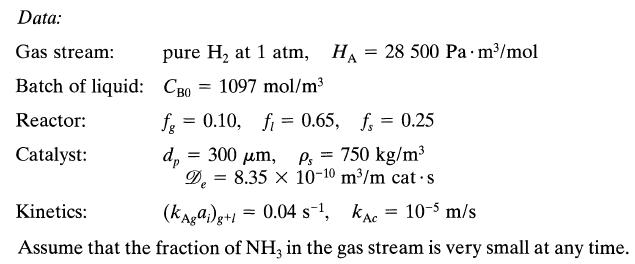

Consider a different design to effect the hydrogenation of the previous problem, one which uses a long,

Question:

Consider a different design to effect the hydrogenation of the previous problem, one which uses a long, narrow bubble column of semi suspended 3-mm catalyst particles (fs, = 0.4, fl = 0.5, fg = 0.1). The batch of liquid aniline is circulated through an external heat exchanger (volume of liquid in the loop outside the reactor equals the total volume of the reactor), and hydrogen is bubbled through the column. Find the time needed for 90% conversion of aniline in this unit.![]()

All other values not mentioned here remain unchanged from the previous problem.

Data from previous problem

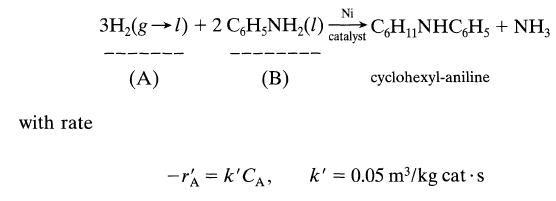

Aniline is to be hydrogenated in a three-phase fluidized bed of porous clay particles impregnated with nickel catalyst. The well-agitated batch of liquid is kept at 130°C by heat exchanger tubes passing through the fluidized bed, and by bubbling hydroAniline is to be hydrogenated in a three-phase fluidized bed of porous clay particles impregnated with nickel catalyst. The well-agitated batch of liquid is kept at 130°C by heat exchanger tubes passing through the fluidized bed, and by bubbling hydro

Find the time needed for 90% conversion of this batch of aniline.

Step by Step Answer: