Design the battery for an industrial application that requires 10-kWh energy in 1.5 h for a dc

Question:

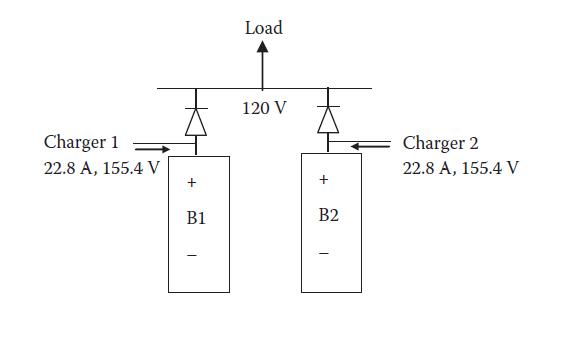

Design the battery for an industrial application that requires 10-kWh energy in 1.5 h for a dc load at 120 V three times daily for 250 days every year. The battery must be completely recharged in 2.0 h after each discharge. Use Li-ion cells in this example, but the design process will be applicable to other electro chemistries as well. Use the following Li-ion cell parameters: average discharge voltage 3.6 V, average charge voltage 4.2 V, c/d ratio 1.1, trickle charge rate C/100, and average life 2000 cycles at 100% DoD. For the purpose of reliability, design the battery with two strings in parallel. To avoid one string charging the other, place an isolation diode with 1-V drop in the discharge path of each string as shown in the figure below. Assume that each cell has 10-mΩ internal resistance at the operating temperature. If the battery must last five calendar years before replacement, determine:

(1) The number of cells in series in each parallel string, (2) The discharge current,

(3) The ampere-hour ratings of each cell,

(4) The charge current,

(5) The charge voltage, and

(6) The trickle charges current.

Step by Step Answer:

Introduction To Electrical Power And Power Electronics

ISBN: 9781466556607

1st Edition

Authors: Mukund R. Patel