When the third tPA cultivator in Example 2.3 is added to the cultivators in Example 7.6, as

Question:

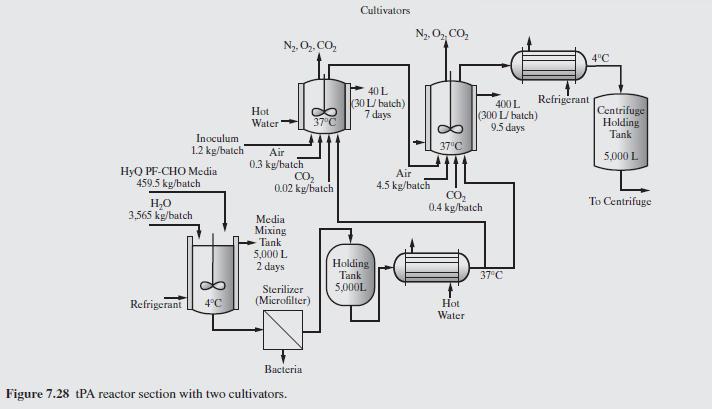

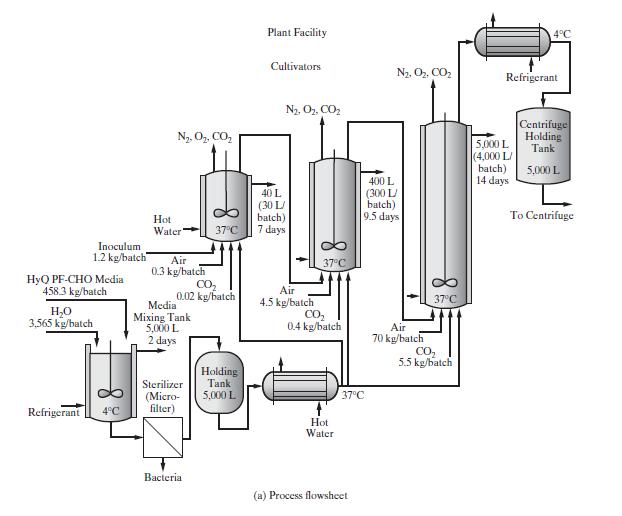

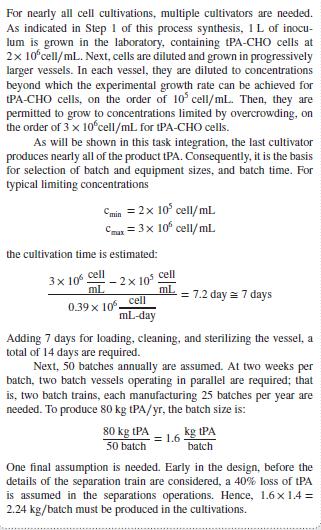

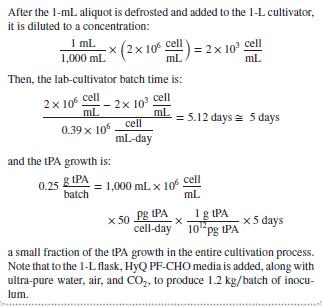

When the third tPA cultivator in Example 2.3 is added to the cultivators in Example 7.6, as shown in Figure 7.27a, a significant time strain is placed on the process because the combined feed, cultivation, harvest, and cleaning time in this largest vessel is long and rigid. Consequently, the remainder of the process is designed to keep this cultivator in constant use, so as to maximize the yearly output of product. Note that, in many cases, when an equipment item causes a bottleneck, a duplicate is installed so as to reduce the cycle time.

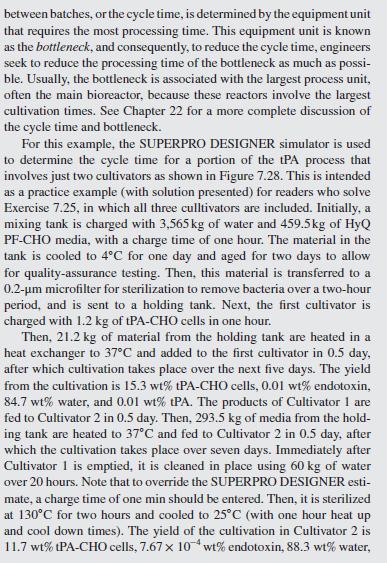

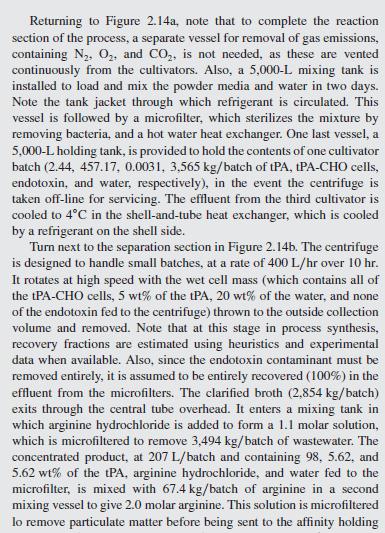

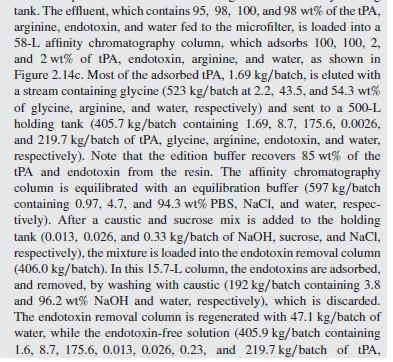

For this exercise, the third cultivator is added to the simulation in Example 7.6 with the specifications for the mixer, filter, holding tank, heat exchanger 1, and first two cultivators identical to those in Example 7.6. After the cultivation is completed in Cultivator 2, its cell mass is transferred as inoculum to Cultivator 3 over 0.5 day. Then, the remaining media from the mixing tank is heated to \(37^{\circ} \mathrm{C}\) and added over 1.5 days after which cultivation takes place over eight days. Immediately after the transfer from Cultivator 2 to Cultivator 3, Cultivator 2 is cleaned in place using \(600 \mathrm{~kg}\) of water over \(20 \mathrm{hr}\). The yield of the cultivation in Cultivator 3 is \(11.4 \mathrm{wt} \%\) tPA-CHO cells, \(7.7 \times 10^{-5} \mathrm{wt} \%\) endotoxin, \(88.9 \mathrm{wt} \%\) water, and \(0.0559 \mathrm{wt} \% \mathrm{tPA}\). When the cultivation is completed in Cultivator 3, its contents are cooled in a heat exchanger to \(4^{\circ} \mathrm{C}\) and transferred to the centrifuge holding tank over one day, and Cultivator 3 is cleaned using \(600 \mathrm{~kg}\) of water over \(67 \mathrm{hr}\) and sterilized using the procedure for Cultivators 1 and 2.

To eliminate an undesirable bottleneck(s), and reduce the cycle time to 14 days (total operation time of Cultivator 3), it may be necessary to add an equipment units(s).

Print and submit the text recipes and three-batch schedules for both the original process and the modified process, if debottlenecking is necessary, as prepared by SUPERPRO DESIGNER.

Data From Example 7.6:-

Figure 7.27(a):-

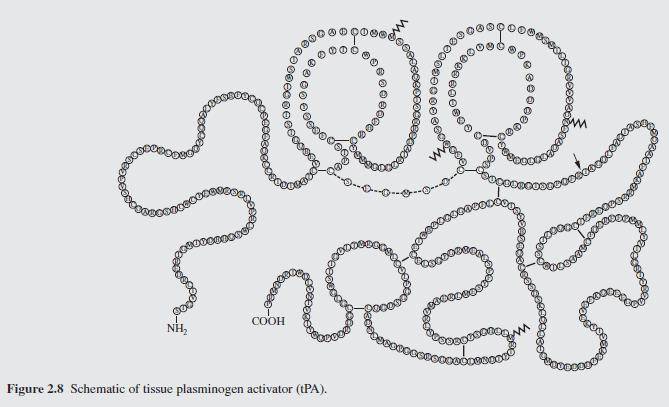

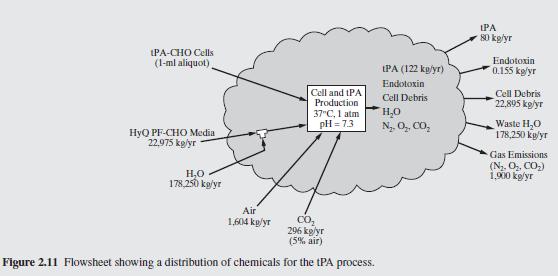

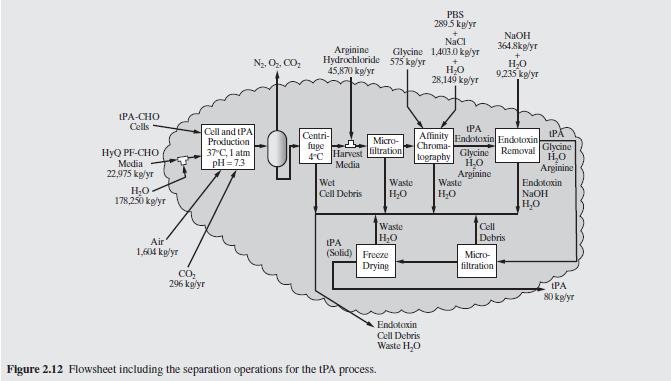

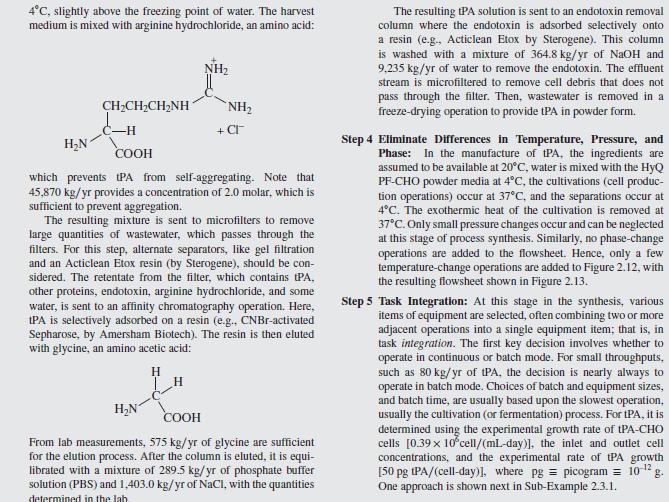

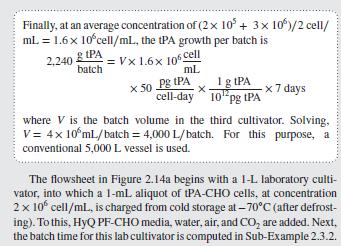

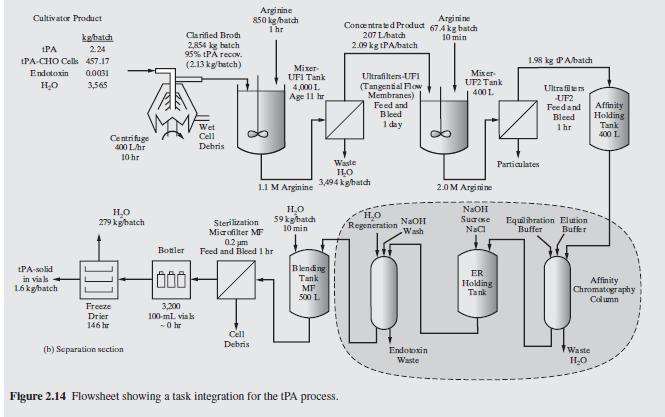

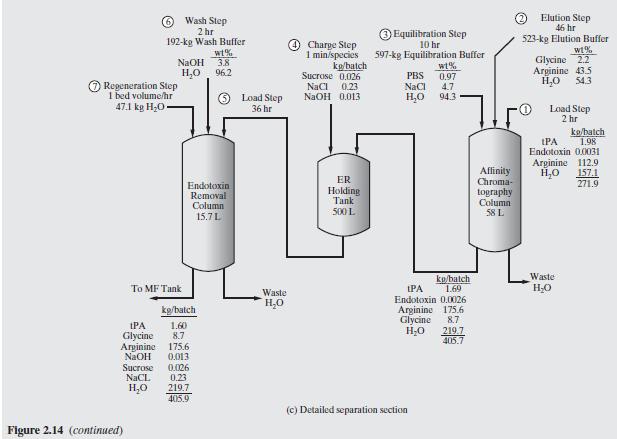

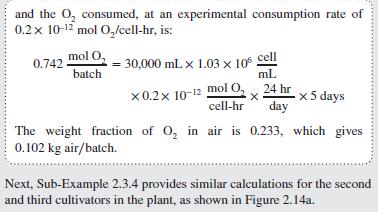

Data From Example 2.3:-

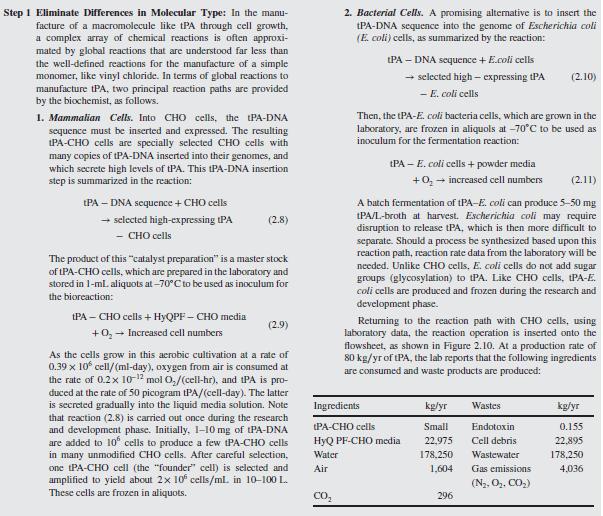

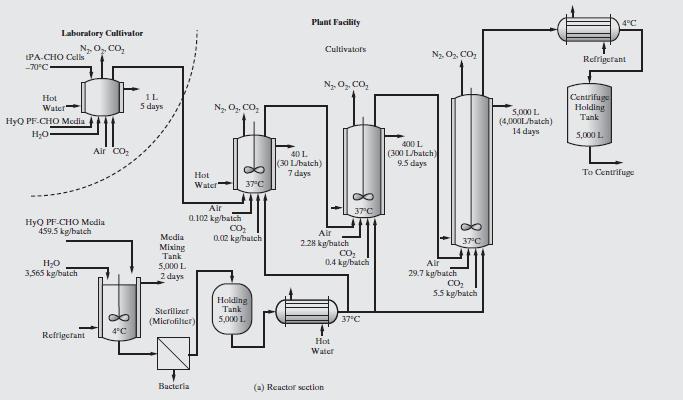

Data From Sub Example 2.3.1:-

Data From Sub Example 2.3.2:-

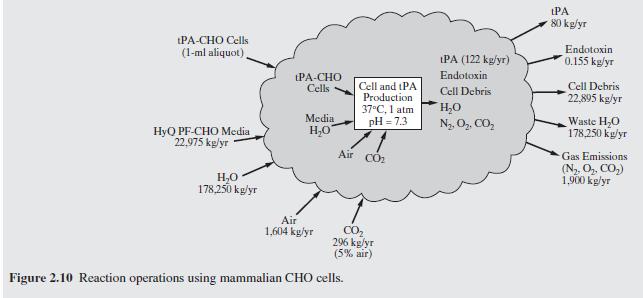

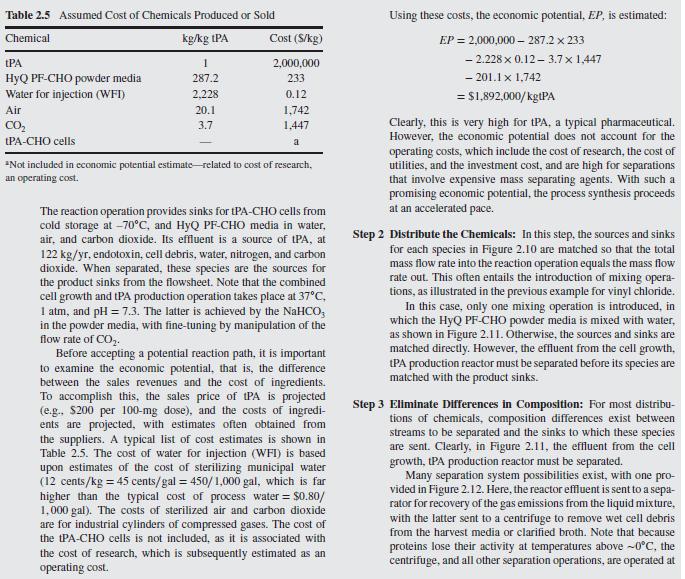

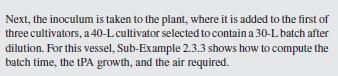

Data From Sub Example 2.3.3:-

Data From Sub Example 2.3.4:-

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng