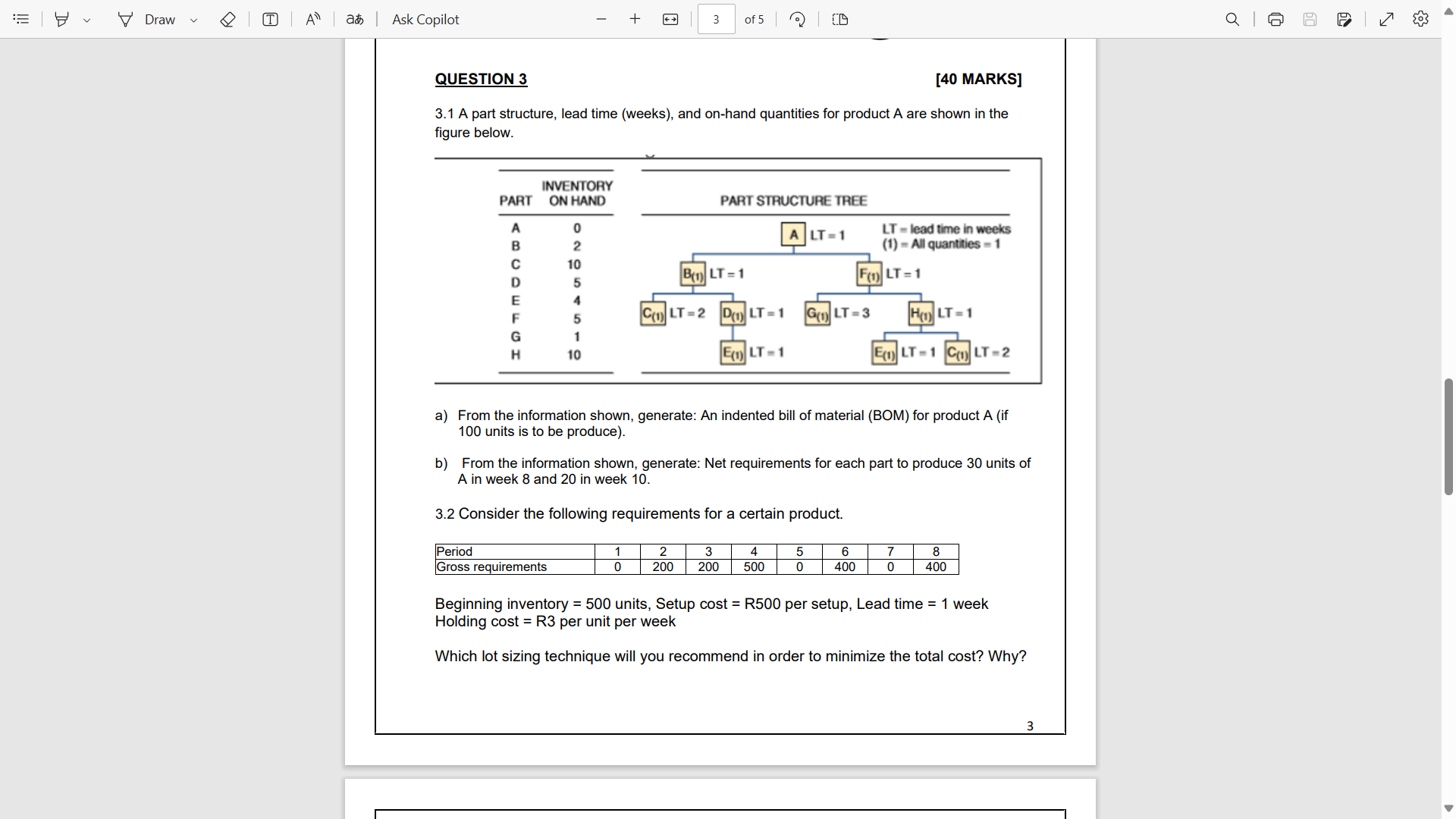

Question: 1 4 . 1 4 A part structure, lead time ( weeks ) , and on - hand quantities for product A are shown in

A part structure, lead time weeks and onhand quantities for product A are shown in Figure From the information shown, generate: a An indented bill of material for product A if units are to be produced see Figure in Chapter as an example of a BOM b Net requirements for each part to produce units of A in week and in week Information for Problems and QUESTION

MARKS

A part structure, lead time weeks and onhand quantities for product A are shown in the

figure below.

a From the information shown, generate: An indented bill of material BOM for product if

units is to be produce

b From the information shown, generate: Net requirements for each part to produce units of

A in week and in week

Consider the following requirements for a certain product.

Beginning inventory units, Setup cost R per setup, Lead time week

Holding cost R per unit per week

Which lot sizing technique will you recommend in order to minimize the total cost? Why?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock