A process design for the disproportionation of toluene to benzene and the xylene isomers is being completed.

Question:

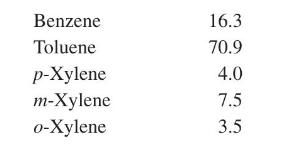

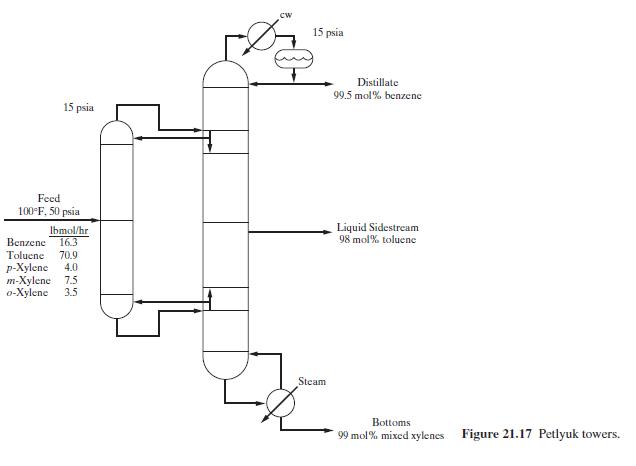

A process design for the disproportionation of toluene to benzene and the xylene isomers is being completed. Your assistance is needed on the design of the liquid separation section. It has been established that the feed to this section is at \(100^{\circ} \mathrm{F}\) and \(50 \mathrm{psia}\) with the following flows in \(\mathrm{lbmol} / \mathrm{hr}\) :

From this feed, it is desired to produce \(99.5 \mathrm{~mol} \%\) benzene, \(98 \mathrm{~mol} \%\) toluene for recycle, and \(99 \mathrm{~mol} \%\) mixed xylenes by distillation in two

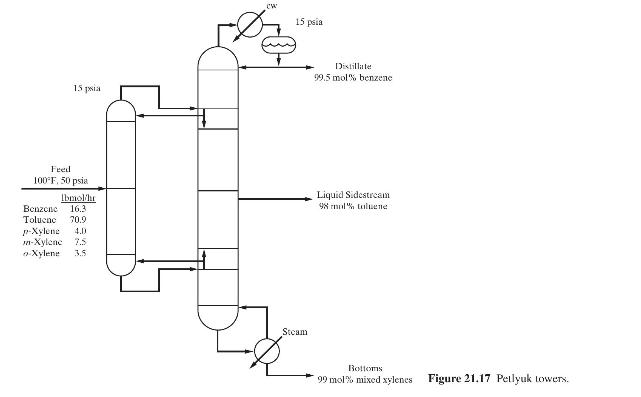

columns. The assigned plant operators have informed us that they prefer the direct sequence of two columns. However, because of the high percentage of toluene in the feed, a thermally coupled system shown in Figure 21.17, known as Petlyuk towers after the Russian inventor, may be a less expensive alternative.

Please prepare process designs for these two alternatives, together with estimates of capital and operating costs, and indicate whether the

Petlyuk towers are attractive. The plant-operating factor is assumed to be \(95 \%\). The following data and instructions are provided for the design of the towers:

(a) Determine optimal feed preheat using the bottoms product where applicable.

(b) Determine optimal reflux ratios.

(c) Set a pressure of 15 psia at the top of each column, assuming no pressure drop through the condenser. Determine column bottom pressure drop from tray pressure drops.

(d) Use standard sieve trays. Overall tray efficiency is estimated to be \(90 \%\) for operation at \(85 \%\) of flooding.

(e) Determine column diameters to the next increment of \(0.5 \mathrm{ft}\) for each section and swedge the columns, when section diameters differ by more than \(0.5 \mathrm{ft}\).

(f) Use reflux subcooled to \(120^{\circ} \mathrm{F}\) from each condenser.

(g) Standard materials of construction, for example, carbon steel, can be used. (h) Minimum shell thickness for columns and vessels is as follows:

\(1 / 4 \mathrm{in}\). for diameters less than \(4 \mathrm{ft}\)

\(5 / 16 \mathrm{in}\). for diameters from 4 to \(5.5 \mathrm{ft}\)

\(3 / 8\) in. for diameters from 6 to \(7.5 \mathrm{ft}\)

\(7 / 16\) in. for diameters from 8 to \(11.5 \mathrm{ft}\)

\(1 / 2\) in. for diameters from 10 to \(12 \mathrm{ft}\)

(i) Provide horizontal reflux drums that can hold liquid reflux and distillate for \(5 \mathrm{~min}\) at half full.

(j) Include all necessary liquid pumps with spares.

Figure 21.17:-

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng