A liquid food product is processed in a continuousflow sterilizer. The liquid enters the sterilizer at a

Question:

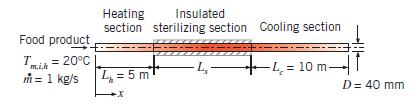

A liquid food product is processed in a continuousflow sterilizer. The liquid enters the sterilizer at a temperature and flow rate of Tm,i,h = 20°C, m = 1 kg/s, respectively. A time-at-temperature constraint requires that the product be held at a mean temperature of Tm = 90°C for 10 s to kill bacteria, while a second constraint is that the local product temperature cannot exceed Tmax = 230°C in order to preserve a pleasing taste. The sterilizer consists of an upstream, Lh = 5m heating section characterized by a uniform heat flux, an intermediate insulated sterilizing section, and a downstream cooling section of length Lc = 10 m. The cooling section is composed of an uninsulated tube exposed to a quiescent environment at T∞ = 20°C. The thin-walled tubing is of diameter D = 40 mm. Food properties are similar to those of liquid water at T = 330 K.

(a) What heat flux is required in the heating section to ensure a maximum mean product temperature of Tm = 90°C?

(b) Determine the location and value of the maximum local product temperature. Is the second constraint satisfied?

(c) Determine the minimum length of the sterilizing section needed to satisfy the time-at-temperature constraint.

(d) Sketch the axial distribution of the mean, surface, and centerline temperatures from the inlet of the heating section to the outlet of the cooling section.

Step by Step Answer:

Fundamentals Of Heat And Mass Transfer

ISBN: 9780470501979

7th Edition

Authors: Theodore L. Bergman, Adrienne S. Lavine, Frank P. Incropera, David P. DeWitt