Question: In a biofuels plant distillation tower, a single-pass shell- and-tube heat exchanger is used to condense saturated ethanol vapor to saturated ethanol liquid using water

a. What is the mass flow rate of cooling water required?

b. What is the log-mean temperature driving force in the condenser?

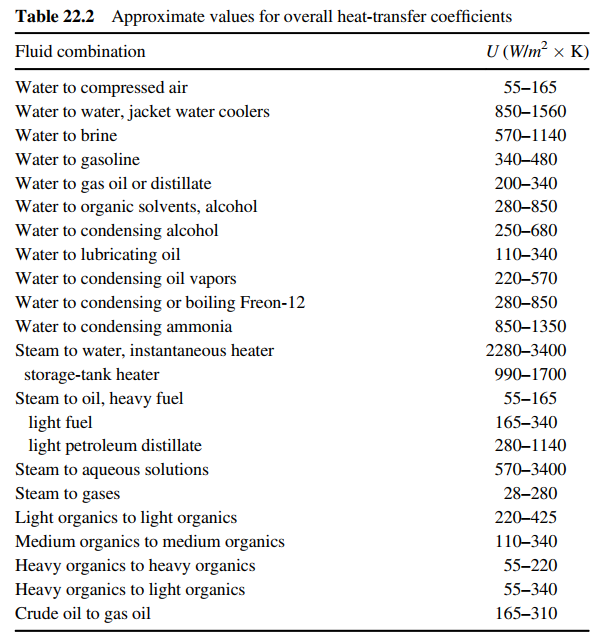

c. If the overall heat-transfer coefficient is 250 W/m2 · K (Table 22.2), what is the required heat-transfer area?

d. If the cooling water outlet temperature is allowed to increase by stepping down the cooling water flow rate, what happens to the required heat-transfer area?

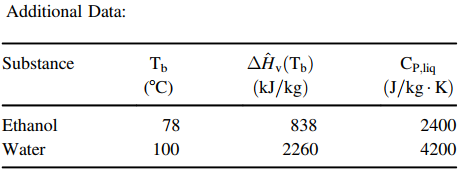

Additional Data: Substance (T ) (kJ/kg) (C) Cp,jiq (J/kg K) Ethanol Water 838 2400 4200 78 100 2260 Table 22.2 Approximate values for overall heat-transfer coefficients Fluid combination U (W/m x K) Water to compressed air 55165 Water to water, jacket water coolers 8501560 Water to brine 5701140 Water to gasoline 340-480 Water to gas oil or distillate Water to organic solvents, alcohol Water to condensing alcohol Water to lubricating oil Water to condensing oil vapors 200340 280-850 250680 110340 220-570 Water to condensing or boiling Freon-12 Water to condensing ammonia 280850 8501350 Steam to water, instantaneous heater 22803400 storage-tank heater Steam to oil, heavy fuel 9901700 55-165 light fuel light petroleum distillate Steam to aqueous solutions Steam to gases 165340 2801140 5703400 28280 220425 Light organics to light organics Medium organics to medium organics 110340 Heavy organics to heavy organics Heavy organics to light organics Crude oil to gas oil 55-220 55-340 165310

Step by Step Solution

3.46 Rating (166 Votes )

There are 3 Steps involved in it

Hot fluid ethanol shell side B Cold fluid water tube side ... View full answer

Get step-by-step solutions from verified subject matter experts