Question: The chart below allows exploration of components for composites with desired combinations of thermal conductivity and expansion, using light alloy or polymer matrices. Three possible

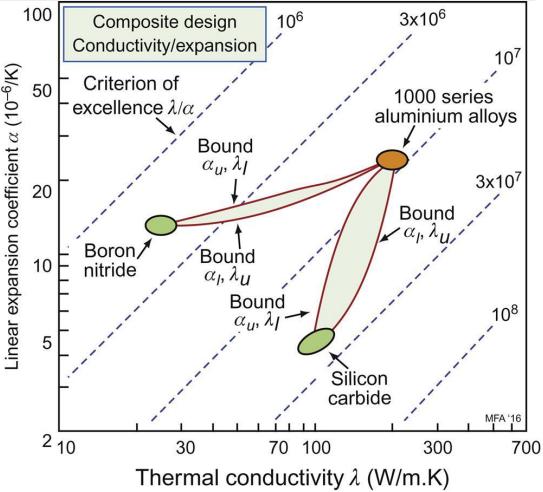

The chart below allows exploration of components for composites with desired combinations of thermal conductivity and expansion, using light alloy or polymer matrices. Three possible matrices -aluminium, magnesium and titanium - are shown in red. The materials shown in green are available as fibres (f), whiskers (w) and particles (p). A construction like that of Fig. 12.14 allows the potential of any given matrix-reinforcement combination to be assessed. One criterion of excellence (the index for materials to minimize thermal distortion, \(\lambda / \alpha\) ) is shown; it increases in value towards the bottom right. Use the chart to compare the performance of a magnesium AZ63 alloy-matrix composite reinforced with

(a) alloy steel fibres,

(b) silicon carbide fibres, \(\mathrm{SiC}\)

(c) diamond-structured carbon particles. Keep it simple to calculate the upper and lower bounds for \(\alpha\) and \(\lambda\) at a volume fraction of \(f=0.5\) and plot these points. Then sketch curves linking matrix to reinforcement to pass through the outermost of the points. In making your judgement, assume that \(f=0.5\) is the maximum practical reinforcement level.

Data From Fig, 12.14

100 Composite design Conductivity/expansion 106 3x106 107 50 50 20 20 Linear expansion coefficient a (10-6/K) Criterion of excellence /, Bound 4:21 1000 series aluminium alloys Boron Bound 10 nitride Bound 3x107 Bound 108 Silicon carbide MFA 16 210 30 70 100 300 700 Thermal conductivity 1 (W/m.K)

Step by Step Solution

3.36 Rating (152 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts