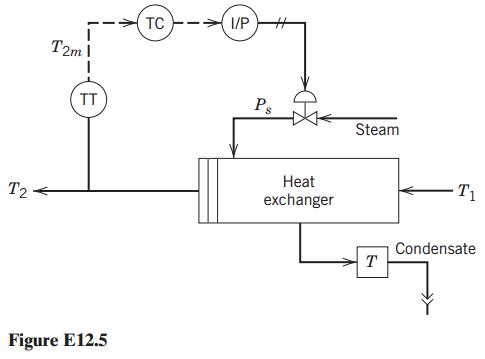

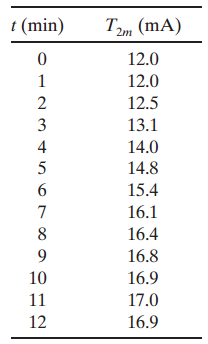

Question: A process stream is heated using a shell and tube heat exchanger. The exit temperature is controlled by adjusting the steam control valve shown in

were obtained. At the nominal conditions, the control valve and current-to-pressure transducers have gains of Kv = 0.9 psi/psi and KIP = 0.75 psi/mA, respectively. Deter-mine appropriate PID controller settings using the following approaches:

(a) Internal Model Control (select a reasonable value of Ï„c)

(b) AMIGO (with β = 1 and γ = 0)

(c) ITAE (disturbance) Which controller is the most aggressive?

- I/P C mi Ps TT Steam eat T1 T2 exchanger Condensate Figure E12.5 t (min) 2m 12.0 12.0 12.5 3 13.1 4 14.0 5 14.8 6. 15.4 16.1 16.4 9. 16.8 10 16.9 11 17.0 12 16.9

Step by Step Solution

3.39 Rating (183 Votes )

There are 3 Steps involved in it

Assume that the process can be modeled adequately by the firstorderplustime delaymode... View full answer

Get step-by-step solutions from verified subject matter experts