In a process for the manufacture of (mathrm{C}) from (mathrm{A}) and (mathrm{B}), streams of (mathrm{A}) and (mathrm{B})

Question:

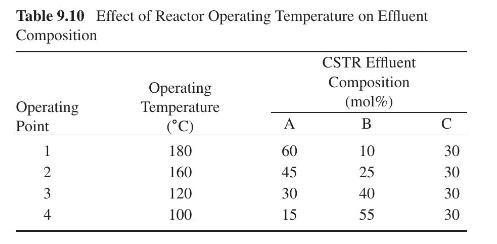

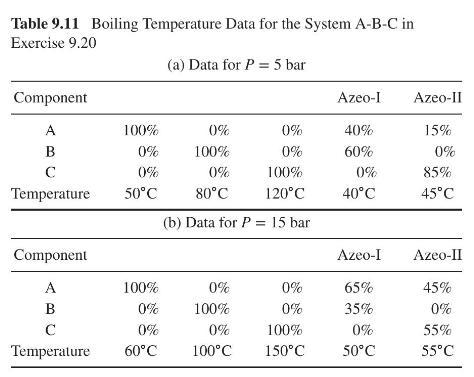

In a process for the manufacture of \(\mathrm{C}\) from \(\mathrm{A}\) and \(\mathrm{B}\), streams of \(\mathrm{A}\) and \(\mathrm{B}\) are fed to a CSTR, where they undergo reversible reaction to the product: \(\mathrm{A}+\mathrm{B} \rightleftharpoons \mathrm{C}\). Because the reaction is highly exothermic, the reactor needs to be cooled. And because the reaction is reversible, all three species are present in the reactor effluent in compositions according to the operating temperature of the CSTR as presented in Table 9.10. The CSTR effluent is fed to a distillation column, designed to separate the product \(\mathrm{C}\) from the reagents \(\mathrm{A}\) and \(\mathrm{B}\), which are recycled to the reactor.

In addition to selecting the most appropriate operating temperature for the CSTR, you must also design a separation system to produce highly pure C (at least \(99 \mathrm{~mol} \%\) ) consisting of as few distillation towers as possible, each having only two product streams (distillate and bottoms), with each column operating either at 5 or 15 bar. Boiling temperature data for the system A-B-C are provided in Table 9.11 for the two operating pressures. You are asked to keep plant operating costs to a minimum!

Data From Table 9.10 and 9.11:-

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng