Consider an aluminum fabrication plant with 400 employees that runs on three shifts for a total of

Question:

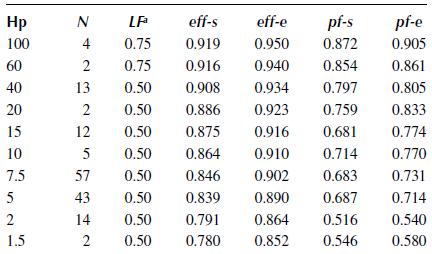

Consider an aluminum fabrication plant with 400 employees that runs on three shifts for a total of 8,760 hours per year. The company spent $1.1 million in electric energy bills last year. The plant uses numerous motors to drive process-related equipment such as shell presses and compound presses. Determine if it is cost-effective to replace the existing motors with high-efficient motors under the following three rate structures:

For all the rates, the utility company charges the facility an average cost of electricity, without demand, of $0.05/kWh. The demand charges are:

a. Rate 1: 7.02/kVA

b. Rate 2: $5.00/kW (billed demand)

c. Rate 3: $5.00/kW plus $0.75 for excess KVAR above 6 percent of real demand The motors that will be replaced are listed below.

Step by Step Answer:

Energy Audit Of Building Systems An Engineering Approach

ISBN: 9780367820466

3rd Edition

Authors: Moncef Krarti