in any real gains. So one question is to explore any new production scheduling changes that may result by investing in RFID infrastructure.

Methodology

Because exploring the introduction of any new system in the physical production system can be extremely expensive or even disruptive, a discrete event simulation model was developed to examine how tracking and traceability through RFID can facilitate jobshop production scheduling activities. A visibilitybased scheduling (VBS) rule that utilizes the realtime traceability systems to track those WIPs, parts and components, and raw materials in shopfloor operations was proposed.

A simulation approach was applied to examine the benefit of the VBS rule against the classical scheduling rules: the firstinfirstout and earliest due date dispatching rules. The simulation model was developed using Simio. Simio is a 3@D simulation modeling software package that employs an objectoriented approach to modeling and has recently been used in many areas such as factories, supply chains, healthcare, airports, and service systems.

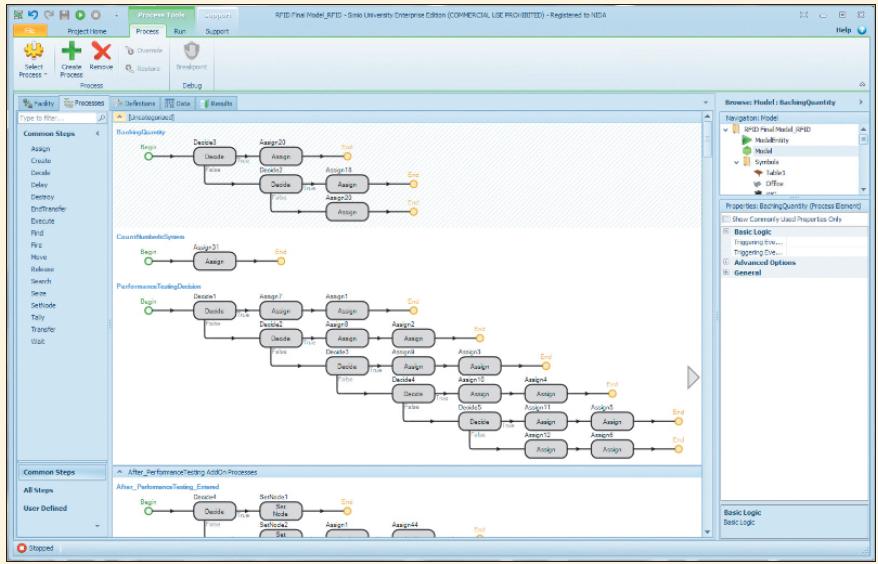

Figure 8.13 presents a screenshot of the Simio interface panel of this production line. The parameter estimates used for the initial state in the simulation model include weekly demand and forecast, process flow, number of workstations, number of shopfloor operators, and operating time at each workstation. In addition, parameters of some of the input data such as RFID tagging time, information retrieving time, or system updating time are estimated from a pilot study and from the subject matter experts. Figure 8.14 presents the process view of the simulation model where specific simulation commands are implemented and coded.

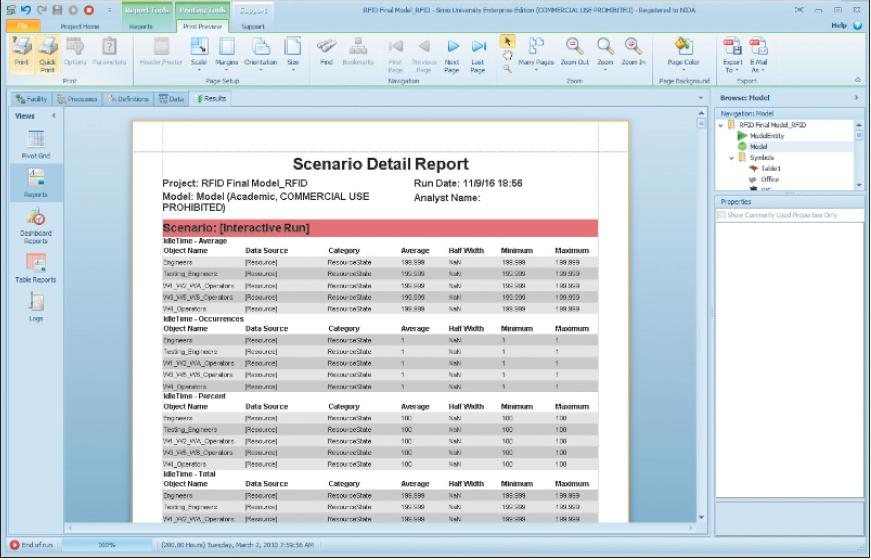

Figures 8.15 and 8.16 present the standard report view and pivot grid report of the simulation model.

The standard report and pivot grid format provide a very quick method to find specific statistical results such as average, percent, total, maximum, or minimum values of variables assigned and captured as an output of the simulation model.

Results

The results of the simulation suggest that an RFIDbased scheduling rule generates better performance compared to traditional scheduling rules with regard to processing time, production time, resource utilization, backlogs, and productivity. The company can take these productivity gains and perform cost/ benefit analyses in making the final investment decisions.

Figure 8.14

Figure 18.15

Figure 18.16

Questions for Discussion

1. In situations such as what this case depicts, what other approaches can one take to analyze investment decisions?

2. How would one save time if an RFID chip can tell the exact location of a product in process?

3. Research to learn about the applications of RFID sensors in other settings. Which one do you find most interesting?

CHOO Dear Quee Conne Separator Re Libraries Standard Library Source 9 de k Besdoce Traf Connect Puh Test AM Conveyor Run Status Labe Status Pe Floor Laberou Gauge Shtune G Attached Anton Proces Flow Library Standard Libr [Project Library] Moddaly Def Factity de Antration Stack Sutton NID Wy F16 Apply Imported Simbol Symbo Symbol Project Symbo Leart Feat Sin Symbo Support Data Entry Point W2 Material Inspection PCBA X Al Aditrol tetton Symbol W1 KittingProcess PCBA ProductionLine (10) Adolymbole Engineers ingegneers, and Operators APES Node RES-Senty (COMMERCIAL USE PROSA SA PF 14 PF 11 WA1 SUPOR Syed Server! Server2 Cetur TRAS Decoration W3 WS Wo Operators Inspection Metbe Habes Flow W3 FailedTest PCBA Tools Browse Model: W Negeto Model FDF Mod RFD Mod Symb Office Propertes: Wattingcerve So Commy Used P Process Logic City Inital Capety Bang Ruk Ranang Dynamic So... Non Tranefe... 00 Pro Type HU heal 10 Process Logic Pro Logic Specfic Tin Suspend Processing Peg Te Tagging Time Off Rule Buller Capacities Reliability Logic State Assignments Secondary Resources Financials Add-On Process Triggers Advanced Options Log Resource... Pie DisplayName Trafer-In C... Def Transfer-Out... Doble 8.0 Expected 0...0.0 General Anation P YD 10 Lungest Value First ModelEntity Familylle.

Step by Step Solution

3.40 Rating (159 Votes )

There are 3 Steps involved in it

1 There are several alternative approaches to analyze investment decisions in situations like the one described in the case a CostBenefit Analysis CBA Conduct a comprehensive costbenefit analysis to e... View full answer

Get step-by-step solutions from verified subject matter experts