A catalytic process was designed to make 150 metric tons per year of product with a net

Question:

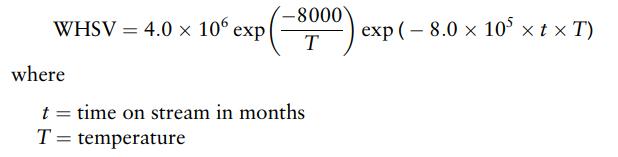

A catalytic process was designed to make 150 metric tons per year of product with a net profit of $0.25/lb of product. The catalyst for the process costs $10/lb and it takes 2 months to shut down the process, empty the old catalyst, reload fresh catalyst, and restart the process. The feed and product recovery and purification sections can be pushed to make as much as 120% of design basis capacity. The reactor section is sized with sufficient catalyst to make 100% of design basis when operated with fresh catalyst at 5008F. The reactor can be operated at temperatures only up to 6208F, for safety reasons. The reactor weight hourly space velocity (lb of product per hour per lb of catalyst) is given by the equation

Find the optimal temperature versus time profile for the reactor and determine how long the process should be operated before the catalyst is changed out.

Step by Step Answer: