The manufacture of appliances can produce hazardous waste. New manufacturing facilities and processes can eliminate or greatly

Question:

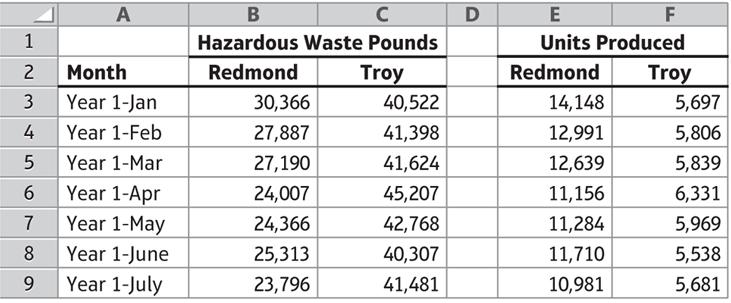

The manufacture of appliances can produce hazardous waste. New manufacturing facilities and processes can eliminate or greatly decrease the amount of hazardous waste generated. In addition, products themselves can be reengineered to lessen hazardous waste generation. The Newton Appliance Company has a goal to eliminate the generation of hazardous materials in its manufacturing process within the next 10 years. Newton has been tracking the pounds of hazardous waste it has generated for the past few years. The company has two factories: the original factory in Redmond and a new factory in Troy that opened two years ago to meet increasing demand. In the 12 months after the new factory in Troy opened, Newton gradually replaced its aging manufacturing equipment in its Redmond factory with new state-of-the-art equipment. To follow is a partial listing of the pounds of hazardous waste generated each month over the past two years as well as the number of units produced at both factories during those same months. Access the Excel file online in the MyLab Accounting exercise to complete the requirements for this exercise.

Requirements

1. Create a clustered column chart for the months and hazard waste pounds by factory.

2. Create a clustered column chart for the months and units produced by factory.

3. Copy and paste Column A to Column H so that you have the columns to the left of the hazardous waste pounds per unit calculation.

4. Calculate hazardous waste pounds per unit produced for both Redmond (Column I) and Troy (Column J) for each of the rows of data.

5. Create a clustered column chart based on the data in Columns H, I, and J.

6. What conclusions can you draw from the column charts you have created?

Step by Step Answer: