KMC Airlines was established 40 years ago and currently operates a small fleet of planes that fly

Question:

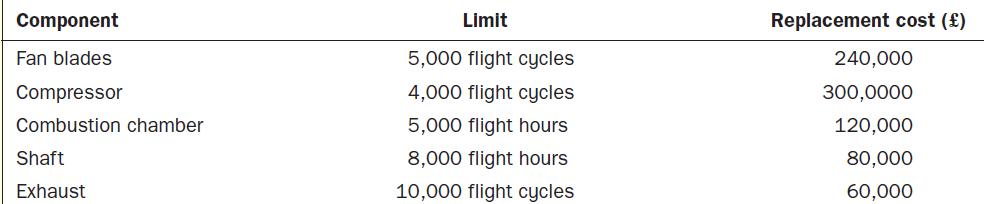

KMC Airlines was established 40 years ago and currently operates a small fleet of planes that fly to various cities across Europe from their base in the East Midlands. Whilst they are not a market leader in the airline industry, they have successfully generated healthy profits and have previously focused on customer service and continuous improvements to current operations rather than expansion into new locations. They are considering the use of a newly developed engine that will replace the current engines in their fleet. The new engine will meet new legislation on emissions and noise. The components of the engine have to be replaced when a particular number of cycles or hours has been reached (a cycle is a take off and landing). The new engine has the following major components and limits:

KMC currently operates approximately 100 cycles and 200 flight hours per month. Each plane (and therefore each engine) operates for an average of 25 days each month. The airline has traditionally used a ‘cost per flight hour’ in its cost calculations.

Required

1. How long will an engine operate for in KMC before it needs to have a component replaced?

2. If KMC use activity-based costing and split the costs into hourly and cyclic costs, what would the costs be for the engine parts?

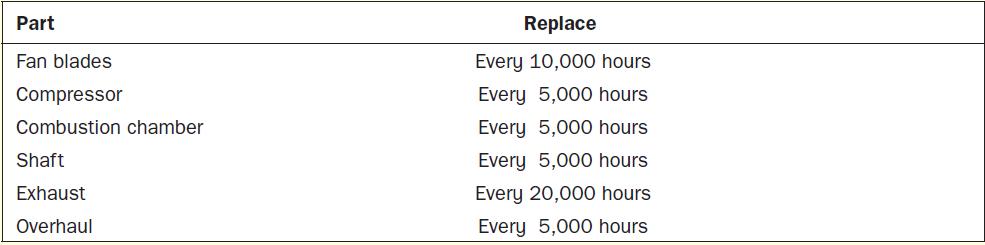

3. What is the cost per hour for the engine components, based on 200 hours and 100 cycles per month? Each time an engine has an overhaul, there is a £200,000 cost for transport, handling and labour, as well as the cost of the life-limited components. Engine maintenance must be scheduled to maximize the time between engine overhaul, without exceeding any of the life limits on components. The maintenance manager said: ‘The compressor and the shaft should be replaced at the first visit. Otherwise we will have to have a second overhaul just 3,000 hours later.’ The parts that have life remaining could be sold, but KMC does not include this in their cost calculations. The schedule for maintenance for KMC is as follows:

4. What is the cost per hour for the components and overhaul based on the above maintenance schedule?

5. The maintenance schedule above assumes that the ratio of hours to cycles remains the same. Flights are currently around 2 hours in length. What will happen if the flight length (and therefore the ratio of hours to cycles) changes?

6. KMC is investigating operating on a new route which will be short flights. The number of hours flown in a month won’t change, but the number of cycles is likely to double. How long will an engine operate for in KMC on the new route before it needs to have a component replaced?

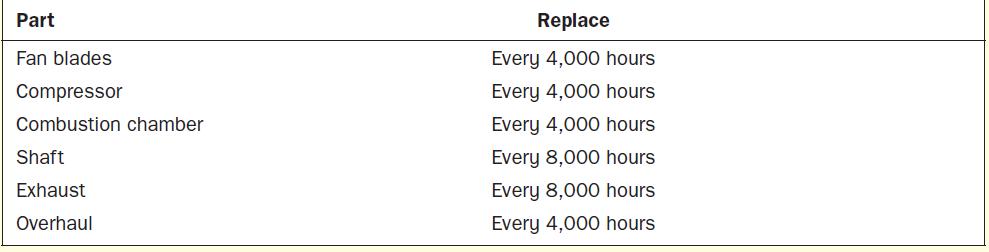

7. When considering the maintenance schedule for the engines operating on the proposed new route, the maintenance manager said: ‘Needing an overhaul after just 4,000 hours of flying will still cost £200,000. And it means that we will have to replace several parts at that overhaul.’ The new maintenance schedule for the engines on the new route is as follows:

What is the revised cost per hour for the engines based on the new maintenance schedule?

8. KMC decide that the new engine will be cost-efficient but only if it is used on the existing routes with the ratio of 2:1 hours to cycles. Using the maintenance schedule in Requirement 3, what is the cost per hour and the cost per cycle for the engine?

Step by Step Answer:

Management Accounting

ISBN: 9780077185534

6th Edition

Authors: Will Seal, Carsten Rohde, Ray Garrison, Eric Noreen