Question: An article in Solid State Technology (Orthogonal Design for Process Optimization and Its Application in Plasma Etching, May 1987, pp. 127-132) describes the application of

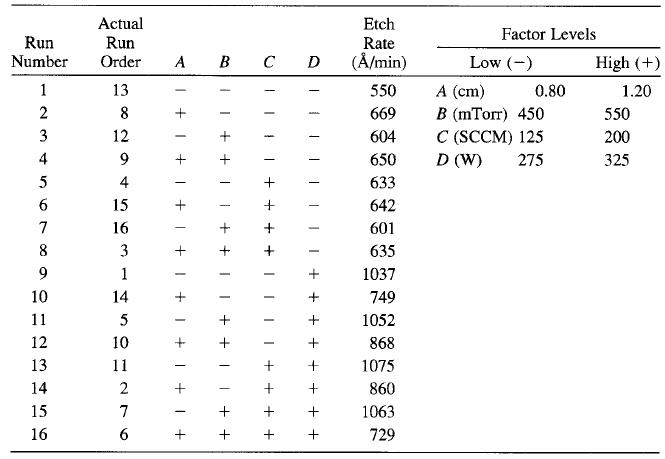

An article in Solid State Technology ("Orthogonal Design for Process Optimization and Its Application in Plasma Etching," May 1987, pp. 127-132) describes the application of factorial designs in developing a nitride etch process on a single-wafer plasma etcher. The process uses C2F6 as the reactant gas. Four factors are of interest: anode—cathode gap (A), pressure in the reactor chamber (B), C2F6 gas flow (C), and power applied to the cathode (D). The response variable of interest is the etch rate for silicon nitride. A single replicate of a 24 design is run, and the data are shown below:

(a) Estimate the factor effects. Consider a normal probability plot of the factor effects. Which effects appear large?

(b) Conduct an analysis of variance to confirm your findings for part (a).

(c) What is the regression model relating etch rate to the significant process variables?

(d) Analyze the residuals from this experiment. Comment on the model's adequacy.

(e) If not all the factors are important, project the 24 design into a 2k design with k < 4 and conduct the analysis of variance.

(f) Draw graphs to interpret any significant interactions.

(g) Plot the residuals versus the actual run order. What problems might be revealed by this plot?

Actual Etch Factor Levels Run Run Order Rate Number A B C D (/min) Low (-) High (+) 1 13 550 A (cm) 0.80 1.20 2 8 669 B (mTorr) 450 550 - 3 12 604 C (SCCM) 125 200 4 650 D (W) 275 325 5 4 633 15 642 7 16 601 3 635 9. 1 1037 10 14 749 11 5 1052 12 10 868 13 11 1075 14 2 860 15 7 1063 16 6 + + + 729 + + +

Step by Step Solution

3.38 Rating (164 Votes )

There are 3 Steps involved in it

a Estimate the factor effects Consider a normal probability plot of the factor effects Which effects appear large 1 Calculate the effect of each factor Well use the contrast method to determine the fa... View full answer

Get step-by-step solutions from verified subject matter experts