Mark Sumansky owns and manages Green Grass, a lawn-care service located in Kitchener, Ont. His customers include

Question:

Mark employs five crews, with three to five workers each, to cut grass during the spring and summer months. A crew normally works 10-hour days and can average cutting about 25 normal-size lawns of less than a quarter-hectare (half-acre) each day. A crew will normally use one heavy-duty, wide-cut riding mower, a regular power mower, and trimming equipment. When a crew descends on a lawn, the normal procedure is for one person to mow the main part of the lawn with the riding mower, one or two people to trim, and one person to use the smaller mower to cut areas the riding mower cannot reach. Crews move very fast, and they can often cut a lawn in 15 minutes.

Unfortunately, although speed is an essential component in the profitability of Green Grass, it can also contribute to quality problems. In haste, a mower might cut flowers, shrubs, or border plants, nick and scrape trees, €œskin€ spots on the lawn creating bare spots, trim too close, scrape house paint, cut or disfigure house trim, or destroy toys and lawn furniture, among other things. When these problems occur on a too-frequent basis, a customer cancels the service, and Mark has a difficult time getting a replacement customer. In addition, he gets most of his subscriptions based on word-of-mouth recommendations and retention of previous customers who are satisfied with his service. As such, quality is a very important factor in his business.

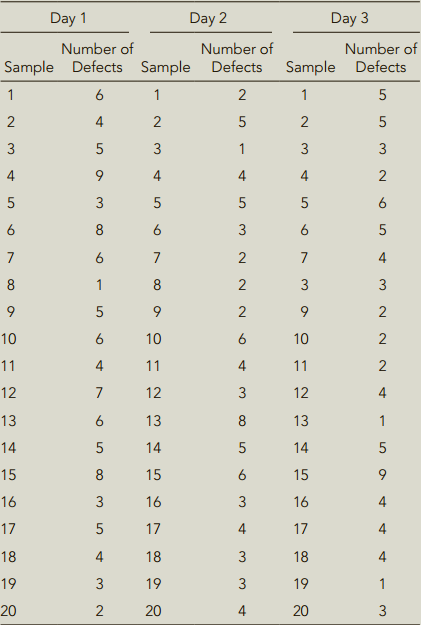

To improve the quality of his lawn-care service, Mark decides to use a process control chart to monitor defects. He hires Lisa Anderson to follow the teams and check lawns for defects after the mowers have left. A defect is any abnormal or abusive condition created by the crew, including those items just mentioned. It is not possible for Lisa to inspect the more than 100 lawns the service cuts daily, so she randomly picks a sample of 20 lawns each day and counts the number of defects she sees at each lawn. She also makes a note of each defect so that if there is a problem, the cause can easily be determined. In most cases the defects are caused by haste, but some defects can be caused by faulty equipment or by a crew member using a poor technique or not being attentive.

Over a three-day period, Lisa accumulated the following data on defects:

Develop a process control chart for Green Grass to monitor the quality of its lawn service using 2σ limits. Describe any other quality-control or quality-management procedures you think Green Grass might employ to improve the quality of its service.

Step by Step Answer:

Operations Management Creating Value Along the Supply Chain

ISBN: 978-1118301173

1st Canadian Edition

Authors: Roberta S. Russell, Bernard W. Taylor, Ignacio Castillo, Navneet Vidyarthi