Question: 1 3 . 8 - 7 . The MFG Company produces a certain subassembly in each of two separate plants. These subassemblies are then brought

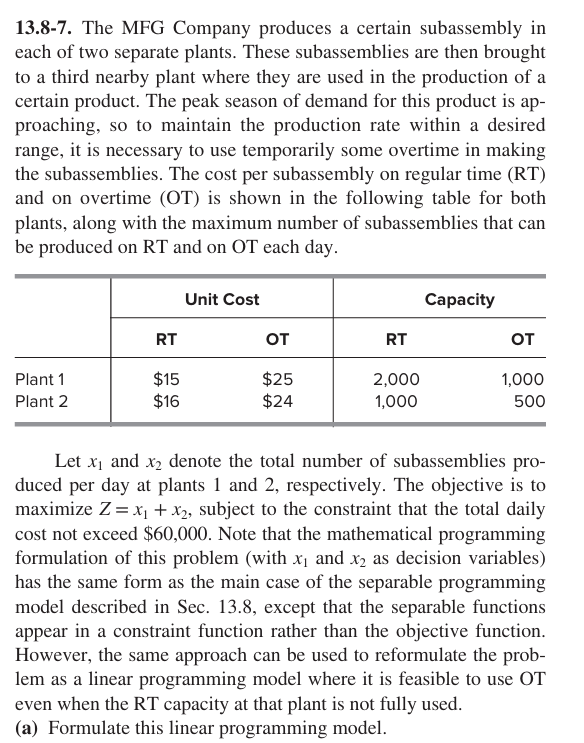

The MFG Company produces a certain subassembly in each of two separate plants. These subassemblies are then brought to a third nearby plant where they are used in the production of a certain product. The peak season of demand for this product is approaching, so to maintain the production rate within a desired range, it is necessary to use temporarily some overtime in making the subassemblies. The cost per subassembly on regular time RT and on overtime OT is shown in the following table for both plants, along with the maximum number of subassemblies that can be produced on RT and on OT each day.

Let x and x denote the total number of subassemblies produced per day at plants and respectively. The objective is to maximize Zxx subject to the constraint that the total daily cost not exceed $ Note that the mathematical programming formulation of this problem with x and x as decision variables has the same form as the main case of the separable programming model described in Sec. except that the separable functions appear in a constraint function rather than the objective function. However, the same approach can be used to reformulate the problem as a linear programming model where it is feasible to use OT even when the RT capacity at that plant is not fully used.

a Formulate this linear programming model.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock